Method for comprehensively utilizing titanium chloride residues and filter liquid thereof in chlorination-process technologies for titanium dioxide powder

A technology of titanium dioxide and titanium chloride, applied in the direction of alkali metal chloride, alkali metal halide purification, cement production, etc., can solve the problems of resource waste, large energy consumption, high processing cost, save energy, reduce pollution, The effect of simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

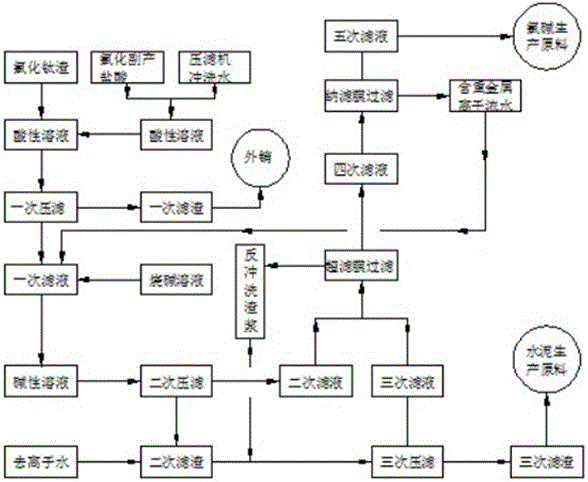

Method used

Image

Examples

Embodiment

[0027] The following is the experimental data obtained by using the method of the present invention to process titanium chloride slag and filtrate water thereof in the laboratory.

[0028] 1. 50g of titanium chloride slag, the waste residue is dissolved in 250g of acidic solution composed of 20% waste hydrochloric acid produced by the washing process of the chlorine-containing waste gas treatment system and filter press flushing water at normal temperature and pressure, and a mechanical stirrer is used for dissolution Stir for 20 minutes, the pH of the dissolved solution is ≤ 1, and a suspension is obtained, and the suspension is filtered to obtain a primary filter residue and a primary filtrate. The chloride ion content of the primary filter residue is measured to be 3.23%, and the sodium chloride concentration of the filtrate is 53.23 g / L;

[0029] 2. Add the 20% waste alkali solution produced in the production process of the chlor-alkali production system to the primary filt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com