Lithium ion battery composite cathode material LiNi1-x-yMxAlyO2 with core-shell structure and preparation method of lithium ion battery composite cathode material LiNi1-x-yMxAlyO2

A composite positive electrode material and lithium-ion battery technology, applied in battery electrodes, secondary batteries, structural parts, etc., can solve the problems of environmental moisture and carbon dioxide sensitivity, poor cycle stability and poor thermodynamic stability of nickel-rich positive electrode materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

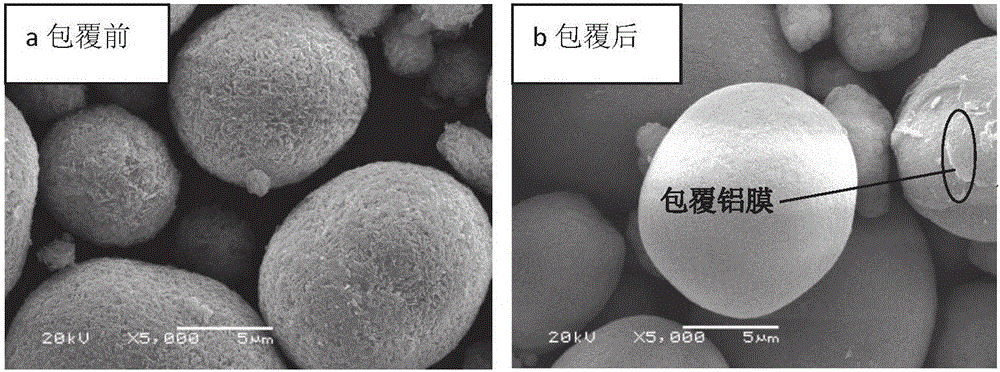

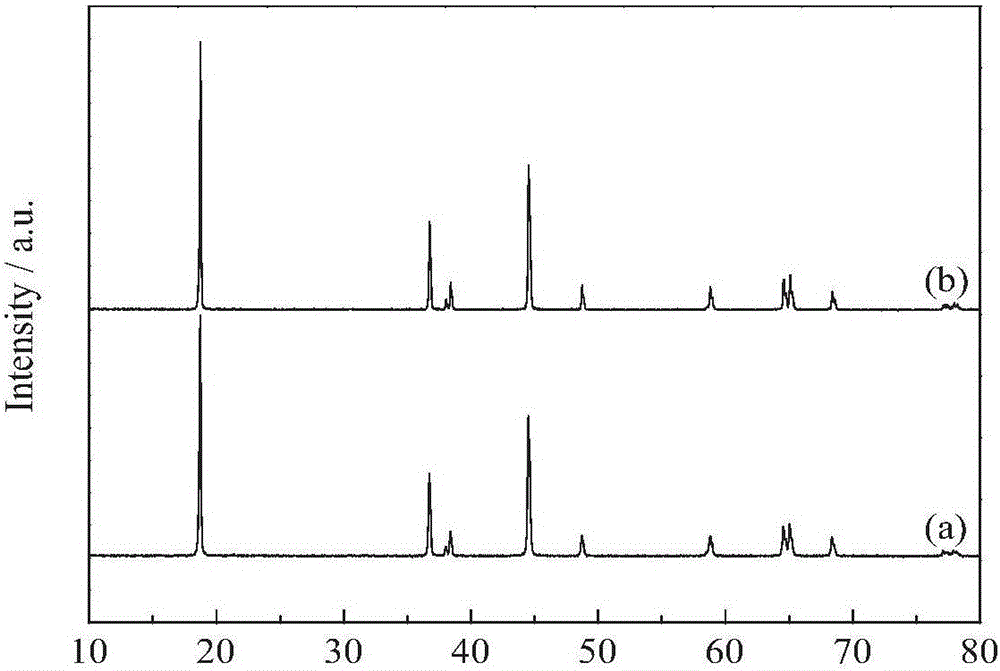

[0062] Adopt publication number to be that the method described in CN103066257A synthesizes 5Kg Ni 0.815 co 0.15 Al 0.035 (OH) 2 Precursor (NCA precursor; SEM see figure 1 part a of ). Stop the reaction when the particle size distribution D50 of the product is 11.4-11.5 microns. Filter mother liquor to obtain NCA precursor (Ni 0.815 co 0.15 Al 0.035 (OH) 2 ). Add the NCA precursor to a 50L reaction kettle, add 30Kg of deionized water, stir for 30min at a stirring speed of 3m / s, and use sodium hydroxide to control pH=11.50, add 1.09L of 0.5mol / L sodium metaaluminate solution , and slowly add 0.2mol / L dilute sulfuric acid solution at a flow rate of 5ml / min until 9.0≤pH≤10 in the reactor; then after aging the acid-reacted slurry for 30min, filter the mother liquor, and use 60℃, 10 % sodium chloride solution for 30 minutes, the slurry was washed, filtered and dried to obtain Ni 0.815 co 0.15 Al 0.035 (OH) 2 / Al(OH) 3 (NCA precursor and Al(OH) 3 The molar ratio of c...

Embodiment 2

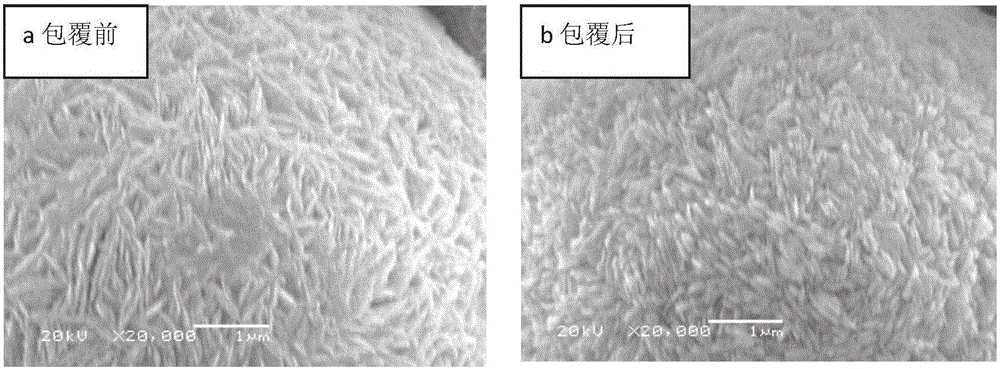

[0068] 5Kg Ni 0.9 co 0.1 (OH) 2 Precursor (SEM see image 3 Part a) was added to the 50L coated reactor. Add 30Kg of deionized water and stir for 30min at a stirring speed of 3m / s. Use sodium hydroxide to control pH = 11.50, add 2.16L of 0.5mol / L sodium metaaluminate solution, and feed CO at a flow rate of 300ml / min 2 Gas until the solution is 9.5≤pH≤10; then the acid-reacted slurry is aged for 30 minutes, the mother liquor is filtered, and the precipitate is washed with 30Kg 60°C deionized water, and the precursor is washed, filtered, and dried to obtain Ni 0.9 co 0.1 (OH) 2 / Al(OH) 3 (molar ratio is 100:2) composite precursor (SEM see image 3 Part b of ), it can be seen from the SEM image that the surface morphology of the precursor before and after aluminum coating is very different, and the Al(OH) 3 Distributed on the surface of spherical particles, a uniform aluminum hydroxide film is formed. Then Ni 0.9 co 0.1 (OH) 2 / 0.02Al(OH) 3 After being uniformly mix...

Embodiment 3

[0074] Take 5Kg Ni 0.8 co 0.2 (OH) 2 The precursor was added to the 50L coating reactor. Add 30Kg of deionized water and stir for 30min at a stirring speed of 4m / s. Use sodium hydroxide to control pH = 11.50, add 2.16L of 0.5mol / L sodium metaaluminate solution, and feed CO at a flow rate of 400ml / min 2 Gas until the solution is 9.5≤pH≤10; then, after aging the acidified slurry for 30 minutes, filter the mother liquor, and wash it with 60°C, 10% sodium chloride solution for 30 minutes, and the slurry is washed, filtered and dried to obtain Ni 0.80 co 0.20 (OH) 2 / Al(OH) 3 (molar ratio of 100:2) precursor. Then Ni 0.80 co 0.20 (OH) 2 / 0.02Al(OH) 3 After being uniformly mixed with the metered ratio of lithium hydroxide (Li / (Ni+M+Al) molar design ratio is 1), it was placed in an oxygen atmosphere furnace and calcined at 750°C for 12 hours and cooled to room temperature to obtain LiNi 0.784co 0.196 Al 0.02 o 2 Composite cathode material (LiAlO 2 Coated composite cat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com