Method for producing super-hydrophobic polytetrafluoroethylene films through glass template process

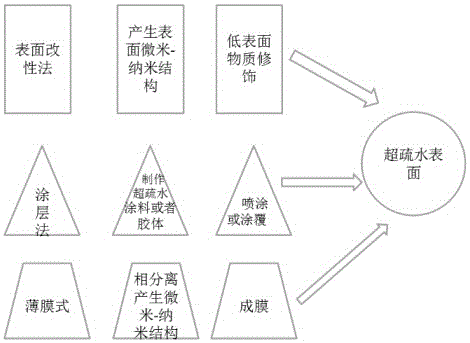

A polytetrafluoroethylene and super-hydrophobic technology, which is applied in the field of preparing super-hydrophobic polytetrafluoroethylene films by glass stencil method, can solve the problems of easy wear and tear of imprinting stencils, low reusability, small single production area, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

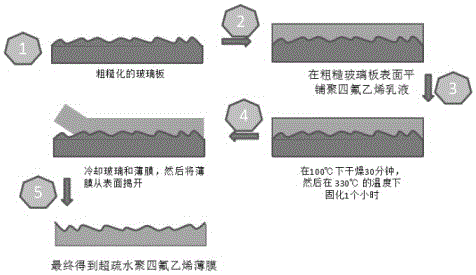

[0028] 1. Preparation of ground glass template: (1) Use redox method to make ground glass, using 15-35% sulfuric acid (or hydrochloric acid, nitric acid) with a concentration of 40-60% as oxidant, 5-15% hydrofluoric acid as reducing agent, 40-60% concentration is a mixture of 5-10% ethanol as a buffer and 0.03-0.06% ammonium nitrate as a catalyst, soak for 1-2 hours at room temperature (20-30°C), (2) take out the glass and wash with water Surface residues; (3) Dry the glass surface to obtain textured glass.

[0029] 2. Brush or roll coated with 10% PTFE emulsion (Zhejiang Juhua) on the textured side of the glass plate;

[0030] 3. Dry the ground glass loaded with PTFE emulsion at 90-110℃ for 30-100min;

[0031] 4. Put the dry glass plate with PTFE film into an oven at 300-360℃ for 30min;

[0032] 5. Slowly lower the temperature to 100°C and take out the cured glass plate;

[0033] 6. Gently pull out the polytetrafluoroethylene film at a temperature of 10-50℃ to obtain a super-hydropho...

Embodiment 2

[0036] 1. Preparation of the textured glass template: (1) Configure the redox mixed liquid, including: 100g gallic acid, 305ml ethanolamine, 140ml water, 1.3g pyrazine, 0.24ml FC129 (2) Put the glass in the liquid at room temperature (20 -30℃) Soak for 1-2 hours, then take it out; (3) Wash and clean the surface with water, (4) Dry the textured glass surface;

[0037] 2. Brush or roll coated with 25% PTFE emulsion (Zhejiang Juhua) on the textured side of the glass plate;

[0038] 3. Dry the ground glass with PTFE emulsion at 100°C for 60 minutes;

[0039] 4. Put the dry glass plate with PTFE film into an oven at 320℃ to cure for 20 minutes;

[0040] 5. Slowly lower the temperature to 100°C and take out the cured glass plate;

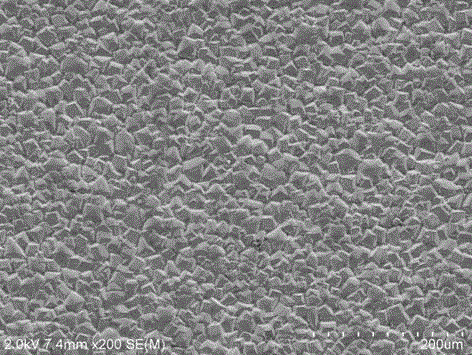

[0041] 6. Pull out the PTFE film gently at a temperature of 25°C to obtain a super-hydrophobic PTFE film on one side. The static contact angle on the surface is 154 degrees and the rolling angle is 5 degrees;

[0042] 7. The glass template can be reused many times....

Embodiment 3

[0044] 1. Preparation of textured glass template: (1) Configure redox mixed liquid, including: 50g HNO 3 [68%], 30gHF[55%], CH 3 COOH 30 g, 0.6gBr 2 (2) Put the glass in the liquid, soak for 2 hours at room temperature, and take it out; (3) Wash the surface with water, (4) Dry the textured glass surface;

[0045] 2. Use 35% PTFE emulsion (Zhejiang Juhua) to brush or roll on the textured side of the glass plate;

[0046] 3. Dry the ground glass with PTFE emulsion at 100°C for 30 minutes;

[0047] 4. Put the dry glass plate with PTFE film into an oven at 300℃ to cure for 40 minutes;

[0048] 5. Slowly lower the temperature to 100°C and take out the cured glass plate;

[0049] 6. Gently pull out the PTFE film at a temperature of 50°C to obtain a super-hydrophobic PTFE film on one side with a static contact angle of 163 degrees and a rolling angle of 6 degrees;

[0050] 7. The glass template can be reused many times.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com