Method for preparing tungsten diselenide nanoflower

A technology of tungsten diselenide and nanoflowers, which is applied in the direction of binary selenium/tellurium compounds, metal selenides/tellurides, etc., can solve the problems of high requirements for reaction atmosphere, high reaction temperature, and high preparation temperature, and achieve easy-to-obtain raw materials The effect of low cost, mild reaction conditions and uniform scale distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Step 1: Add 0.3869g H 2 SeO 3 Dissolve in 50ml of N,N-dimethylformamide (DMF), add 0.3299g Na while stirring 2 WO 4 2H 2 After O, a mixed solution is obtained;

[0023] Step 2: Transfer the mixed solution in step 1 to a 100ml polytetrafluoroethylene reactor, and react at a temperature of 200°C for 48 hours;

[0024] Step 3: after the temperature in the reaction kettle of step 2 is naturally cooled to room temperature, the black product is collected by suction filtration, and the product is washed with deionized water and ethanol respectively, and after vacuum drying, tungsten diselenide (WSe 2 ) nanoflowers.

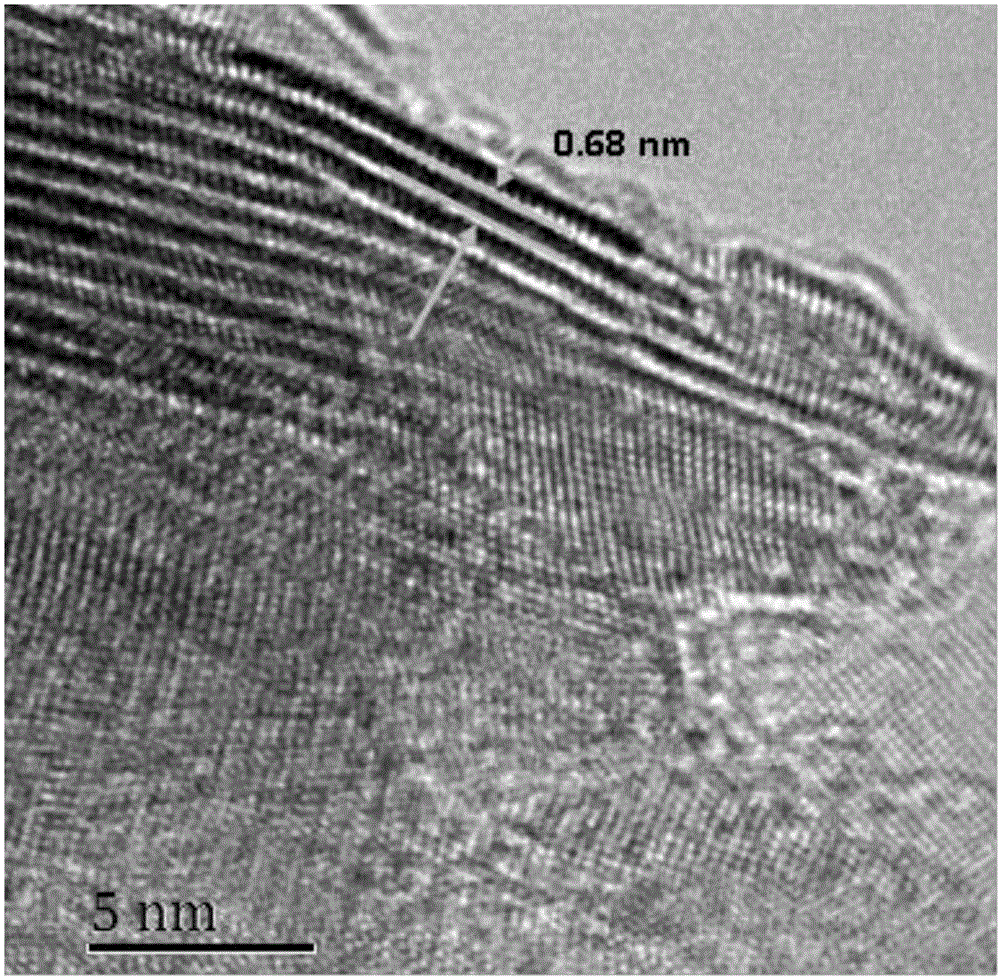

[0025] like figure 1 Shown: the reactant of embodiment 1 is the X-ray diffraction (XRD) pattern of the final product after reacting under the condition of 200 ℃ for 48 hours at a temperature, as can be seen from the figure that the product is WSe with better crystallization 2 , and there is no impurity.

Embodiment 2

[0027] Step 1: Add 0.3869g H 2 SeO 3 Dissolve in 50ml of N,N-dimethylformamide (DMF), add 0.3299g Na while stirring 2 WO 4 2H 2 After O, a mixed solution is obtained;

[0028] Step 2: Transfer the mixed solution in step 1 to a 100ml polytetrafluoroethylene reactor, and react at a temperature of 220°C for 36 hours;

[0029] Step 3: after the temperature in the reaction kettle of step 2 is naturally cooled to room temperature, the black product is collected by suction filtration, and the product is washed with deionized water and ethanol respectively, and after vacuum drying, tungsten diselenide (WSe 2 ) nanoflowers.

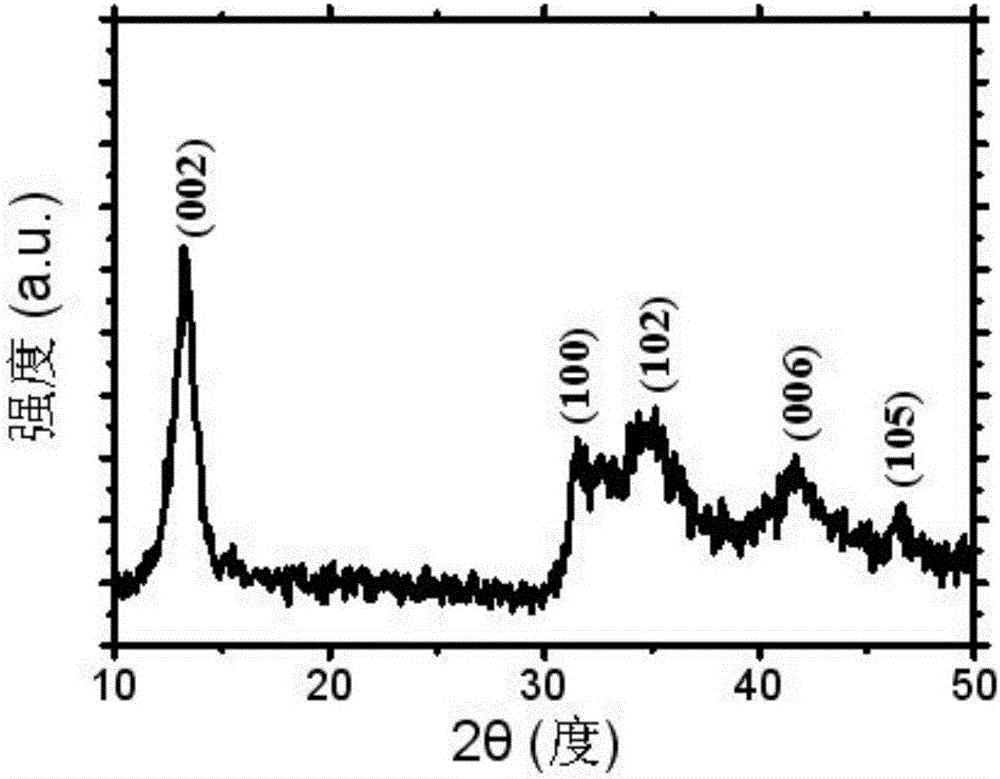

[0030] like figure 2 Shown: the Raman spectrogram of the final product after the reaction of the reactant in Example 2 was reacted at 220°C for 36 hours, as can be seen from the figure, at 247cm -1 WSe 2 Obvious Raman characteristic peak E 1 2g .

Embodiment 3

[0032] Step 1: Add 0.6449g H 2 SeO 3 Dissolve in 50ml of N,N-dimethylformamide (DMF), add 0.3299g Na while stirring 2 WO 4 2H 2 After O, a mixed solution is obtained;

[0033] Step 2: Transfer the mixed solution in step 1 to a 100ml polytetrafluoroethylene reactor, and react at a temperature of 220°C for 24 hours;

[0034]Step 3: after the temperature in the reaction kettle of step 2 is naturally cooled to room temperature, the black product is collected by suction filtration, and the product is washed with deionized water and ethanol respectively, and after vacuum drying, tungsten diselenide (WSe 2 ) nanoflowers.

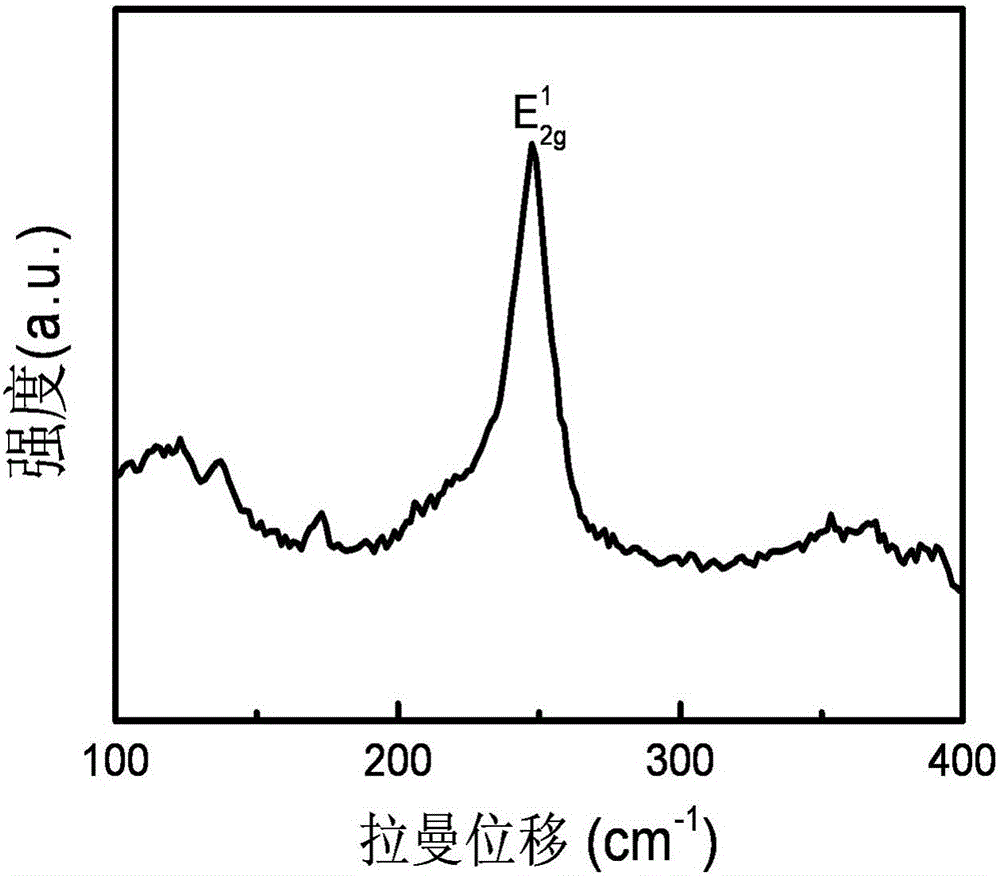

[0035] like image 3 As shown, the scanning electron microscope (SEM) figure of the final product after the reaction of the reactant in Example 3 was reacted for 24 hours under the condition of 220 ° C, it can be seen from the figure that the product is uniform in size and evenly distributed. 2 composed of nanoflowers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com