Sun cream for sensitive skin

A sunscreen and sensitivity technology, applied in skin care preparations, cosmetic preparations, medical preparations containing active ingredients, etc., can solve the problems that sunscreen products are irritating, not suitable for highly sensitive, easy to damage skin, etc. , to achieve the effect of protecting DNA damage in cells, restoring normal physiological functions of the body, and improving the ability to resist ultraviolet radiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

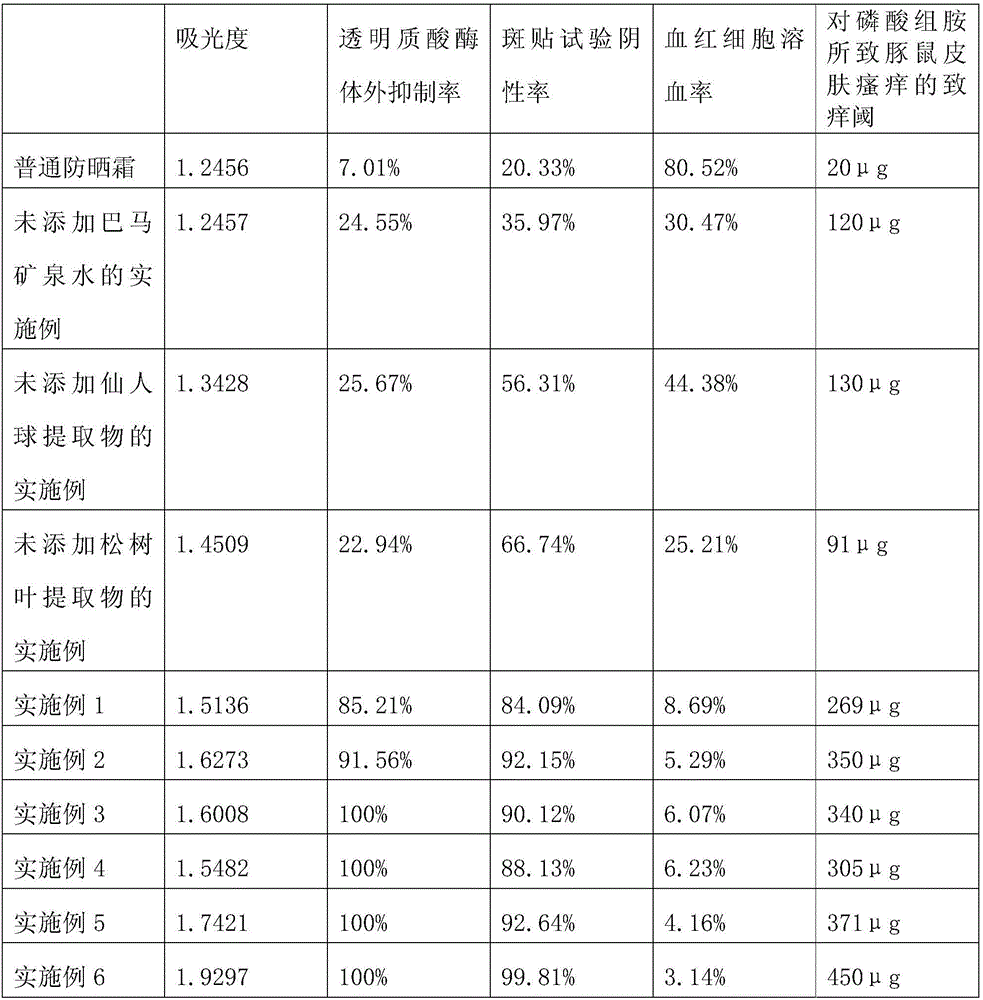

Examples

Embodiment 1

[0030] (1) Preparation of raw materials:

[0031] Preparation of prickly pear extract: Take 20g of prickly pear powder and put it into a beaker, add 100mL of aqueous solution, soak for 5h, hot soak in a water bath at 60°C for 5h, after natural cooling, take the filtrate by suction filtration, put it in a vacuum drying oven under pressure Negative 0.05MPa, dry and concentrate at 50-60°C for 12 hours, then take out the concentrated solution, add 150mL of 60% ethanol solution for precipitation, and then centrifuge at a speed of 2000r / min for 20min in a centrifuge to take the precipitate The product was washed twice with pure water, and dried in an infrared drying oven at 50°C for 12 hours to obtain the prickly pear extract.

[0032] Preparation of pine leaf extract: crush dry pine leaves, pass through a 10-mesh sieve, take 20g and put them into a 100mL round-bottomed flask, add extraction solvent for pre-soaking for 1h, and then move the round-bottomed flask into an ultrasonic re...

Embodiment 2

[0035] (1) Preparation of raw materials:

[0036] Preparation of prickly pear extract: put 20 g of prickly pear powder into a beaker, add 100 mL of ethanol solution with a mass fraction of 50%, soak for 7 hours, heat soak in a water bath at 65°C for 3 hours, and after natural cooling, take the filtrate by suction filtration, put in Dry and concentrate in a vacuum oven at a pressure of minus 0.06 MPa and a temperature of 52°C for 14 hours, then take out the concentrated solution, add 150 mL of ethanol solution with a mass fraction of 65% to precipitate, and then centrifuge at a speed of 2500 r / min in a centrifuge After 18 minutes, the precipitate was washed twice with pure water, dried in an infrared drying oven at 55°C for 10 hours, and the prickly pear extract was obtained.

[0037] Preparation of pine leaf extract: crush dry Changbaishan larch leaves, pass through a 10-mesh sieve, take 20g and put them into a 100mL round-bottom flask, add extraction solvent for pre-soaking f...

Embodiment 3

[0040] (1) Preparation of raw materials:

[0041] Preparation of prickly pear extract: put 20 g of prickly pear powder into a beaker, add 100 mL of ethyl acetate solution with a mass fraction of 20%, soak for 8 hours, heat extract in a water bath at 70°C for 3 hours, cool naturally, and take the filtrate by suction. Put it into a vacuum drying oven at a pressure of minus 0.08MPa and a temperature of 54°C to dry and concentrate for 18 hours, then take out the concentrated solution, add 150mL of ethanol solution with a mass fraction of 70% for precipitation, and then centrifuge at 3000r / min Centrifuge at a high speed for 12 minutes, wash the precipitate twice with pure water, and dry it in an infrared drying oven at 60°C for 8 hours to obtain the prickly pear extract.

[0042] Preparation of pine leaf extract: crush dry five-needle pine leaves, pass through a 10-mesh sieve, take 20g and put it into a 100mL round-bottomed flask, add extraction solvent to pre-soak for 1h, then mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com