A method for smelting reduction recovery and quenching and tempering treatment of mixed slag

A technology for quenching and tempering treatment and slag melting, which is applied in recycling technology, process efficiency improvement, cement production and other directions, can solve the problems of leaching polluted environment, polluted environment, massive accumulation of steel slag, etc., and achieves the effect of high efficiency and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

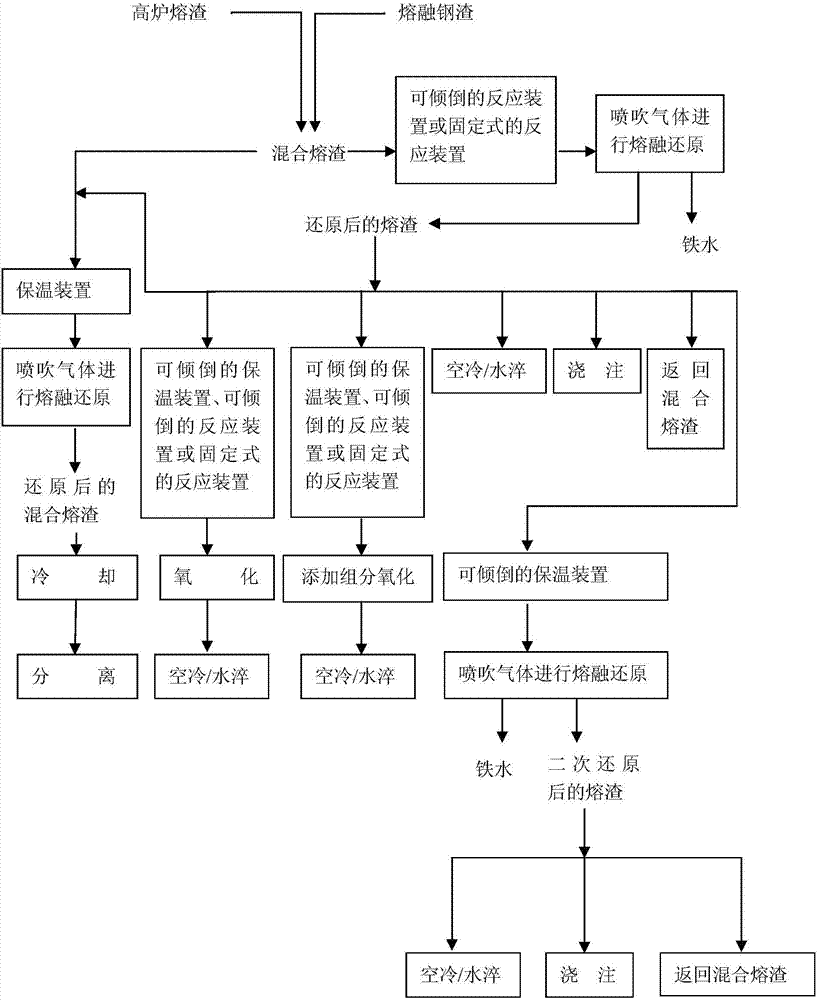

[0123] A method for smelting reduction recovery and quenching and tempering treatment of mixed slag is carried out according to the following steps:

[0124] Step 1, slag mixing

[0125] With the blast furnace slag obtained from the blast furnace slag outlet, the converter steelmaking molten steel slag obtained from the steel slag outlet, by mass ratio, blast furnace slag: converter steelmaking molten steel slag=(400: 4) kg batching, add the In the thermal insulation slag tank of graphite-dolomite composite thermal insulation refractory material, fully mix to obtain mixed slag; during the mixing process of slag, the iron oxide in the slag undergoes melting and reduction reaction, and the temperature of the slag after mixing is 1520°C. The temperature of the slag is in the range of 1350-1550°C;

[0126] Step 2, blowing gas for smelting reduction:

[0127] (1) Gas injection: Inject preheated oxygen into the mixed slag for 10 minutes, wherein the preheating temperature of oxyge...

Embodiment 2

[0142] A method for smelting reduction recovery and quenching and tempering treatment of mixed slag is carried out according to the following steps:

[0143] Step 1, slag mixing

[0144] The blast furnace slag obtained from the blast furnace slag outlet, the electric furnace steelmaking fused oxidized steel slag obtained from the steel slag outlet, by mass ratio, blast furnace slag: electric furnace steelmaking fused oxidized steel slag=(400:10) kg batching, add In the thermal insulation pit with carbon-magnesium composite thermal insulation refractory material, fully mix to obtain mixed slag; during the mixing process of slag, the iron oxide in the slag undergoes melting and reduction reaction, and the temperature of the slag after mixing is 1535°C , the temperature of the mixed slag is in the range of 1350-1550°C;

[0145] Step 2, blowing gas for smelting reduction:

[0146] (1) Gas injection: Inject preheated oxygen into the mixed slag for 8 minutes, wherein the preheatin...

Embodiment 3

[0160] A method for smelting reduction recovery and quenching and tempering treatment of mixed slag is carried out according to the following steps:

[0161] Step 1, slag mixing

[0162] With the blast furnace slag obtained from the blast furnace slag outlet, the converter steelmaking molten steel slag obtained from the steel slag outlet, by mass ratio, blast furnace slag: converter steelmaking molten steel slag=(400:40) kg batching, add the In the thermal insulation pit of graphite-spinel composite thermal insulation refractory material, the mixed slag is obtained by fully mixing; during the mixing process of the slag, the iron oxide in the slag undergoes melting and reduction reaction, and the temperature of the slag after mixing is 1565°C. The temperature of the mixed slag exceeds the set temperature by 1350-1550°C. After adding 10kg of blast furnace slag to the heat preservation pit, the temperature of the mixed slag is 1546°C;

[0163] Step 2, blowing gas for smelting re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com