Anion-impregnated integrated paper for ecological board veneer

A negative ion and ecological board technology, applied in the direction of synthetic resin layered products, paper/cardboard layered products, lamination, etc., can solve the difficult to meet the needs of high-quality environmental protection products, high formaldehyde emission of finished boards, large amount of adhesives, etc. problems, to achieve the effect of benefiting human health, good cushioning and covering performance, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

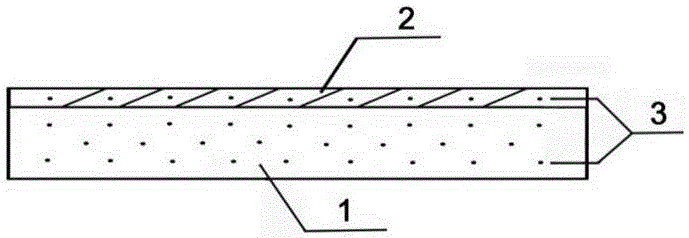

[0029] The fiber layer 1 is selected as a 0.5 mm thick polypropylene fiber layer.

[0030] Decorative paper 2 is selected as printing paper.

[0031] Anion material 3 is selected as 1000 mesh tourmaline anion powder.

[0032] A kind of negative ion impregnated integrated paper for ecological board decoration of this embodiment, the specific production process steps are as follows:

[0033] A. The fiber layer 1 and the decorative paper 2 are simultaneously impregnated and rolled together in the first dipping pool, and the dipping amount is 90% of the mass fraction of the fiber layer; the adhesive in the first dipping pool is selected as urea-formaldehyde Resin-modified adhesive, mixed into negative ion material 3, release agent MS-N1 and penetrating agent HX-8746 evenly after stirring, wherein the amount of negative ion material 3 is 15% of the adhesive mass fraction, and the amount of release agent MS-N1 is the adhesive mass fraction The amount of penetrant HX-8746 is 0.2% o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com