Emulsion pressure-sensitive adhesive and PE protection film prepared from same

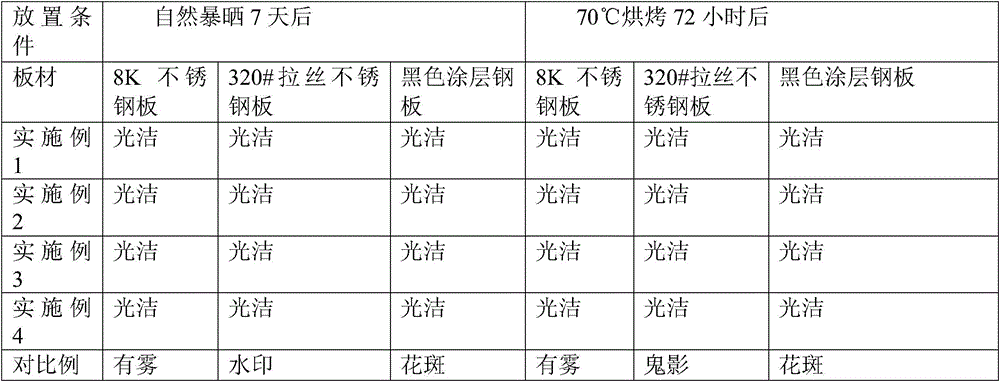

A hydraulic and emulsifier technology, used in pressure-sensitive films/sheets, adhesives, film/sheet adhesives, etc., to solve problems such as pollution, watermarks on product surfaces, mottled or "ghost images, etc." The effect of preventing scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Methyl acrylate 36Kg, methyl methacrylate 4.8Kg, hydroxyethyl methacrylate 0.6Kg, hydroxyethyl acrylate 2Kg, acrylic acid 0.6Kg, γ-glycidyl etheroxypropyl trimethoxysilane (KH560 crosslinking agent) 1Kg, (alkylphenol) allyl polyether sulfate 0.5Kg, allyloxy nonylphenol polyoxyethylene ether sulfate 0.1Kg, azobisisobutylamidine hydrochloride 0.1Kg, water 45Kg, and Emulsion 1 was prepared by conventional emulsion polymerization.

Embodiment 2

[0029] Isooctyl acrylate 18Kg, ethyl acrylate 11.25Kg, isooctyl acrylate 4.8Kg, methyl methacrylate 8.25Kg, hydroxypropyl methacrylate 1Kg, methylol acrylamide 1Kg, acrylic acid 0.45Kg, itaconic acid 0.25 Kg, KH-560 1Kg, 1.5Kg of nonionic emulsifier prepared by EO / PO ring opening, 0.2Kg of anionic emulsifier, 0.1Kg of azobisisobutylamidine hydrochloride, 45Kg of water, according to the conventional emulsion polymerization method Prepare emulsion two.

Embodiment 3

[0031] Lauryl acrylate 38.02Kg, butyl acrylate 2.5Kg, isooctyl acrylate 2Kg, methacrylic acid 1Kg, glycidyl methacrylate 0.25Kg, maleic anhydride 0.1Kg, KH-560 1Kg, sodium alkyl sulfate 0.5Kg, Sodium dodecylsulfonate 0.5Kg, allyloxy fatty alcohol polyoxyethylene ether sulfate 1.4Kg, azobisisobutylamidine hydrochloride 0.5Kg, water 45Kg, prepared emulsion three by conventional emulsion polymerization method .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com