Nano-antibacterial coating preparation method based on quaternized chitosan half-bred micelles

A technology of quaternized chitosan and antibacterial coating, which is applied in the direction of coating, electrolytic coating, electrophoretic plating, etc., can solve the problems of hindering the biochemical action and physiological function of bacteria, and achieve strong practicability and applicability. The effect of abundant sources and low experimental cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A method for preparing a nano-antibacterial coating based on quaternized chitosan hybrid micelles, the specific preparation steps are as follows:

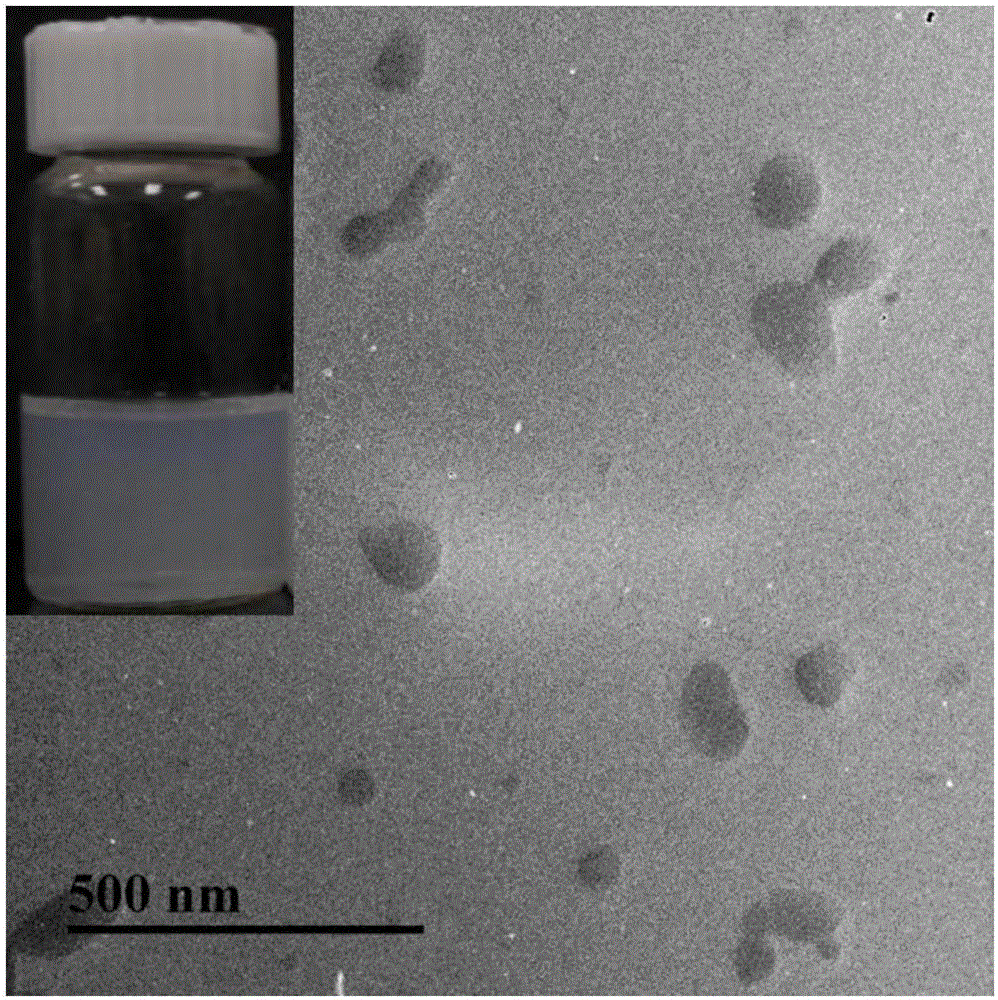

[0020] (1) Preparation of hybrid micellar solution: quaternized chitosan was dissolved in 1% glacial acetic acid aqueous solution to form a 3 mg / mL quaternized chitosan solution, and L-cysteine was dissolved in water Form a 3mg / mL L-cysteine solution, mix the prepared two solutions in equal volumes, add a certain amount of nano-zinc oxide, so that the concentration of nano-zinc oxide is 0.8mg / mL, keep stirring, and after mixing evenly, adjust The pH of the above mixed solution is 6, which promotes the self-assembly of quaternized chitosan, small molecule L-cysteine and nano-zinc oxide, and continues to stir for 10 minutes to fix the hybrid micelle morphology and obtain a hybrid micelle solution , the digital photo of the sample and the topography in the dry state are attached figure 1 shown.

[0021] (2) Preparation ...

Embodiment 2

[0023] A method for preparing a nano-antibacterial coating based on quaternized chitosan hybrid micelles, the specific steps are as follows:

[0024] (1) Preparation of hybrid micellar solution: quaternized chitosan was dissolved in 1% glacial acetic acid aqueous solution to form a 3 mg / mL quaternized chitosan solution, and L-cysteine was dissolved in water Form a 5 mg / mL L-cysteine solution, mix the prepared two solutions at a volume ratio of 1:2, add a certain amount of nano-zinc oxide so that the concentration of nano-zinc oxide is 1.0 mg / mL, keep stirring, and wait to mix After uniformity, adjust the pH=7 of the above-mentioned mixed solution to promote the self-assembly of quaternized chitosan, small molecule L-cysteine and nano-zinc oxide, and continue to stir for 20 minutes to fix the hybrid micelle morphology and obtain the hybrid micelle. micelle solution.

[0025] (2) Preparation of nanometer antibacterial coating: first, the cobalt-based alloy is ultrasonical...

Embodiment 3

[0027] A method for preparing a nano-antibacterial coating based on quaternized chitosan hybrid micelles, the specific steps are as follows:

[0028] (1) Preparation of hybrid micellar solution: quaternized chitosan was dissolved in 1% glacial acetic acid aqueous solution to form a 5 mg / mL quaternized chitosan solution, and L-cysteine was dissolved in water Form a 3mg / mL L-cysteine solution, mix the prepared two solutions at a volume ratio of 1:3, add a certain amount of nano-zinc oxide so that the concentration of nano-zinc oxide is 3mg / mL, continue to stir, and mix evenly Afterwards, adjust the pH=8 of the above-mentioned mixed solution to promote the self-assembly of quaternized chitosan, small molecule L-cysteine and nano-zinc oxide, and continue to stir for 30 minutes to fix the hybrid micelle morphology and obtain a hybrid micellar solution.

[0029] (2) Preparation of nano-antibacterial coating: first, 316L stainless steel was ultrasonically cleaned with acetone ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com