Nano oxide based on metal-organic frameworks (MOFs) and preparation method thereof

A nano-oxide, organic framework technology, applied in nanotechnology, hybrid/electric double-layer capacitor manufacturing, hybrid capacitor electrodes, etc., can solve problems such as limiting the large-scale application of nano-oxides, and achieve appearance preservation and good performance. The effect of performance, thickness reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

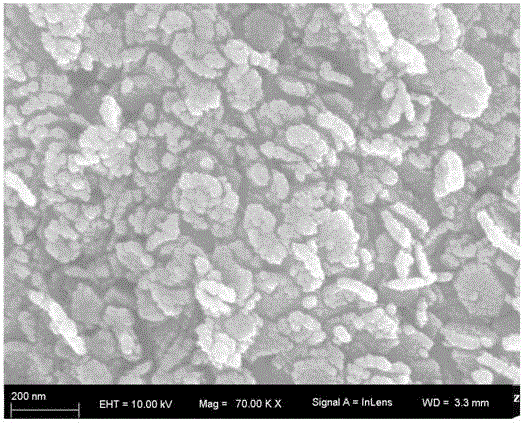

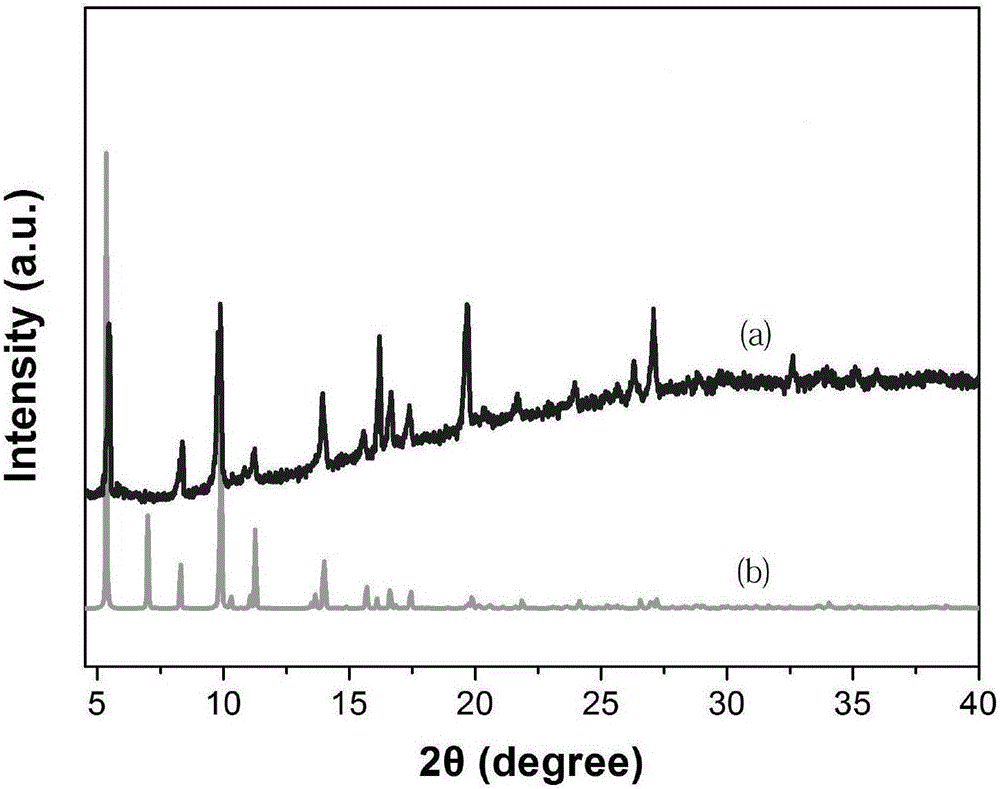

[0035] (1) Preparation of UPC-9 metal-organic framework: Weigh cobalt nitrate and 2,3,5,6-tetramethyl-1,4-diisophthalic acid (TMBDI) according to the mass ratio of 1:0.6 In a polytetrafluoroethylene reactor, DMA:H 2 O=1:15ml, shake to mix evenly. Seal the reaction kettle, react at 120°C for 72 hours, and then cool to room temperature; filter the above reaction solution, wash the precipitate with mother liquor, and dry at room temperature to obtain the crystalline material to be prepared for the next test and experiment.

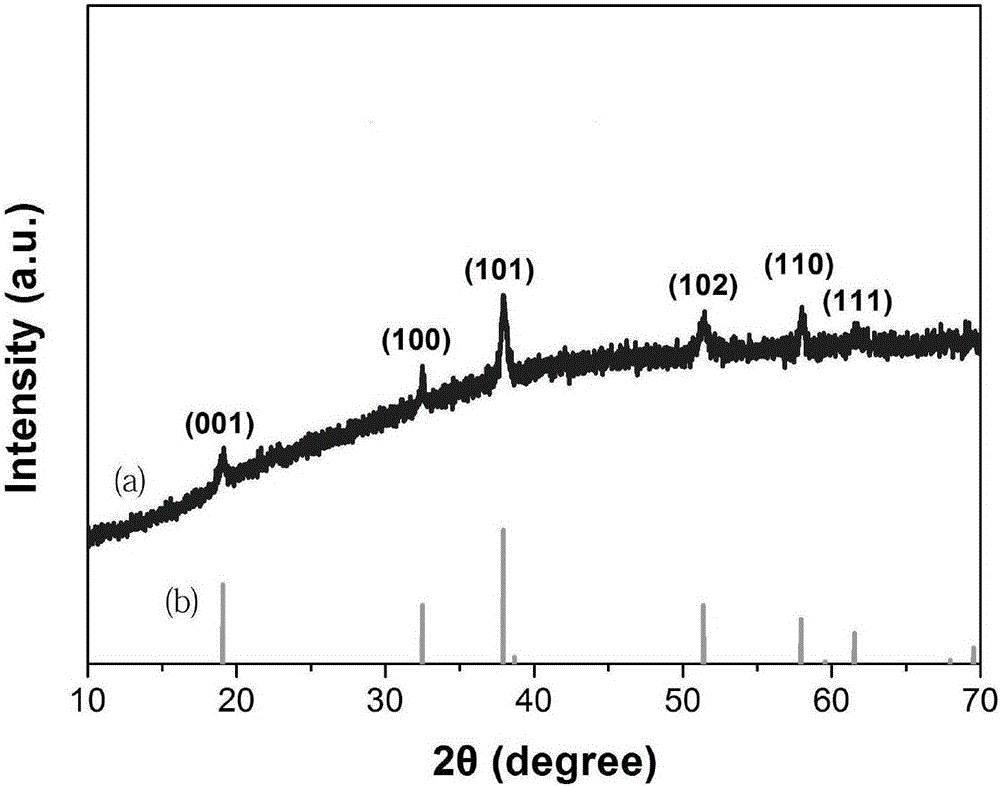

[0036] (2) Preparation of Cobalt Tetroxide Nanosheets: Weigh 100mg of UPC-9 and place it in a 10ml sample tube, then add 8ml of 1M KOH solution, shake to make it evenly dispersed. After soaking for 30 minutes, pour the supernatant into the beaker, then add 8ml of the above alkali solution, and let stand for 30 minutes. Pour the supernatant into the beaker, then soak and rinse twice with deionized water and methanol repeatedly for five minutes each time, and...

Embodiment 2

[0039] (1) The preparation of UPC-9 metal-organic framework is the same as in Example 1.

[0040] (2) Preparation of Cobalt Tetroxide Nanosheets: Weigh 100mg of UPC-9 and put it in a 10ml sample tube, then add 0.1M KOH 8ml solution, shake to make it evenly dispersed. After soaking for 30 minutes, pour the supernatant into the beaker, then add 8ml of the above alkali solution, and let stand for 30 minutes. Pour the supernatant into the beaker, then soak and rinse with deionized water and methanol twice for five minutes each time, and then filter to collect the obtained pink multi-level block Co(OH) 2 , dried under vacuum at 65°C for 12h to obtain Co(OH) 2 Precursor. Will get Co(OH) 2 The precursor is under oxygen condition, at 20°C min -1 The heating rate was raised to 350°C and kept for 50 minutes to obtain ultra-thin Co 3 o 4 nanosheet structure.

[0041] (3) The preparation of the active material electrode is the same as in Example 1.

Embodiment 3

[0043] (1) The preparation of UPC-9 metal-organic framework is the same as in Example 1.

[0044] (2) Preparation of Cobalt Tetroxide Nanosheets: Weigh 100mg of UPC-9 and place it in a 10ml sample tube, then add 8ml of 0.5M KOH solution, shake to make it evenly dispersed. After soaking for 30 minutes, pour the supernatant into the beaker, then add 8ml of the above alkali solution, and let stand for 30 minutes. Pour the supernatant into the beaker, then soak and rinse with deionized water and methanol twice for five minutes each time, and then filter to collect the obtained pink multi-level block Co(OH) 2 , dried under vacuum at 65°C for 12h to obtain Co(OH) 2 Precursor. Will get Co(OH) 2 The precursor is under oxygen condition, at 20°C min -1 The heating rate was raised to 350°C and kept for 50 minutes to obtain ultra-thin Co 3 o 4 nanosheet structure.

[0045] (3) The preparation of the active material electrode is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com