Method for preparing fluorescent carbon nanodots through one-step hydrothermal carbonization by taking kelp as carbon source

A technology of carbon nano-dots and hydrothermal carbonization, applied in chemical instruments and methods, nanotechnology, nano-optics, etc., to achieve the effect of simple preparation method, strong practicability, and easy promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

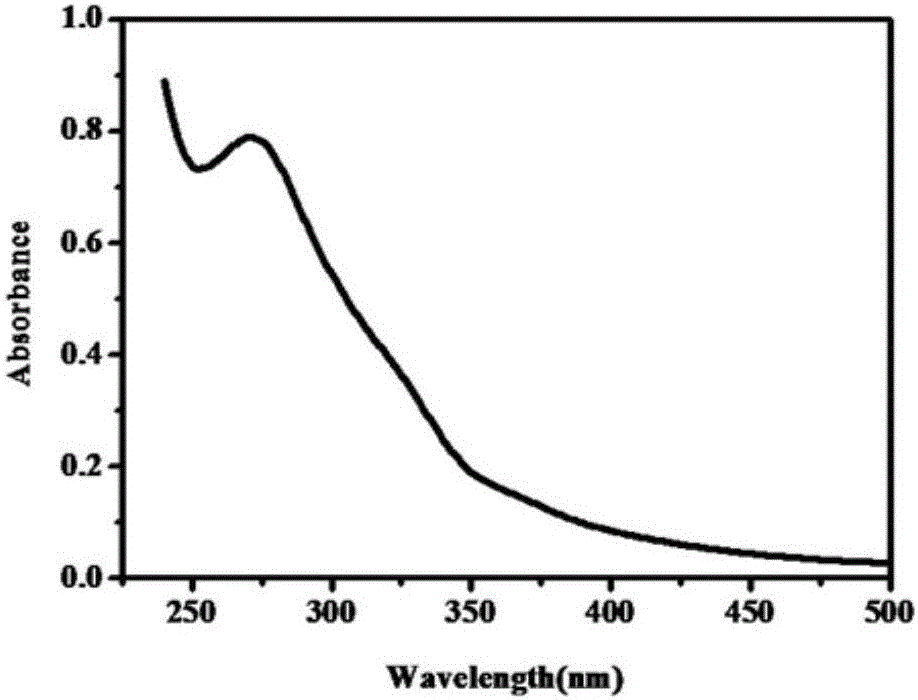

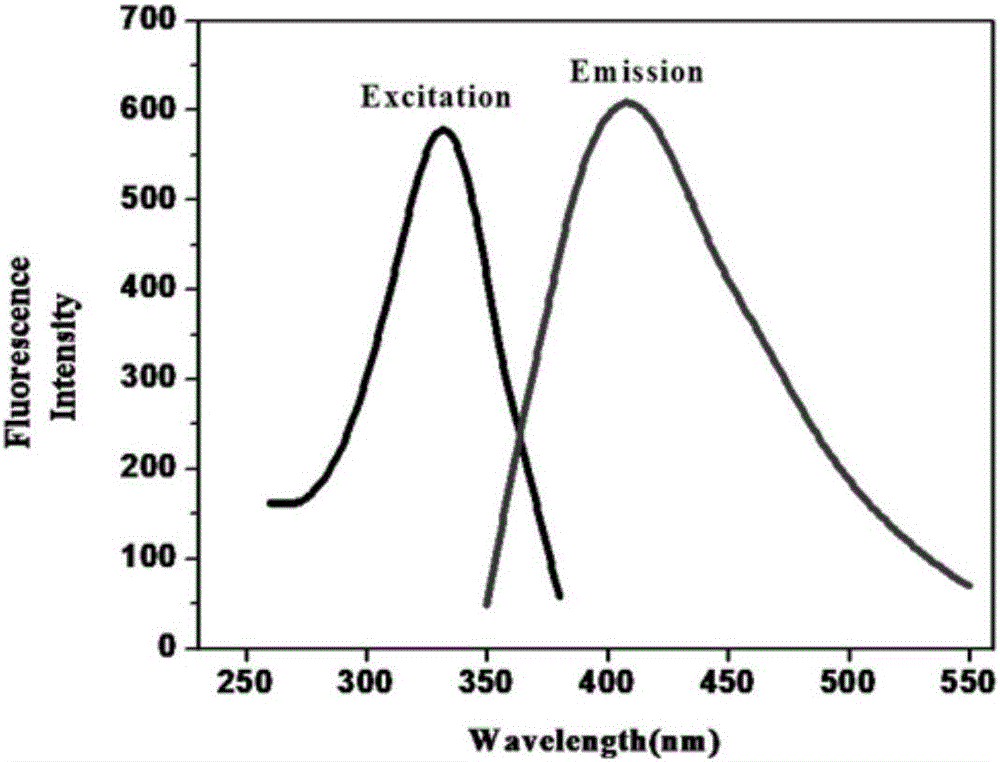

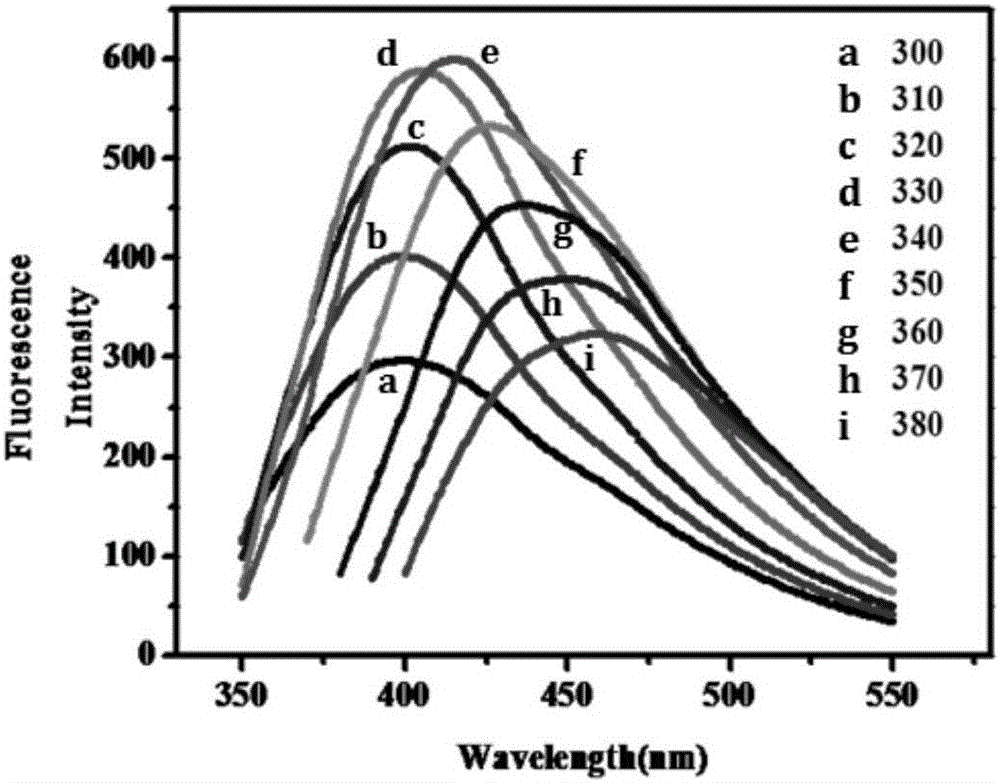

[0046]Use giant algae as carbon source to prepare fluorescent carbon nanodots by one-step hydrothermal carbonization. The detailed preparation steps of this method are as follows: 1) Wash 500g of fresh macroalgae purchased with water, cut into several pieces and put them in a tray, and put them in an oven Dry at 50°C, and after drying, crush it into powder with a pulverizer. The powder passes through a sieve with a hole size of 80 mesh to obtain a fine and uniform dried macroalgae powder; 2) Weigh 1g of macroalgae dry powder into a beaker, add 2mL Ethanol, stir evenly with a glass rod to obtain a paste; 3) Transfer the paste into a high-pressure reactor, react at 160°C for 6 hours, and obtain a dark brown product, add the product to ethanol, stir well, and then carry out suction filtration Twice, the filtrate was subjected to rotary evaporation at 60° C. to remove the solvent, centrifuged at 10,000 rpm for 15 minutes to obtain a precipitate, and the precipitate was freeze-dried...

Embodiment 2

[0049] The detailed preparation steps are as follows: 1) Wash 500g of fresh macroalgae purchased with water, cut them into several pieces and place them on a tray, put them in an oven and dry them at 60°C, and after drying, use a pulverizer to crush them into powder. Pass through a sieve with a hole size of 100 mesh to obtain fine and uniform macroalgae dry powder; 2) Weigh 2 g of macroalgae dry powder into a beaker, add 5 mL of absolute ethanol, stir with a glass rod to obtain a paste; 3) mix the paste Transfer to a high-pressure reactor and react at 180°C for 4 hours to obtain a dark brown product. Add the product to ethanol, stir evenly, and perform suction filtration twice. Rotate the filtrate at 70°C to remove the solvent, and centrifuge at 12,000rpm A precipitate was obtained after separation for 10 minutes, and the precipitate was subjected to freeze-drying treatment to obtain a dry powder of carbon nanodots. The configuration of the carbon nanodot aqueous dispersion an...

Embodiment 3

[0051] The detailed preparation steps are as follows: 1) Wash 500g of fresh macroalgae purchased with water, cut them into several pieces and place them on a tray, put them in an oven and dry them at 70°C, and after drying, grind them into powder with a pulverizer. Pass through a sieve with a hole size of 150 mesh to obtain fine and uniform macroalgae dry powder; 2) Weigh 4g of macroalgae dry powder into a beaker, add 10mL of absolute ethanol, stir with a glass rod to obtain a paste; 3) mix the paste Transfer to a high-pressure reactor and react at 190°C for 3 hours to obtain a dark brown product. Add the product to ethanol, stir evenly, and perform suction filtration twice. Rotate the filtrate at 80°C to remove the solvent, and centrifuge at 14,000rpm A precipitate was obtained after separation for 10 minutes, and the precipitate was subjected to freeze-drying treatment to obtain a dry powder of carbon nanodots. The configuration of the carbon nanodot aqueous dispersion and i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com