Preparing method for Gd-Zn-Cu-In-S@ZnS core-shell quantum dot with adjustable emission wavelength

A technology of core-shell quantum dots and emission wavelengths, which is applied in chemical instruments and methods, luminescent materials, nanotechnology, etc., and can solve problems such as emission wavelengths not reaching the near-infrared region and the impact of fluorescence quantum yields.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] 1) 5mmol gadolinium chloride GdCl 3 .6H 2 0, 15mmol sodium oleate is dissolved in the mixture of 20mL ethanol and 60mL water, condenses and refluxes to form oleic acid gadolinium, the above-mentioned oleic acid gadolinium mixture is transferred in the separatory funnel, extracts the organic layer after adding normal hexane, and washes with pure water, in The solvent was removed on a rotary evaporator to obtain pure gadolinium oleate Gd(OA) 3 ;

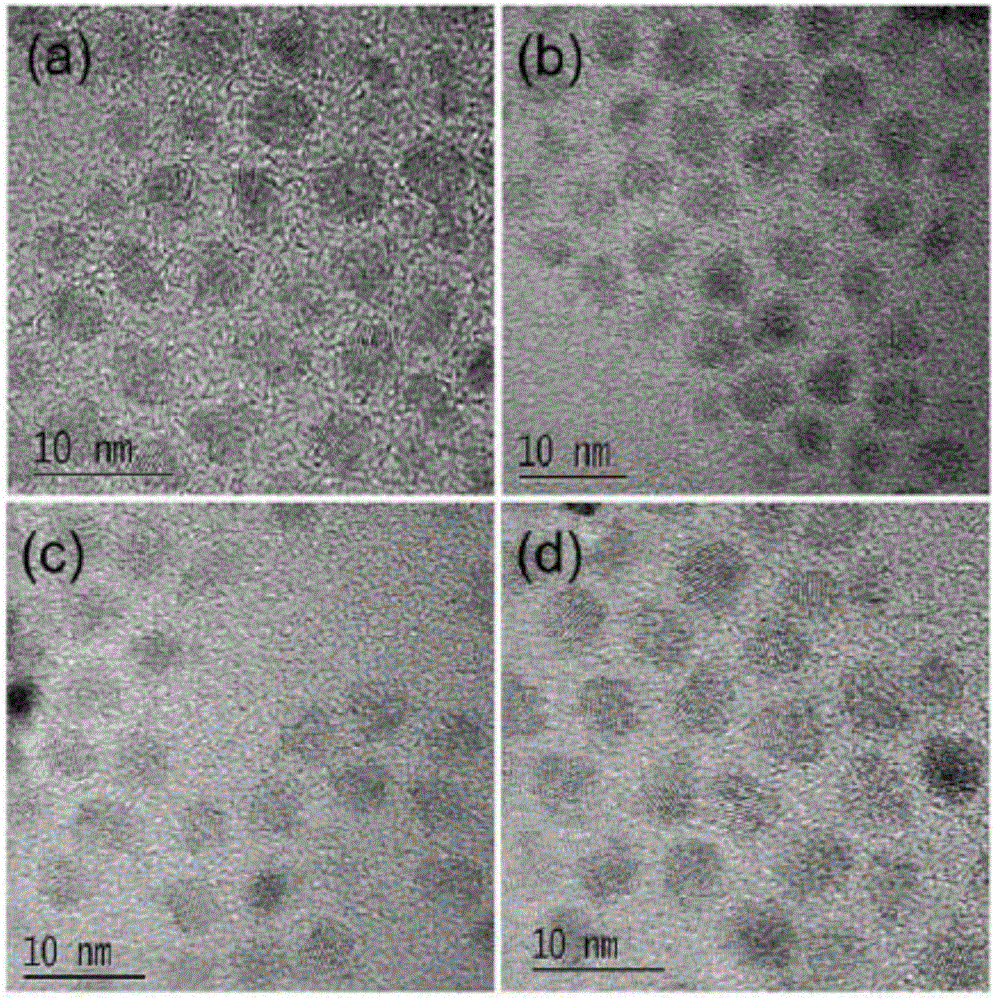

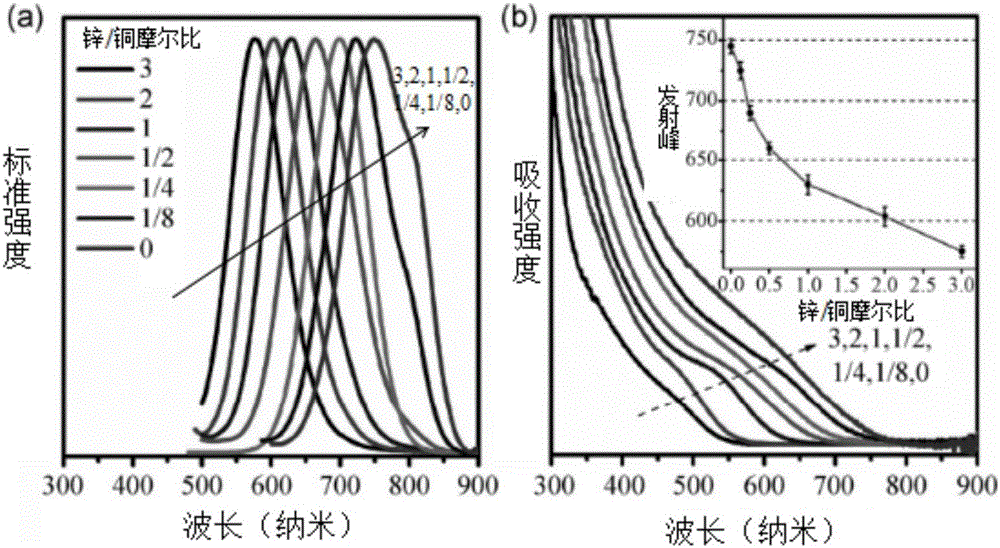

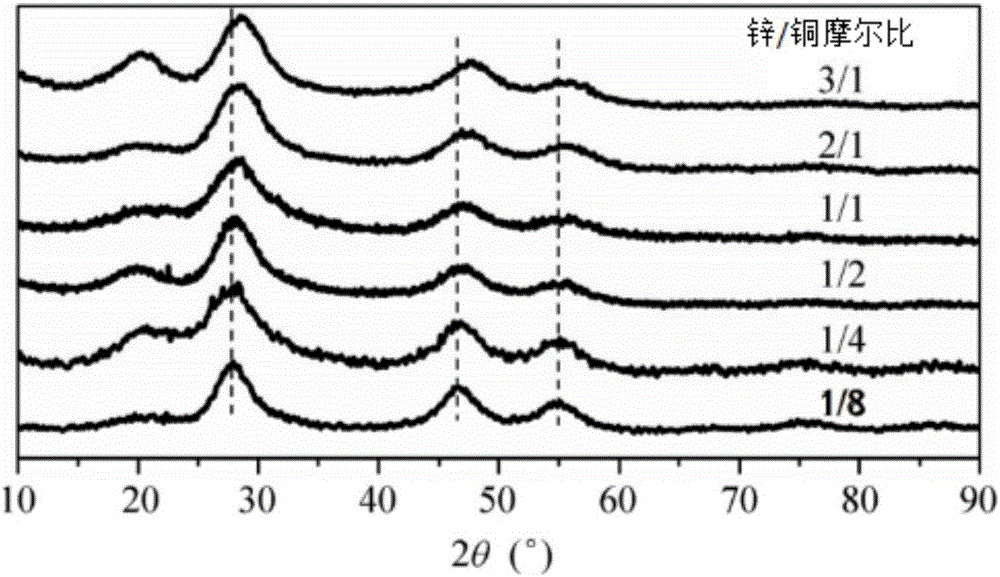

[0041] 2) The above 0.4mmol gadolinium oleate Gd(OA) 3 , 0.1mmol copper oleate Cu(OA) 2 , 0.2mmol indium oleate In(OA) 3 , 0.1mmol zinc oleate Zn(OA) 2 Add oleic acid (OA) and octadecene (ODE) into a mixed solvent (volume ratio OA: ODE = 1:20), vacuumize for 30 minutes and heat to 120°C under the protection of argon. After the solution is clarified, inject 1 mL of double p-Chlorophenyltrichloroethane (DDT), the solution turns bright yellow, quickly inject the 0.3mmol sulfur powder mixture prepared in advance (the sulfur po...

Embodiment 2

[0045] 1) 5mmol gadolinium chloride GdCl 3 .6H 2 0, 15mmol sodium oleate is dissolved in the mixture of 20mL ethanol and 40mL water, condenses and refluxes to form oleic acid gadolinium, transfers the above-mentioned oleic acid gadolinium mixture in the separatory funnel, extracts the organic layer after adding normal hexane, and washes with pure water, in The solvent was removed on a rotary evaporator to obtain pure gadolinium oleate Gd(OA) 3 ;

[0046] 2) The above 0.2mmol gadolinium oleate Gd(OA) 3 , 0.1mmol copper oleate Cu(OA) 2 , 0.2mmol indium oleate In(OA) 3 , 0.2mmol zinc oleate Zn(OA) 2 Add it into a mixed solvent of oleic acid (OA) and octadecene (ODE) (volume ratio: OA: ODE = 1:15), vacuumize for 30 minutes and heat to 120°C under the protection of argon. After the solution is clarified, inject 1 mL of double p-Chlorophenyltrichloroethane (DDT), the solution turns bright yellow, quickly inject the 0.3mmol sulfur powder mixture prepared in advance (the sulfur ...

Embodiment 3

[0050] 1) 5mmol gadolinium chloride GdCl 3 .6H 2 0, 15mmol sodium oleate is dissolved in the mixture of 20mL ethanol and 50mL water, condenses and refluxes to form oleic acid gadolinium, transfers the above-mentioned oleic acid gadolinium mixture in the separatory funnel, extracts the organic layer after adding normal hexane, and washes with pure water, in The solvent was removed on a rotary evaporator to obtain pure gadolinium oleate Gd(OA) 3 ;

[0051] 2) The above 0.6mmol gadolinium oleate Gd(OA) 3 , 0.1mmol copper oleate Cu(OA) 2 , 0.2mmol indium oleate In(OA) 3 , 0.3mmol zinc oleate Zn(OA) 2 Add it into a mixed solvent of oleic acid (OA) and octadecene (ODE) (volume ratio: OA: ODE = 1:10), vacuumize for 30 minutes and heat to 120°C under the protection of argon. After the solution is clarified, inject 1 mL of double p-Chlorophenyltrichloroethane (DDT), the solution turns bright yellow, quickly inject the 0.3mmol sulfur powder mixture prepared in advance (the sulfur ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com