Separating and exploiting method and system for processing carbonate mineral substance containing heavy oil resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

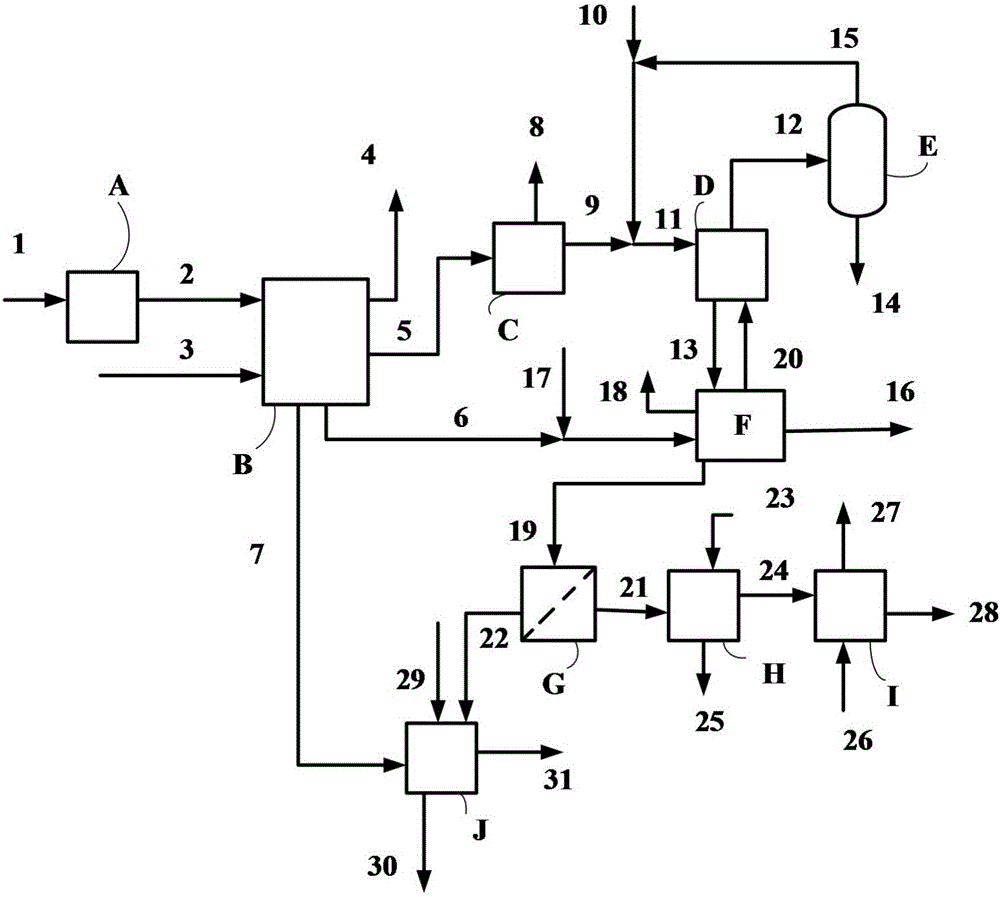

[0058] A separate mining method and system for processing heavy oil resources containing carbonate minerals, the operation steps are as follows:

[0059] (1) 15kg of oil sand (carbonate content 42%, maximum particle size 0.5cm) pulverized by pulverizer A is sent to mixing-reactor B and hydrobromic acid with a pH of 1 according to the solid-to-liquid ratio of 1:30 (mass ratio) were mixed thoroughly at room temperature and reacted for 1 hour.

[0060] (2) After the obtained asphalt foam is degassed by C, 0.5 times the mass of heptane is added to carry out solid-liquid separation (first-order sedimentation and first-order centrifugation D), and the moisture content in the upper oil phase clear liquid obtained after separation is less than 3.5%, and the solid content is less than 1.5% %, into E for separation and recovery of solvent, while obtaining asphalt oil product 14, the asphalt oil recovery rate is 79.3%, and the asphaltene content in the asphalt oil is less than 10%.

[0...

Embodiment 2

[0066] A separate mining method and system for processing heavy oil resources containing carbonate minerals, the operation steps are as follows:

[0067] ⑴ 15kg of oil sand (carbonate content 61%, maximum particle size 5cm) pulverized by pulverizer A is sent to mixing-reactor B with hydrobromic acid with a concentration of 2 mol / liter according to the solid-to-liquid ratio of 1:3 (Mass ratio) Mix well at room temperature and react for 120 minutes.

[0068] (2) After the degassing operation of the obtained bitumen foam, 5 times the mass of heptane is added to carry out solid-liquid separation (first-stage sedimentation and third-stage centrifugation D). %, into E for separation and recovery of the solvent, while obtaining asphalt oil product 14, the asphalt oil recovery rate is 85.2%, and the asphaltene content in the asphalt oil is less than 5%.

[0069] (3) The emulsion and solid precipitate obtained from the solid-liquid separation device D are sent to the pickling reaction...

Embodiment 3

[0074] A separate mining method and system for processing heavy oil resources containing carbonate minerals, the operation steps are as follows:

[0075] (1) 15kg of oil sludge pulverized by pulverizer A (carbonate content 56%, maximum particle size 1.5cm) is sent to mixing-reactor B with formic acid with a concentration of 3 mol / liter according to the solid-liquid ratio of 1:3 ( mass ratio) were fully mixed at room temperature, and reacted for 120 minutes.

[0076] (2) After the obtained asphalt foam is degassed by C, 3 times the mass of pentane is added to carry out solid-liquid separation (two-stage sedimentation and three-stage suspension D). 1.5%, enter E for separation, solvent recovery, and simultaneously obtain asphalt oil product 14, the asphalt oil recovery rate is 82.5%, and the asphaltene content in the asphalt oil is less than 3.5%.

[0077] (3) The emulsion and solid precipitate obtained from the solid-liquid separation device D are sent to the pickling reaction d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com