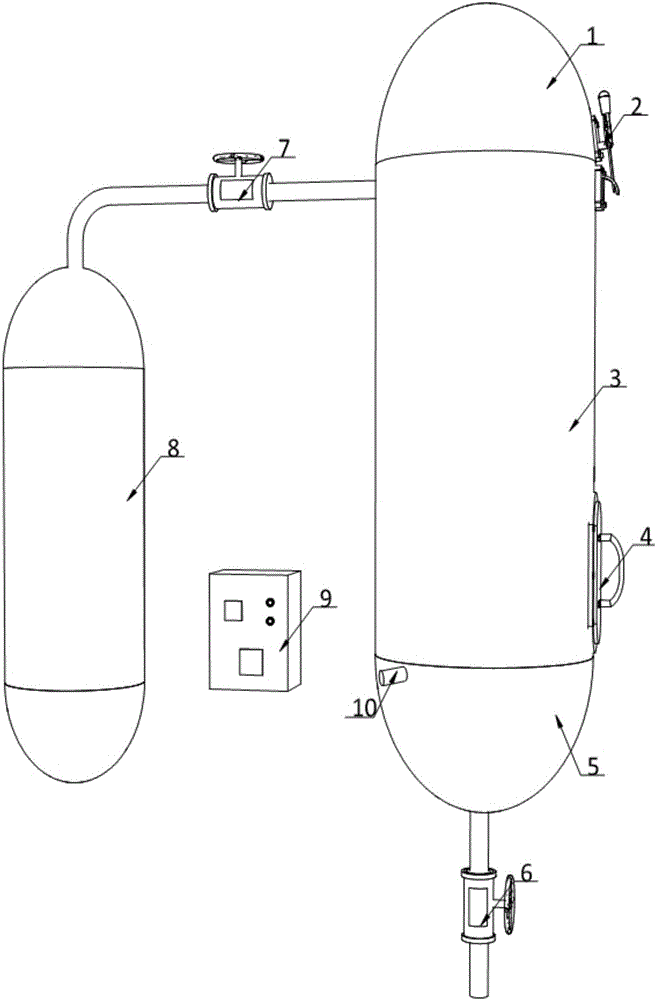

Special reaction device for curing agent for repair of soil heavy metal pollution and production method thereof

A technology for repairing soil and reaction devices, applied in chemical instruments and methods, chemical/physical/physicochemical fixed reactors, chemical/physical processes, etc., can solve problems such as increasing the hardness of soil aquifers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

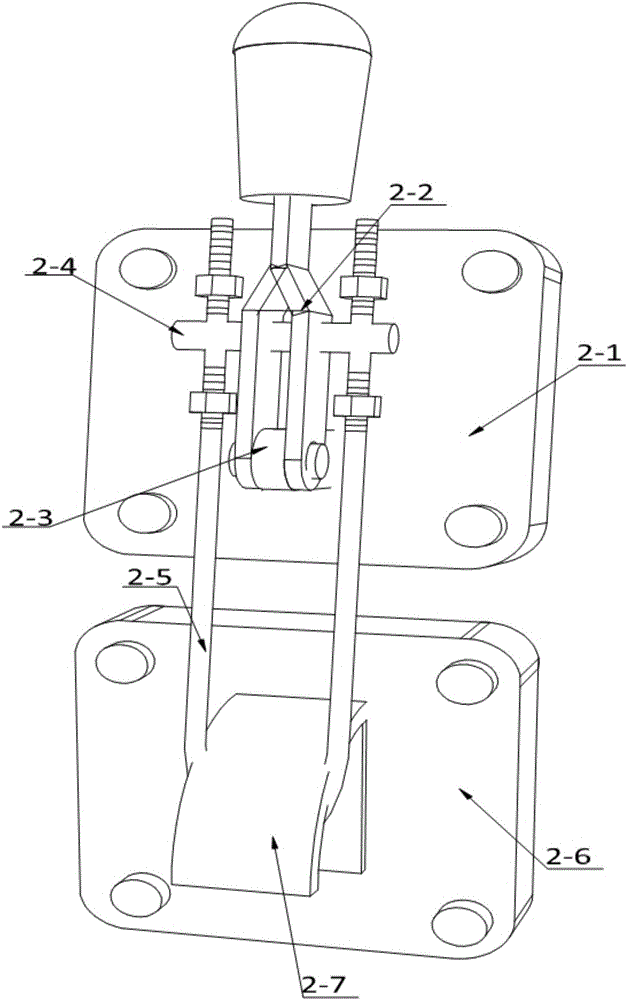

Method used

Image

Examples

Embodiment 1

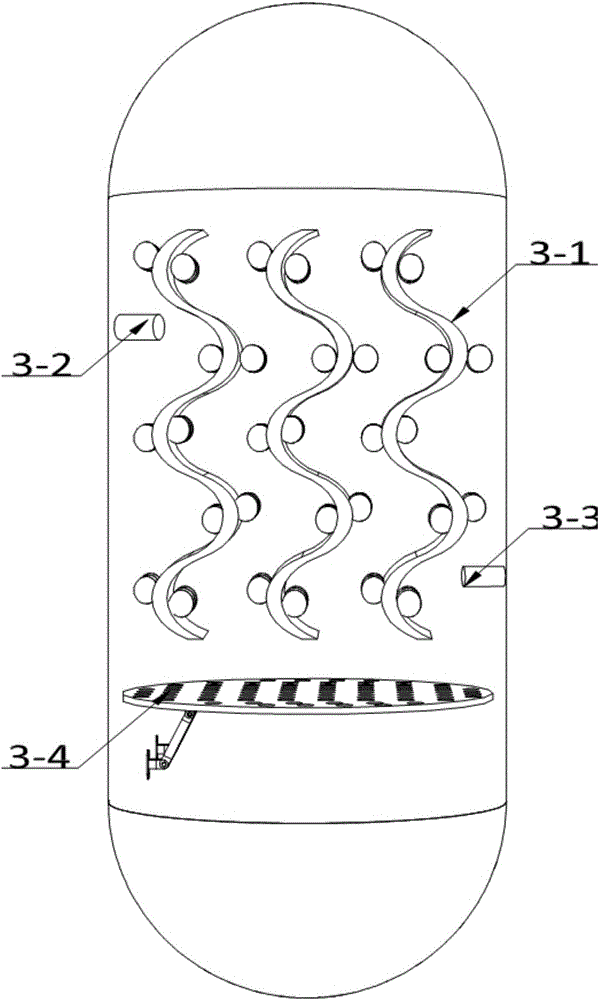

[0060] Manufacture the esterification reaction plate 3-1-1 of the present invention according to the following steps, and in parts by weight:

[0061] Step 1: Add 786 parts of ultrapure water with a conductivity of 3.22μS / cm into the reactor, start the stirrer in the reactor at a speed of 46rpm, start the heating pump, and raise the temperature in the reactor to 56°C; add in order 70 parts of 4-isopropyl-2-propenyltoluene, 84 parts of dextro-trans-2,2-dimethyl-3-(2-methyl-1-propenyl)cyclopropanecarboxylic acid, 2- 26 parts of 2-(4-morpholinyl)ethyl methyl-2-acrylate, stir until completely dissolved, adjust the pH value to 5.3, adjust the stirrer speed to 186rpm, the temperature is 87°C, and the esterification reaction is 9 hours ;

[0062] Step 2: Take 28 parts of 2,3,5,6-tetrafluorobenzyl (1R,3S)-3-(2,2-dichlorovinyl)-2,2-dimethylcyclopropanecarboxylate , 112 parts of (α-cyano-1-methyl)butenyl-2,2-dimethyl-3-(2,2-dichlorovinyl)cyclopropanecarboxylate are pulverized, and the...

Embodiment 2

[0067] Manufacture the esterification reaction plate 3-1-1 of the present invention according to the following steps, and in parts by weight:

[0068]Step 1: Add 1145 parts of ultrapure water with a conductivity of 4.23μS / cm into the reactor, start the stirrer in the reactor at a speed of 84rpm, start the heating pump, and raise the temperature in the reactor to 76°C; add in sequence 113 parts of 4-isopropyl-2-propenyltoluene, 114 parts of dextro-trans-2,2-dimethyl-3-(2-methyl-1-propenyl)cyclopropanecarboxylic acid, 2- 53 parts of 2-(4-morpholino)ethyl methyl-2-acrylate, stir until completely dissolved, adjust the pH value to 6.4, adjust the speed of the agitator to 225rpm, the temperature is 127°C, and the esterification reaction takes 18 hours ;

[0069] Step 2: Take 52 parts of 2,3,5,6-tetrafluorobenzyl (1R,3S)-3-(2,2-dichlorovinyl)-2,2-dimethylcyclopropanecarboxylate , 195 parts of (α-cyano-1-methyl)butenyl-2,2-dimethyl-3-(2,2-dichlorovinyl)cyclopropanecarboxylate are pu...

Embodiment 3

[0074] Manufacture the esterification reaction plate 3-1-1 of the present invention according to the following steps, and in parts by weight:

[0075] Step 1: Add 1561 parts of ultrapure water with a conductivity of 5.62μS / cm into the reactor, start the stirrer in the reactor at a speed of 108rpm, start the heating pump, and increase the temperature in the reactor to 89°C; add in sequence 156 parts of 4-isopropyl-2-propenyl toluene, 144 parts of dextro-trans-2,2-dimethyl-3-(2-methyl-1-propenyl) cyclopropanecarboxylic acid, 2- 78 parts of 2-(4-morpholino)ethyl methyl-2-acrylate, stir until completely dissolved, adjust the pH value to 7.2, adjust the stirrer speed to 268rpm, the temperature is 148°C, and the esterification reaction takes 28 hours ;

[0076] Step 2: Take 79 parts of 2,3,5,6-tetrafluorobenzyl (1R,3S)-3-(2,2-dichlorovinyl)-2,2-dimethylcyclopropanecarboxylate , 269 parts of (α-cyano-1-methyl)butenyl-2,2-dimethyl-3-(2,2-dichlorovinyl)cyclopropanecarboxylate are pul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com