A kind of semiconductor device and its manufacturing method, electronic device

A manufacturing method and semiconductor technology, applied in semiconductor devices, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problem of poor off-state characteristics of MOSFET devices, short-channel effect and leakage-induced barrier reduction, and device performance degradation, etc. The problem is to reduce the degradation of carrier mobility, reduce the channel electric field, and reduce the leakage current.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

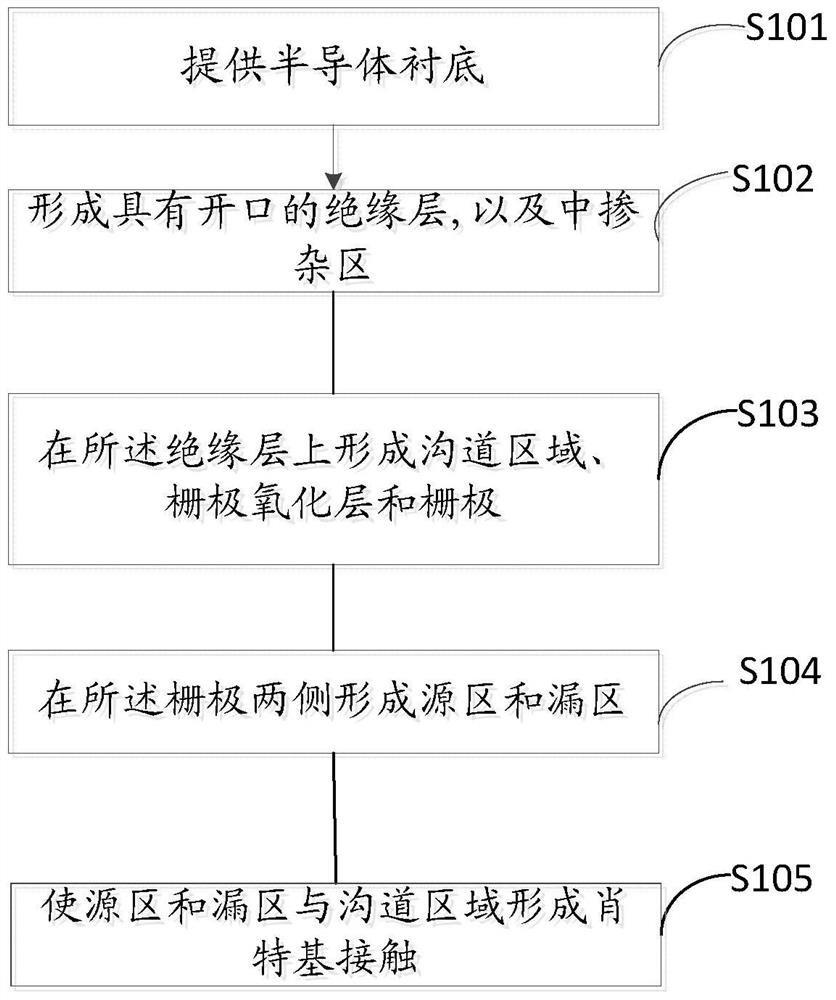

[0046] Figure 2a - Figure 2m A cross-sectional view of a device obtained at each step in a process flow for fabricating a semiconductor device according to an embodiment of the present invention. The following will refer to Figure 2a - Figure 2m The manufacturing method of the semiconductor device of the present invention will be described in detail.

[0047] First, as Figure 2a As shown, a semiconductor substrate 200 is provided. The semiconductor substrate 200 may be at least one of the materials mentioned below: silicon, germanium, silicon germanium, and the like. In addition, other devices, such as PMOS and NMOS transistors, may be formed on the semiconductor substrate. An isolation structure may be formed in the semiconductor substrate, and the isolation structure may be a shallow trench isolation (STI) structure or a localized silicon oxide (LOCOS) isolation structure. CMOS devices, such as transistors (eg, NMOS and / or PMOS), etc., may also be formed in the semic...

Embodiment 2

[0076] The present invention also provides a semiconductor device 300 fabricated by the method described in Embodiment 1, comprising: a semiconductor substrate 200, an insulating layer 201 having an opening formed on the semiconductor substrate 200, a silicon layer located in the opening, and The channel region 211, the gate oxide layer 212 and the gate electrode 218 are located above the opening, and the source electrode 217A and the drain electrode 217B are located on both sides of the gate electrode 218; wherein, the surface layer of the semiconductor substrate in the opening and under the opening is formed The heavily doped region 204 ; the source 217A and the drain 217B form Schottky contacts with the channel region 211 .

[0077] Optionally, the source electrode 217A and the drain electrode 217B are formed with silicide.

[0078] Optionally, the insulating layer 201 is a silicon dioxide layer.

[0079] Optionally, the channel region 211 is an undoped layer or a lightly ...

Embodiment 3

[0084] The present invention further provides an electronic device including the aforementioned semiconductor device. Figure 4 It is a schematic structural diagram of an electronic device according to an embodiment of the present invention. Due to the inclusion of the aforementioned semiconductor device, the self-heating effect, the leakage-induced barrier lowering effect, and the sub-threshold characteristics of the device can be improved, and the electronic device also has the above-mentioned advantages.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com