Method for producing high fructose syrup by immobilized glucose isomerase

A technology of glucose isomerase and high fructose syrup, applied in isomerase, biochemical equipment and methods, immobilized on or in inorganic carriers, etc., can solve the problems of difficult industrial application, cumbersome, low yield and the like , to achieve the effect of high reuse efficiency, high enzyme load and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

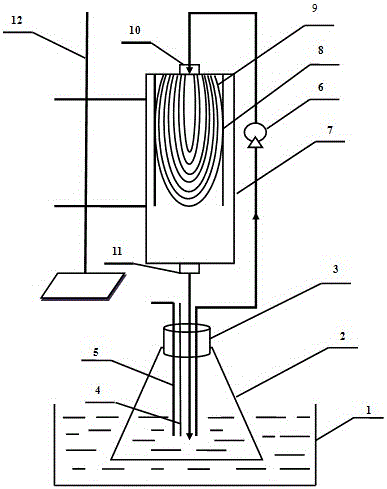

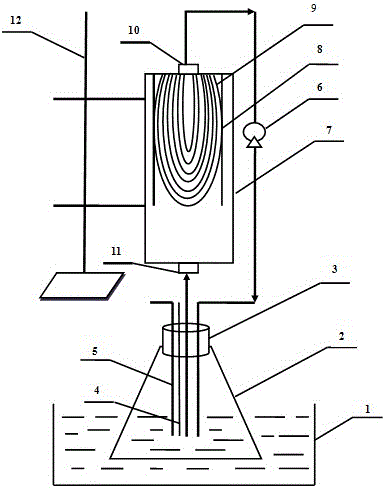

[0022] Dissolve 200 g of glucose isomerase in 1000 mL of phosphate buffer (pH=7.4), the amount of glucose isomerase in the system is 0.2 g / mL, and the glucose isomerase solution is filtered by pumping (filtering The method is filtration, gravity filtration, pressure filtration, vacuum filtration, centrifugal filtration or cross-flow filtration) through a polyvinylidene fluoride flat membrane with an asymmetric structure, and the filtration direction is from the loose side of the membrane to the dense side, and the glucose isomerization The enzyme is almost completely immobilized in the loose layer of the membrane to obtain an immobilized enzyme membrane reactor; 40% glucose solution is pumped into the immobilized enzyme membrane reactor, and the feed liquid flows back into the enzyme membrane reactor for a cyclic reaction. The reaction temperature is 50 ℃, the reaction time was 4 h; after the reaction, the fresh glucose solution was replaced, and the above reaction was restarte...

example 2

[0024] Dissolve 200 g of glucose isomerase in 1000 mL of phosphate buffer (pH=7.4), the amount of glucose isomerase in the system is 0.2 g / mL, and the glucose isomerase solution is filtered by pumping (filtering The method is filtration, gravity filtration, pressure filtration, vacuum filtration, centrifugal filtration or cross-flow filtration) through the polyacrylonitrile hollow fiber membrane with an asymmetric structure, and the filtration direction is from the loose side of the membrane to the dense side, and the glucose isomerization The enzyme is almost completely immobilized in the loose layer of the membrane to obtain an immobilized enzyme membrane reactor; then the membrane is put into the membrane reactor to make an immobilized enzyme membrane reactor; 40% glucose solution is pumped into the immobilized enzyme membrane to react The feed liquid flowed back into the enzyme membrane reactor for a circular reaction, the reaction temperature was 60°C, and the reaction tim...

example 3

[0026] Dissolve 500 g of glucose isomerase in 1000 mL of phosphate buffer (pH=7.4), the amount of glucose isomerase in the system is 0.5 g / mL, and the glucose isomerase solution is filtered by pumping (filtering The method is filtration, gravity filtration, pressure filtration, vacuum filtration, centrifugal filtration or cross-flow filtration) through a polysulfone flat membrane with an asymmetric structure, the filtration direction is from the loose side of the membrane to the dense side, and the membrane converts glucose Almost completely immobilized in the loose layer of the membrane to obtain an immobilized enzyme membrane reactor; then put this membrane into the membrane reactor to make an immobilized enzyme membrane reactor; pump 50% glucose solution into the immobilized enzyme membrane reactor , the feed liquid flowed back into the enzyme membrane reactor for cyclic reaction. The reaction temperature was 60 °C and the reaction time was 5.5 h. reached 97.9%, and the imm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com