Silk fibroin hydrogel adopting IPN (interpenetrating polymer network) structure and preparation method of silk fibroin hydrogel

A silk fibroin, interpenetrating network technology, applied in medical science, prosthesis, tissue regeneration, etc., can solve the problem of low elastic recovery rate of hydrogel, achieve excellent light transmittance, excellent compressive strength, gel time short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

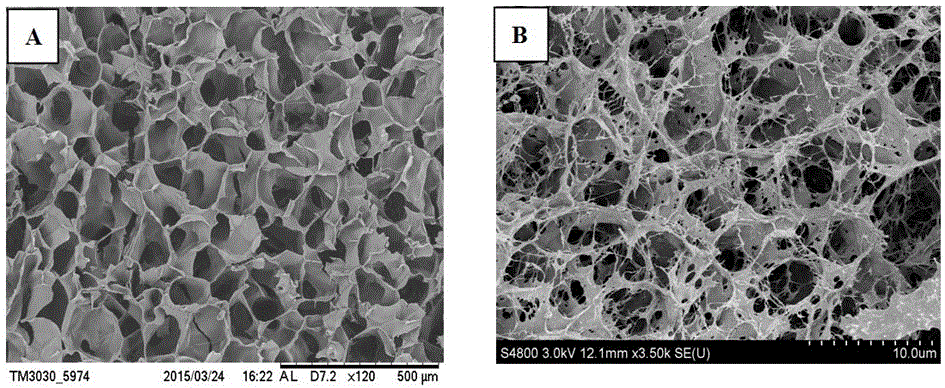

Image

Examples

Embodiment 1

[0022] This embodiment prepares a silk fibroin interpenetrating network hydrogel, and the specific steps are as follows:

[0023] 1. Preparation of silk fibroin solution:

[0024] Weigh 80 g silkworm cocoon shells with a precision balance, configure 4000 milliliters of sodium bicarbonate sodium carbonate aqueous solution with a mass fraction of 0.01MpH=9.5, (add 4000 milliliters of deionized water to stainless steel, 1 gram of sodium carbonate, 3 grams of sodium bicarbonate ), heated to boiling with an induction cooker, then added cocoon shells, adjusted the power of the induction cooker to the lowest level, continued to boil slightly for 30 minutes, took out the silk and cleaned it with deionized water. Repeat the above test three times to remove sericin, then take it out and place it in an oven at 60°C to dry to obtain pure silk fiber. Dissolve pure silk fiber in lithium bromide solution with a concentration of 9.3 mol / L at a bath ratio of 20:150, dissolve in a constant tem...

Embodiment 2

[0031]1. Preparation of silk fibroin solution: weigh 80 g silkworm cocoon shells with a precision balance, configure 4000 milliliters of sodium bicarbonate and sodium carbonate aqueous solution with a mass fraction of 0.01MpH=9.5, (add 4000 milliliters of deionized water and sodium carbonate to stainless steel 1 g, sodium bicarbonate 3 g), heated to boiling with an induction cooker, then added cocoon shells, adjusted the power of the induction cooker to the lowest level, continued to boil slightly for 30 minutes, took out the silk and cleaned it with deionized water. Repeat the above test three times to remove sericin, then take it out and place it in an oven at 60°C to dry to obtain pure silk fiber. Dissolve pure silk fiber in lithium bromide solution with a concentration of 9.3 mol / L at a bath ratio of 20:150, dissolve in a constant temperature magnetic stirrer at 60±2°C for about 1 h, take it out after cooling, put it into a dialysis bag and seal it, Dialyze in deionized wa...

Embodiment 3

[0036] 1. Preparation of silk fibroin solution: weigh 80 g silkworm cocoon shells with a precision balance, configure 4000 milliliters of sodium bicarbonate and sodium carbonate aqueous solution with a mass fraction of 0.01MpH=9.5, (add 4000 milliliters of deionized water and sodium carbonate to stainless steel 1 g, sodium bicarbonate 3 g), heated to boiling with an induction cooker, then added cocoon shells, adjusted the power of the induction cooker to the lowest level, continued to boil slightly for 30 minutes, took out the silk and cleaned it with deionized water. Repeat the above test three times to remove sericin, then take it out and place it in an oven at 60°C to dry to obtain pure silk fiber. Dissolve pure silk fiber in lithium bromide solution with a concentration of 9.3 mol / L at a bath ratio of 20:150, dissolve in a constant temperature magnetic stirrer at 60±2°C for about 1 h, take it out after cooling, put it into a dialysis bag and seal it, Dialyze in deionized w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| elastic recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com