Nitrogen-doped porous carbon/sulfur composite material and preparing method and application thereof

A technology of nitrogen-doped porous carbon and composite materials, applied in non-aqueous electrolyte battery electrodes, electrical components, battery electrodes, etc., to achieve good cycle stability, high discharge specific capacity, and enhanced electron and ion transport effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

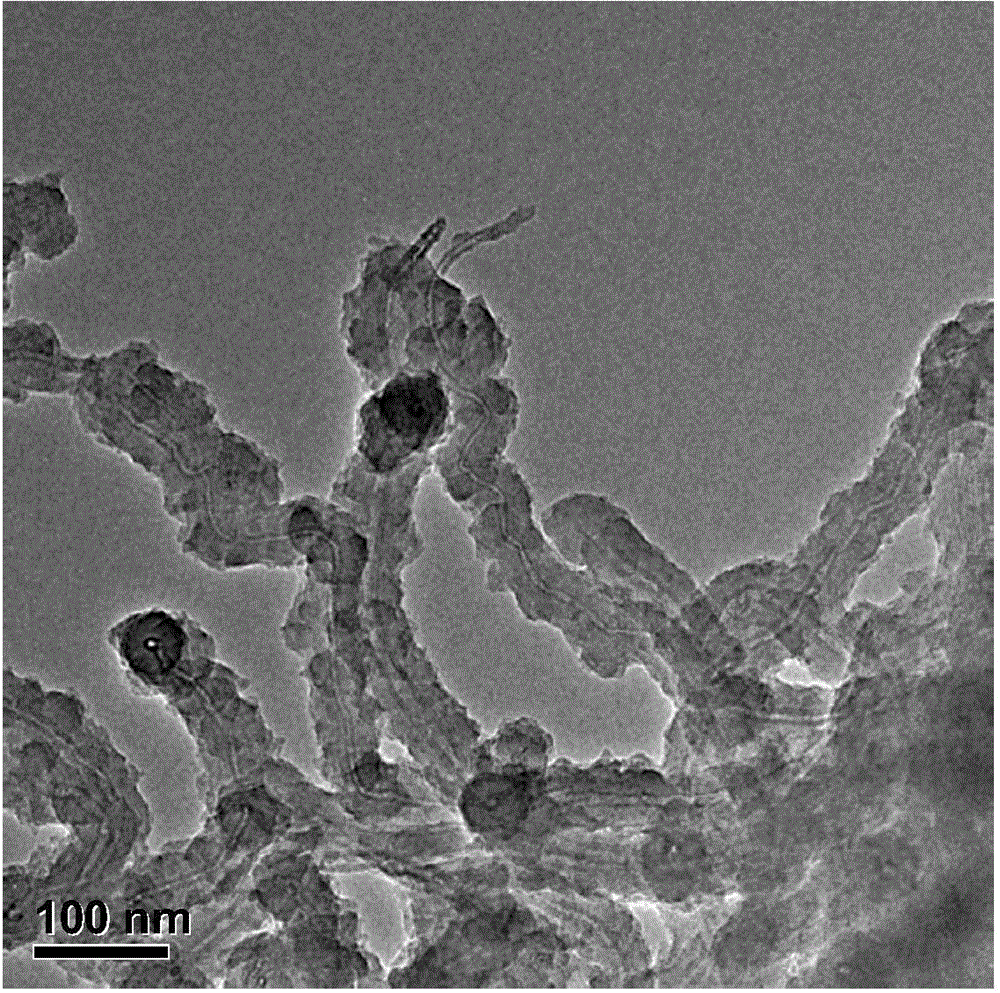

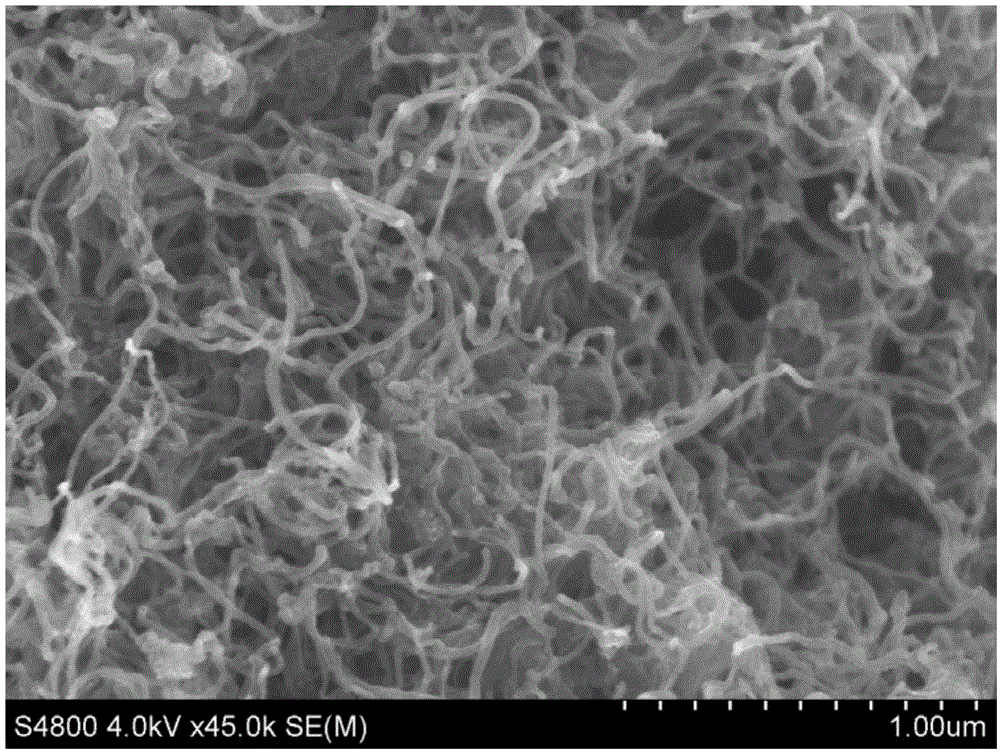

[0037] (1) Melamine, m-phthalaldehyde, and carbon nanotubes are put into thick-walled pressure-resistant reaction flasks with dimethyl sulfoxide (0.05g / mL according to the concentration of melamine) according to the mass ratio of 100:80:24, After reacting at 180° C. for 3 days under stirring, wash with dichloromethane and separate the solid;

[0038] (2) Put the obtained solid into a tube furnace and adjust the argon flow rate to 0.12 sccm and raise the temperature to 400°C for 5 hours to obtain a nitrogen-doped porous carbon material;

[0039] (3) After mixing the obtained carbon material and elemental sulfur in a mortar at a mass ratio of 2:3, put it into a closed glass tube, raise the temperature to 155°C at a heating rate of 5°C / min and keep it warm for 20h.

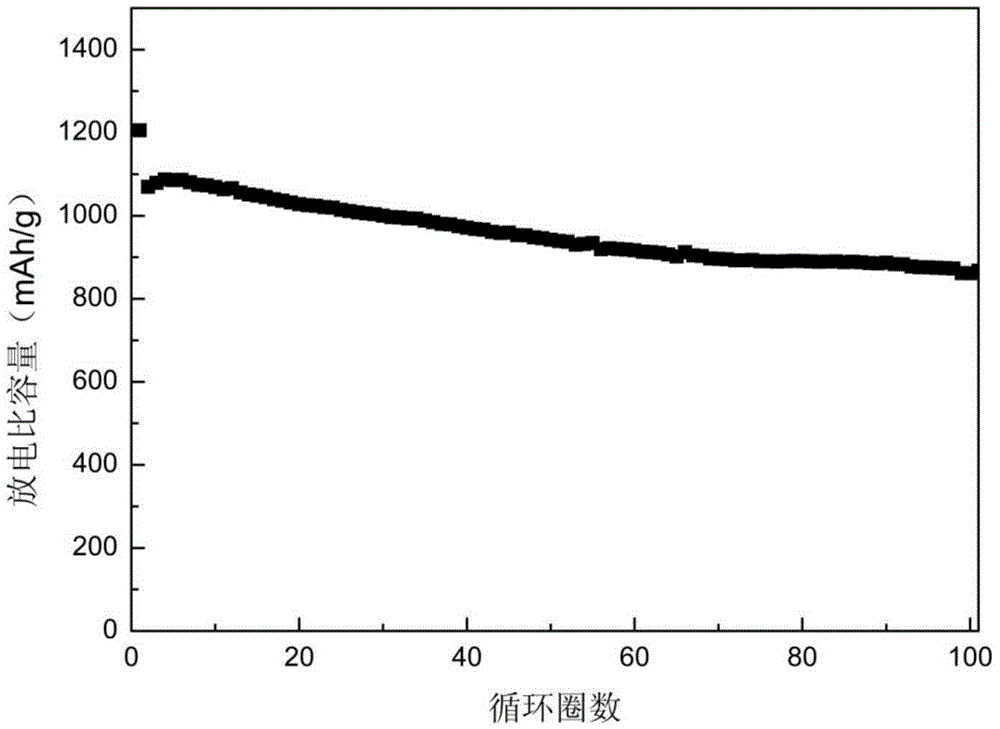

[0040] After naturally cooling to room temperature, acetylene black and polyvinylidene fluoride were slurried with NMP at a mass ratio of 8:1:1, mixed uniformly and coated on aluminum foil to obtain the lithium-sulfu...

Embodiment 2

[0042] (1) Put benzidine, m-phthalaldehyde, carbon nanofibers in a mass ratio of 100:120:24, and dimethyl sulfoxide (according to the concentration of benzidine is 0.10g / mL) into a thick-walled pressure-resistant reaction bottle , after reacting at 180° C. for 3 days under stirring, wash with dichloromethane and separate the solid;

[0043] (2) Put the obtained solid into a tube furnace and adjust the argon flow rate to 0.12 sccm, heat up to 600° C. for 3.5 hours, and obtain a nitrogen-doped porous carbon material;

[0044] (3) After mixing the obtained carbon material and elemental sulfur in a mortar at a mass ratio of 3:4, put it into a closed glass tube, raise the temperature to 165°C at a heating rate of 5°C / min and keep it warm for 15h.

[0045]After naturally cooling to room temperature, acetylene black and polyvinylidene fluoride were slurried with NMP at a mass ratio of 8:1:1, mixed uniformly and coated on aluminum foil to obtain the lithium-sulfur battery cathode mate...

Embodiment 3

[0047] (1) Put aniline, benzaldehyde, and carbon nanofibers in a thick-walled pressure-resistant reaction bottle according to the mass ratio of 100:120:24, and dimethyl sulfoxide (0.06g / mL according to the concentration of aniline), and stir After reacting at 180° C. for 3 days, wash with dichloromethane and separate the solid;

[0048] (2) Put the obtained solid into a tube furnace and adjust the argon flow rate to 0.12 sccm, heat up to 800° C. for 4.5 hours, and obtain a nitrogen-doped porous carbon material;

[0049] (3) After mixing the obtained carbon material and elemental sulfur in a mortar at a mass ratio of 4:3, put it into a closed glass tube, raise the temperature to 185°C at a heating rate of 5°C / min and keep it warm for 15 hours.

[0050] After naturally cooling to room temperature, acetylene black and polyvinylidene fluoride were slurried with NMP at a mass ratio of 8:1:1, mixed uniformly and coated on aluminum foil to obtain the lithium-sulfur battery cathode ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com