Preparation method of low-VOC glass fiber reinforced polypropylene halogen-free flame-retardant composite material

A flame retardant composite material, polypropylene technology, applied in the field of polymer materials, can solve the problems of VOC, high calorific value, ability discount of adsorption and degradation, etc., to achieve lasting and effective secondary pollution, improvement of retarding performance, simple method effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

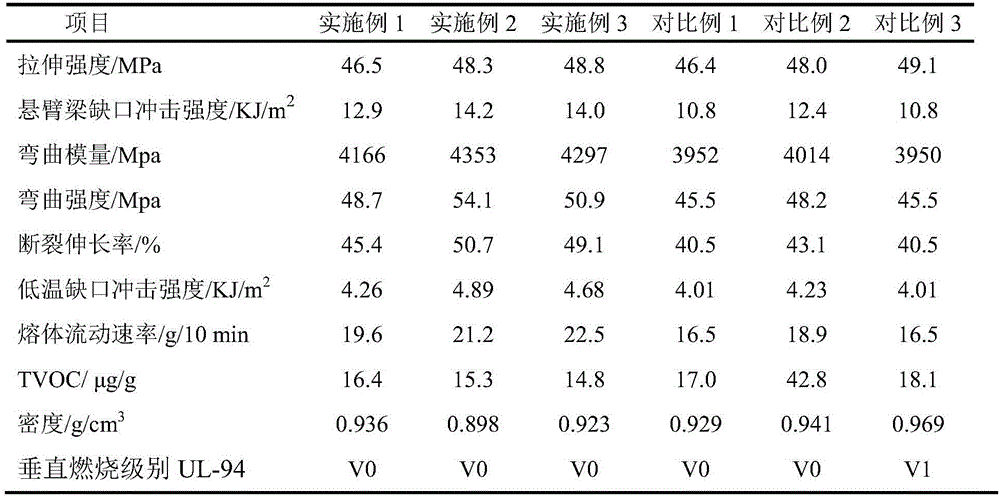

Examples

Embodiment 1

[0027] First prepare glass fiber reinforced polypropylene masterbatch, weigh dry polypropylene 4000g, long glass fiber 5100g, talcum powder 420g, antioxidant 1010 60g, anti-ultraviolet additive CYASORB UV-V680 60g, ammonium polyphosphate 150g and zinc borate 20g After mixing evenly, add the twin-screw extruder to melt and blend at 195°C, extrude through the extruder, cool and pelletize to obtain glass fiber reinforced polypropylene masterbatch, and the content of bromine in the reactive low bromine phosphorus nitrogen flame retardant 200ppm;

[0028] Next, prepare hollow glass microsphere master batches, weigh and mix 720g of dried hollow glass microspheres and 330g of VOC inhibitors evenly, then add them to a twin-screw extruder for melting and blending at 195°C, extrude, cool and pelletize to obtain hollow glass Microbead masterbatch, wherein the mass of the 720g hollow glass microsphere surface compatibilizer PP-g-MAH accounts for 320g, and the VOC inhibitor is composed of ...

Embodiment 2

[0031] First prepare glass fiber reinforced polypropylene masterbatch, weigh dry polypropylene 6500g, long glass fiber 2300g, antioxidant 1010 20g, anti-ultraviolet additive CYASORB UV-V680 40g, N, N-p-phenylenediamine (2- After 200 g of tetraethyl hydroxy)dibenzylphosphonate and 40 g of zinc borate are uniformly mixed, they are added to a twin-screw extruder at 210 ° C for melt blending, extruded through the extruder, cooled and pelletized to obtain glass fiber reinforced polypropylene masterbatch;

[0032] Next, prepare hollow glass microsphere master batches, weigh and mix 650g of dried hollow glass microspheres and 230g of VOC inhibitors evenly, then add them to a twin-screw extruder for melting and blending at 195°C, extrude, cool and pelletize to obtain hollow glass Microbead masterbatch, wherein the quality of the 650g hollow glass microsphere surface compatibilizer PP-g-MAH accounts for 170g, and the VOC inhibitor is composed of nano Composed of photocatalyst, attapulg...

Embodiment 3

[0035] First prepare glass fiber reinforced polypropylene masterbatch, weigh dry polypropylene 6700g, long glass fiber 3400g, talcum powder 200g, antioxidant 1010 40g, anti-ultraviolet additive CYASORB UV-V680 30g, reactive low-bromine phosphorus-nitrogen barrier After 270g of fuel and 30g of zinc borate are mixed evenly, they are added to a twin-screw extruder at 210°C for melt blending, extruded through the extruder, cooled and pelletized to obtain glass fiber reinforced polypropylene masterbatch;

[0036] Next, prepare hollow glass microsphere master batches, weigh and mix 1050g of dried hollow glass microspheres and 320g of VOC inhibitors evenly, then add them to a twin-screw extruder for melt blending at 195°C, extrude, cool and pelletize to obtain hollow glass Microbead masterbatch, wherein the quality of the 1050g hollow glass microsphere surface compatibilizer PP-g-MAH accounts for 320g, and the VOC inhibitor is composed of nano Composed of photocatalyst, attapulgite, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com