Environment-friendly economical polyarylether and preparation method thereof

An economical technology of polyarylether, which is applied in the field of environmentally friendly and economical polyarylether and its preparation, can solve the problems of difficult ultra-large-scale industrial scale-up, low catalyst recovery rate, high production cost, etc., and reduce energy consumption , Reduce the frequency of solvent recovery, the effect of high molecular weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

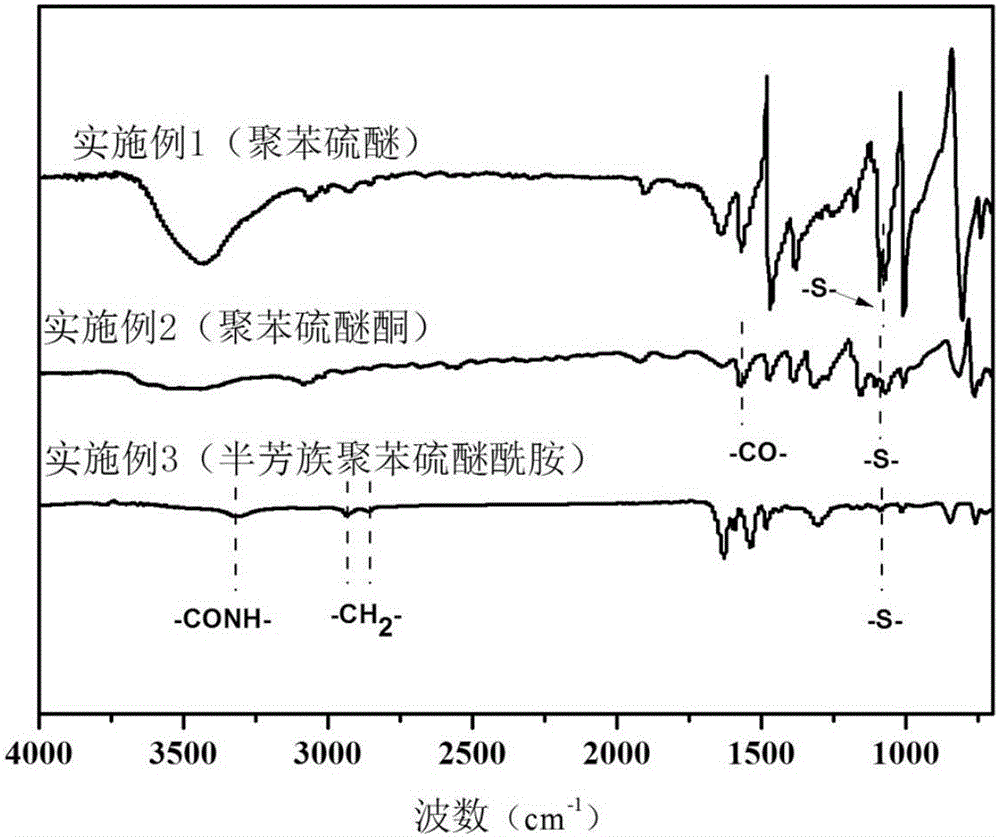

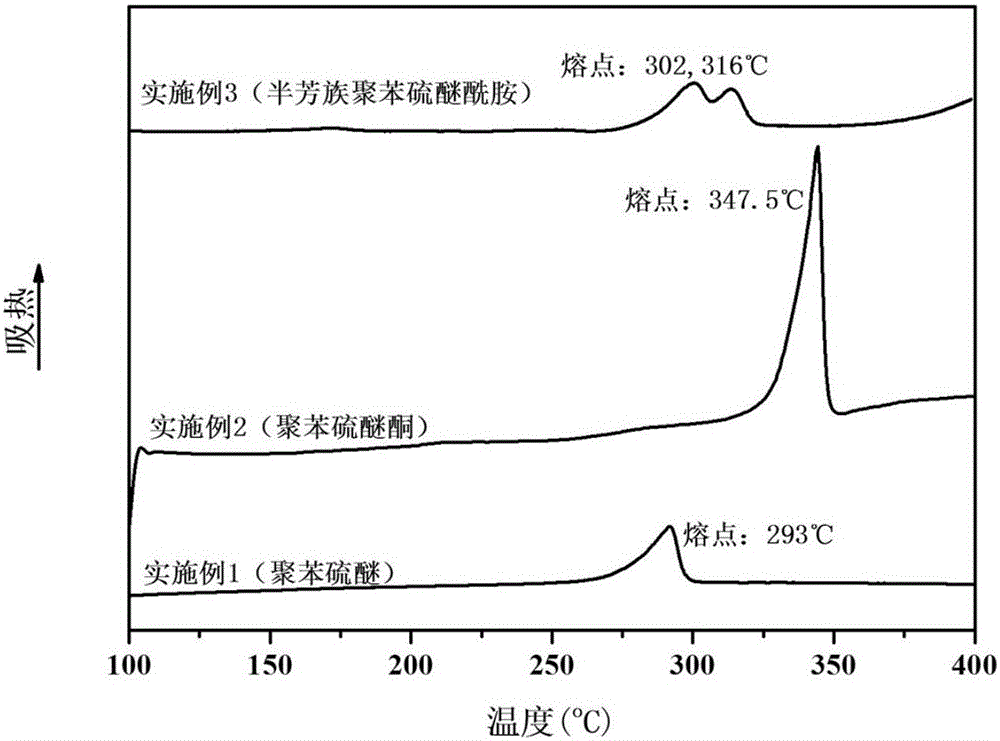

Embodiment 1

[0043]1kg of lithium acetate, 0.1kg of sodium hydroxide, 500kg of the reaction filtrate (mixed solution of hexamethylphosphoric triamide and catalyst) used in the last preparation of polyphenylene sulfide and 130kg of sodium sulfide with a water content of 40% were added to the reaction In the kettle, under the protection of nitrogen, dehydrate at a temperature of 200°C for 2 hours to obtain a dehydrated reaction solution. When the temperature of the above solution drops to 160°C, add 147kg of p-dichlorobenzene and react at a temperature of 230°C for 3 hours. Keep at ℃ for 1h, cool down to 90℃, filter the reaction solution, add 0.1kg18-crown-6 to the filtered liquid to precipitate the dissolved metal salt in the filtrate, and then remove the precipitated precipitate by filtration to obtain the second filtration Liquid, add 0.1kg polyferric chloride in the filtrate for the second time to precipitate the oligomers in the filtrate, separate the oligomers and the liquid by centrifu...

Embodiment 2

[0045] Add 0.2kg sodium tartrate, 5kg potassium hydroxide, 1200kg of the reaction filtrate (N-cyclohexylpyrrolidone and catalyst mixed solution) and 82.4kg of sodium hydrosulfide with a water content of 32% after the polyphenylene sulfide ketone was prepared last time In the reaction kettle, under the protection of nitrogen, dehydration reaction was carried out at a temperature of 185°C for 1.5h to obtain a dehydrated reaction solution. When the temperature of the above solution dropped to 160°C, 218kg of 4,4'-difluorobenzophenone was added to the React at a temperature of 205°C for 2 hours, keep at a temperature of 270°C for 3 hours, cool down to 100°C, filter the reaction solution, add 0.1kg of polyvinyl alcohol to the filtered liquid to precipitate the dissolved metal salt in the filtrate, and then remove the precipitate Remove by filtration, obtain the filtrate for the second time, add 0.2kg ammonium polyphosphate in the filtrate for the second time to precipitate the oligo...

Embodiment 3

[0047] With 0.5kg lithium phosphate, 12kg magnesium hydroxide, the reaction filtrate (N-methyl caprolactam and catalyst mixed solution) and the sodium sulfide 130kg of 40% that 1800kg prepare semiaromatic polyphenylene sulfide amide last time use Put it into the reaction kettle, and under the protection of nitrogen, dehydrate at a temperature of 195°C for 2 hours to obtain a dehydrated reaction solution. When the temperature of the above solution drops to 120°C, add 360kg of 1,6-bis(4-fluorobenzoyl) Hexamethylenediamine, react at a temperature of 200°C for 2h, keep at a temperature of 235°C for 6h, cool down to 90°C, filter the reaction solution, add 0.5kg polydopamine to the filtered liquid to precipitate the dissolved metal salt in the filtrate, and then Remove the precipitated precipitate by filtration to obtain the second filtrate, add 0.1kg polyacrylamide to the second filtrate to precipitate oligomers in the filtrate, and separate the precipitated oligomers and liquid by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com