Preparation method of cellular three-dimensional graphene

A graphene and honeycomb technology, which is applied in the field of preparation of honeycomb three-dimensional graphene, can solve the problems of difficult mass production, excessive waste liquid, and increase the complexity of the production process, and achieve easy mass production, avoiding the experimental process, and synthesizing The method is simple and efficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Step A. Preparation of graphene oxide.

[0025] Step A1. Weigh flake graphite powder, concentrated sulfuric acid, concentrated phosphoric acid, potassium permanganate, deionized water, hydrogen peroxide, and dilute hydrochloric acid as raw materials; wherein, the ratio of flake graphite powder to concentrated sulfuric acid is 1.5 g: 180 mL, The ratio of flake graphite powder to concentrated phosphoric acid is 1.5 g: 20 mL, the ratio of graphite powder to potassium permanganate is 1.5 g: 9 g, and the concentration of hydrogen peroxide is 35%;

[0026] Step A2. In a water bath at room temperature, add concentrated sulfuric acid and concentrated phosphoric acid mixed acid into the three-necked bottle, mechanically stir until the temperature of the mixed acid returns to room temperature, add flake graphite powder, slowly add potassium permanganate in portions, and the temperature of the system rises slowly , control the addition rate of potassium permanganate so that the sy...

Embodiment 2

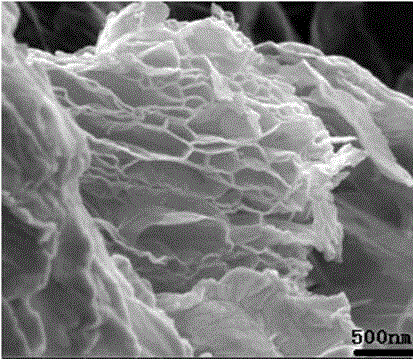

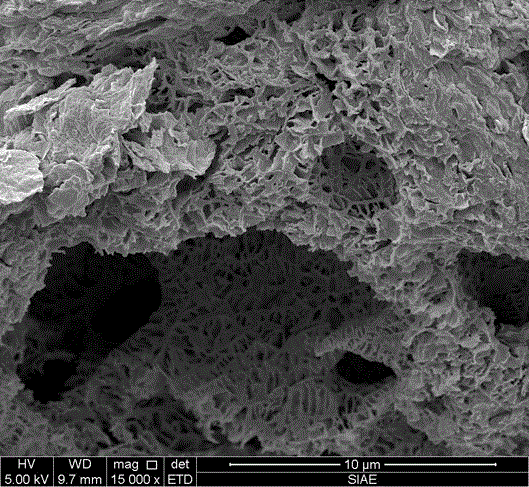

[0035] Carry out according to the method shown in embodiment 1, difference is only in the add-on of metal-free phthalocyanine in B1 step be 0.5g, the inert gas of step C is nitrogen+hydrogen, and its gas flow is 50 cm 3 min -1 . After solid-phase cleavage and self-assembly, the morphology of the obtained honeycomb three-dimensional graphene is as follows: figure 2 As shown, its specific surface area is 298.2 m 2 g -1 .

Embodiment 3

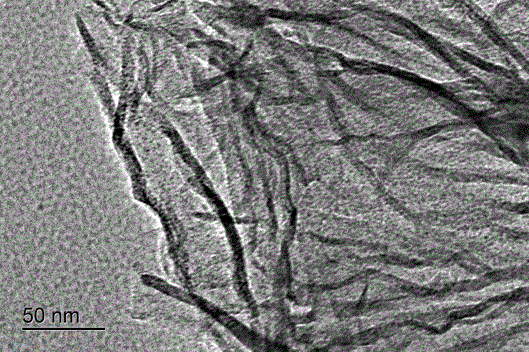

[0037] Implement according to the method shown in Example 1, the difference is only that the addition of metal-free phthalocyanine is 3g in the B1 step, and the inert gas of step C is nitrogen, and its gas flow is 10 cm 3 min -1 . After self-assembly by solid-phase cleavage, the transmission electron microscope image of the obtained honeycomb three-dimensional graphene is as follows image 3 , with a specific surface area of 251.6 m 2 g -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com