Fertilizer for promoting growth of rice

A fertilizer and rice technology, applied in the field of fertilizers for promoting the growth of rice, can solve the problems of soil hardening in paddy fields, harm of snails, and high fertilizer costs, and achieve the effects of reducing production costs, increasing effective components, and improving fertilizer efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

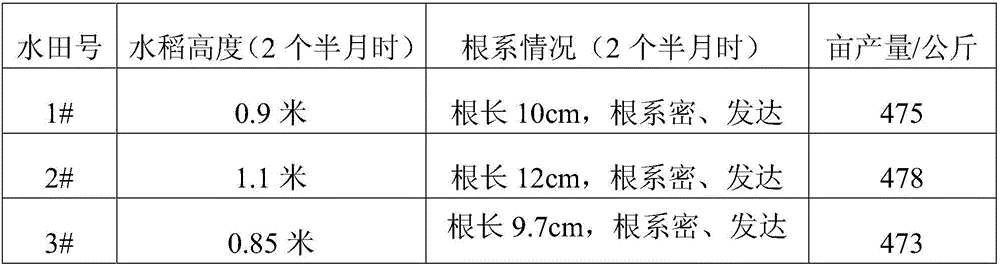

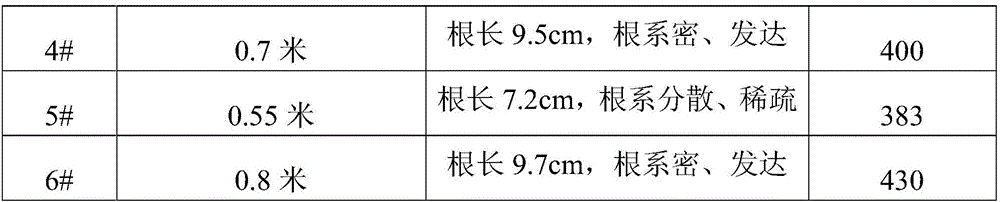

Image

Examples

Embodiment 1

[0023] Soak fresh Osmanthus in lime water with a mass concentration of 35% for 3 hours, dry until the surface of Osmanthus is dry, then put the dried Osmanthus in an oven and keep the temperature at 50°C for 6 hours, take it out and put it in Pulverize in a pulverizer, then grind and pass through a 100-mesh sieve, ready for use; dry the fresh algae until the water content is 40%, then mix it with quartz sand evenly, put it in an oven and keep the temperature at 85°C for 2 hours. Grind and pass through a 220-mesh sieve, ready for use.

[0024] Take kg as the unit and according to the weight ratio, weigh the required raw materials of each component: nitrogen fertilizer ammonium chloride 100kg, phosphate fertilizer monoammonium phosphate 40kg, zinc fertilizer zinc oxide 10kg, the above-mentioned spare Osmanthus japonica 10kg, the above-mentioned spare algae 3kg and Tea polyphenols 0.1kg, then mix and stir the raw materials of each component evenly, and use it in powder or granule...

Embodiment 2

[0026] Soak fresh Osmanthus in lime water with a mass concentration of 50% for 1 hour, dry until the surface of Osmanthus is dry, then put the dried Osmanthus in an oven and keep the temperature at 70°C for 3 hours, take it out and put it in Pulverize in a pulverizer, then grind and pass through a 180-mesh sieve, ready for use; dry the fresh algae until the water content is 50%, then mix it with quartz sand evenly, put it in an oven and dry it at 85°C for 3 hours, Grind and pass through a 180-mesh sieve, ready to use.

[0027] Take kg as the unit and according to the weight ratio, weigh the required raw materials of each component: 200kg of nitrogen fertilizer urea, 80kg of phosphate fertilizer diammonium phosphate, 20kg of zinc fertilizer zinc chloride, 20kg of the above-mentioned spare Osmanthus japonica, 5kg of the above-mentioned spare algae and tea Polyphenol 0.7kg, then mix and stir the raw materials of each component evenly, use after powder or granule, all can.

Embodiment 3

[0029] Soak fresh Osmanthus in lime water with a mass concentration of 42.5% for 2 hours, dry until the surface of Osmanthus is anhydrous, then put the dried Osmanthus in an oven and keep the temperature at 60°C for 4.5 hours, take it out and put it Put it into a pulverizer and grind it, and then grind it through a 140-mesh sieve to get it, and use it for later use; dry the fresh algae until the water content is 45%, then mix it with quartz sand evenly, put it in an oven and dry it at 85°C for 3 hours , ground through a 200-mesh sieve, ready to use.

[0030] Take kg as the unit and according to the weight ratio, weigh the required raw materials of each component: 150kg of nitrogen fertilizer ammonium nitrate, 60kg of phosphate fertilizer diammonium phosphate, 15kg of zinc fertilizer zinc sulfide, 15kg of the above-mentioned spare Osmanthus osmanthus, 4kg of the above-mentioned spare algae and tea Polyphenol 0.4kg, then mix and stir each component raw material evenly, use after...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com