Method for extracting anthocyanin from nitraria tangutorum peel residues

A technology of Nitraria rind and anthocyanins, applied in chemical instruments and methods, azo dyes, organic dyes, etc., can solve the problems of long extraction time and low extraction efficiency, and achieve improved dissolution rate, improved extraction rate, and improved Yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

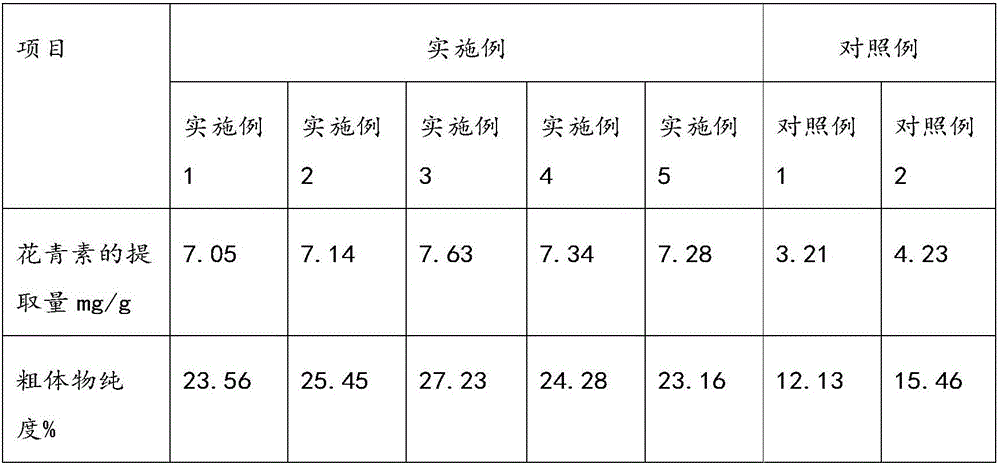

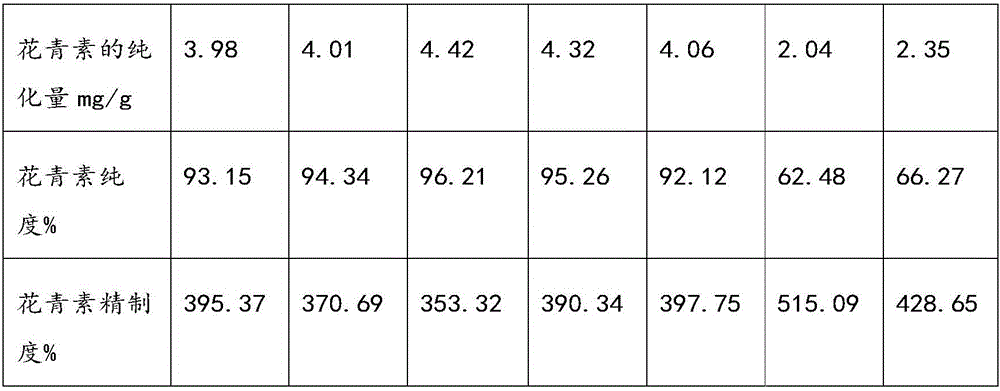

Examples

Embodiment 1

[0042] This embodiment provides a method for extracting anthocyanins from Nitraria rind residue, comprising the following steps:

[0043] (1) Pretreatment step: freeze the Nitraria rind residue at -40°C for 5 hours, and then dry it to constant weight by vacuum drying under reduced pressure. Wherein the parameters of the decompression vacuum drying method are: the degree of vacuum is 0.05MPa, and the temperature is 10°C. Then the dried Nitraria pericarp residue was crushed to 80 mesh to obtain Nitraria pericarp residue powder.

[0044] (2) Enzymolysis step: mix Nitraria pericarp residue powder with cellulase for enzymolysis treatment, the amount of cellulase added is 0.2% of the weight of Nitraria pericarp residue powder, the enzymolysis temperature is 40°C, and the enzymolysis time for 60 minutes, followed by filtration to obtain Nitraria rind residue enzymatic hydrolysis solution.

[0045] (3) Extraction step: after mixing the enzymatic hydrolysis solution of Nitraria peric...

Embodiment 2

[0048] This embodiment provides a method for extracting anthocyanins from Nitraria rind residue, comprising the following steps:

[0049] (1) Pretreatment step: freeze the residue of Nitraria rind at -30°C for 7 hours, and then dry it to constant weight by vacuum drying under reduced pressure. Wherein the parameters of the decompression vacuum drying method are: the degree of vacuum is 0.2 MPa, and the temperature is 2°C. Then the dried Nitraria pericarp residue was crushed to 70 mesh to obtain Nitraria pericarp residue powder.

[0050] (2) Enzymolysis step: the Nitraria peel residue powder is mixed with cellulase and xylanase for enzymolysis treatment. Wherein the added amount of cellulase is 0.04% of the weight of Nitraria pericarp residue powder, and the added amount of xylanase is 0.12% of the weight of Nitraria pericarp residue powder. The enzymolysis temperature is 42° C., and the enzymolysis time is 50 minutes, followed by filtration to obtain the enzymolysis solution...

Embodiment 3

[0054] This embodiment provides a method for extracting anthocyanins from Nitraria rind residue, comprising the following steps:

[0055] (1) Pretreatment step: freeze the residue of Nitraria rind at -25°C for 7.5 hours, and then dry it to constant weight by vacuum drying under reduced pressure. Wherein the parameters of the decompression vacuum drying method are: the degree of vacuum is 0.15MPa, and the temperature is 6°C. Then crush the dried Nitraria pericarp residue to 60 mesh to obtain Nitraria pericarp residue powder.

[0056] (2) Enzymolysis step: the Nitraria peel residue powder is mixed with cellulase and xylanase for enzymolysis treatment. Wherein the added amount of cellulase is 0.06% of the weight of Nitraria pericarp residue powder, and the added amount of xylanase is 0.1% of the weight of Nitraria pericarp residue powder. The enzymolysis temperature is 42.5° C., and the enzymolysis time is 45 minutes, followed by filtration to obtain the enzymolysis solution of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com