Preparation method of water-soluble fluorinated graphene

A fluorinated graphene, water-soluble technology, applied in the field of materials, can solve the problems of high risk of operation, high risk, poor dispersion of fluorinated graphene, etc., and achieve the effect of simple process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

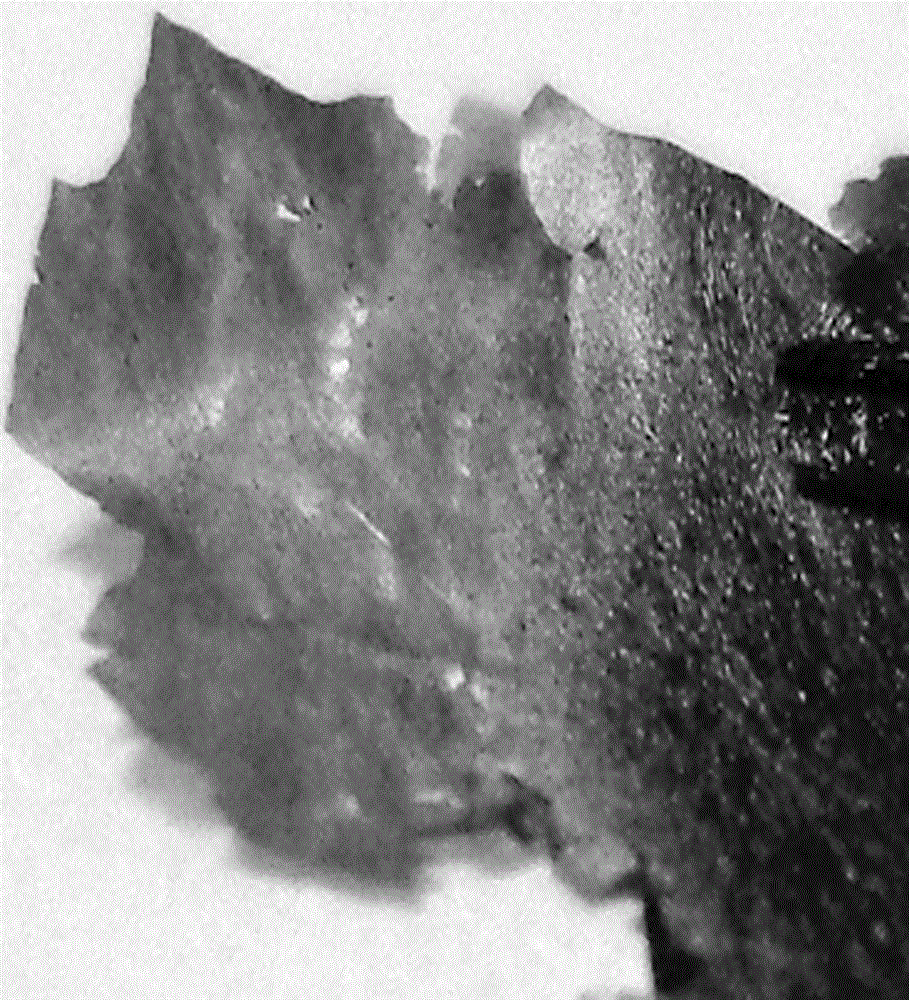

Image

Examples

Embodiment 1

[0030] The present embodiment provides a kind of preparation method of water-soluble fluorinated graphene, and concrete steps comprise:

[0031] Synthesis of graphene oxide: Weigh 2.0 g of flake graphite and 1.0 g of sodium nitrate, add them to 46 mL of concentrated sulfuric acid, slowly add 6 g of potassium permanganate in an ice-water bath, and control the temperature of the reaction solution to 15 ℃ for stirring reaction for 2 hours, then the temperature of the reaction solution was raised to 40 ℃ to react until the solution turns yellow to obtain a yellow suspension, add 92 mL of deionized water to the yellow suspension and raise the temperature to 90 ℃ for 2 hours. After the reaction was completed and cooled to room temperature, 15 mL of hydrogen peroxide solution was added to the reaction solution for centrifugation. precipitation;

[0032] The lower precipitate was washed three times with deionized water and hydrochloric acid with a mass fraction of 5%, and then t...

Embodiment 2

[0039] This embodiment provides a kind of preparation method of water-soluble fluorinated graphene, and concrete steps are roughly the same as the steps in embodiment 1, and difference is that the raw material ratio and parameter in each step are different:

[0040] In the synthesis step of graphene oxide, the temperature of the reaction solution after controlling the reaction for 2 hours is 30°C until the solution is yellow;

[0041] In the preparation step of the water-soluble fluorinated graphene, the concentration of the graphene oxide solution is 0.5 mg / mL, the mass fraction of the nitric acid in the reaction solution system is 10%, the mass fraction of the hydrofluoric acid 1%.

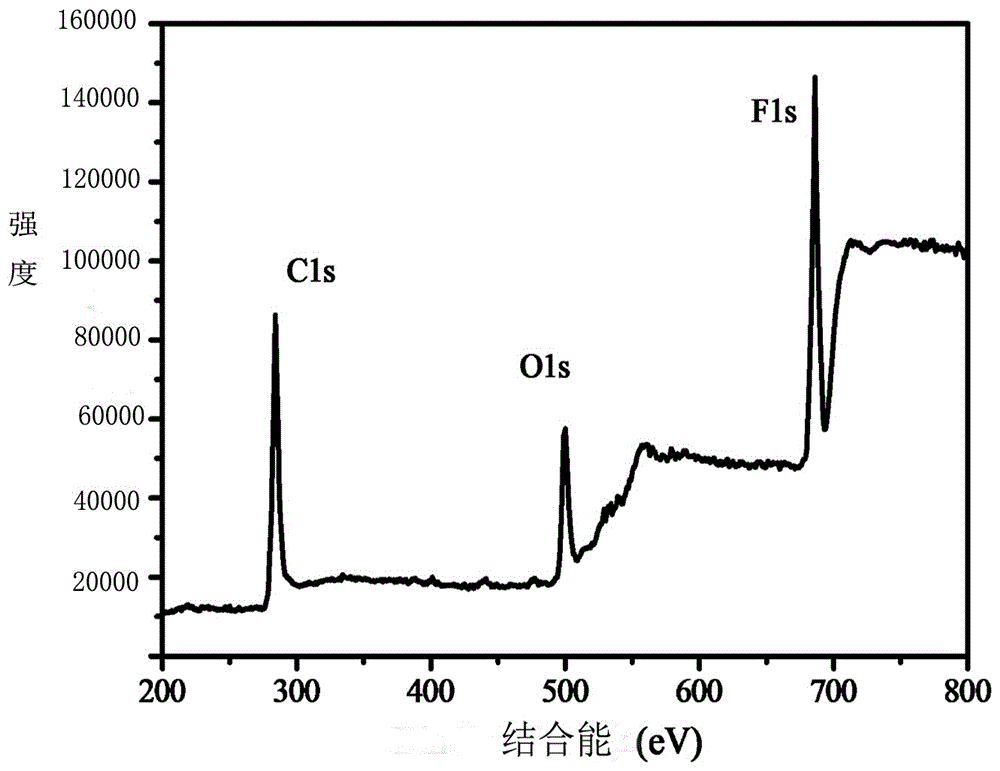

[0042] The water-soluble fluorinated graphene provided in this embodiment is detected by infrared, and at 1000cm -1 ~1250cm -1 The peak representing the C-F structure appeared in the range, thus indicating that the fluorination process of graphene oxide was successfully realized, thereby prepa...

Embodiment 3

[0044] This embodiment provides a kind of preparation method of water-soluble fluorinated graphene, and concrete steps are roughly the same as the steps in embodiment 1, and difference is that the raw material ratio and parameter in each step are different:

[0045] In the synthesis step of graphene oxide, 1.0 g of dried flake graphite was added to a four-necked flask filled with a mixture of 1.0 g of sodium nitrate and 30 mL of concentrated sulfuric acid, ultrasonically mixed evenly, stirred in an ice-water bath and slowly added Potassium permanganate 6.0 g, and the temperature of control reaction solution is 10 ℃ for stirring reaction for 2 hours, then the temperature of the reaction solution was raised to 35 ℃ to react until the solution turns yellow to obtain a yellow suspension, add 100 mL of deionized water to the yellow suspension and heat up to 90 ℃ for 2 hours. After the reaction was completed and cooled to room temperature, 15 mL of hydrogen peroxide solution was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com