Process for producing activated wheat bran dietary fibers

A technology of wheat bran dietary fiber and production process, which is applied in the field of food processing to achieve the effect of increasing fiber content, improving taste and avoiding environmental pollution problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

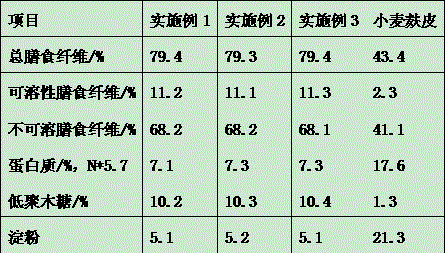

Examples

Embodiment 1

[0021] The production process of the activated wheat bran dietary fiber provided by the present embodiment comprises the following steps:

[0022] (1) Cleaning: Wash the wheat bran with water for 3 times, then dry it to remove impurities such as floating dust in the raw bran, and pre-dry it until the water content is 30%.

[0023] (2) Fractionation and separation by breaking the wall: The protein and starch adhering to the surface of the bran are effectively peeled off by physical wall breaking machine, and the peeled protein and starch are separated through the fractionation and separation system by using the different specific gravity, so that The crude fiber content is increased, and the crude fiber content reaches 60%.

[0024] (3) Enzymolysis: Enzymolyze the crude fiber obtained by fractionation, add 12 parts by weight of monoglyceride stearate and 15 parts by weight of malic acid to 100 parts by weight of the crude fiber, and add 0.2 parts of For high temperature resist...

Embodiment 2

[0032] The production process of the activated wheat bran dietary fiber provided by the present embodiment comprises the following steps:

[0033] (1) Cleaning: Wash the wheat bran once with clean water, then dry it to remove impurities such as floating dust in the raw bran, and pre-dry it until the water content is 30%.

[0034] (2) Fractionation and separation by breaking the wall: The protein and starch adhering to the surface of the bran are effectively peeled off by physical wall breaking machine, and the peeled protein and starch are separated through the fractionation and separation system by using the different specific gravity, so that The crude fiber content is increased, and the crude fiber content reaches 60%.

[0035] (3) Enzymolysis: Enzymolyze the crude fiber obtained by fractionation, add 8 parts by weight of monoglyceride stearate and 10 parts by weight of malic acid to 100 parts by weight of the crude fiber, and add 0.01 part of For high temperature resistan...

Embodiment 3

[0043] The production process of the activated wheat bran dietary fiber provided by the present embodiment comprises the following steps:

[0044] (1) Cleaning: Wash the wheat bran twice with water, then dry it to remove impurities such as floating dust in the raw bran, and pre-dry it until the water content is 30%.

[0045] (2) Fractionation and separation by breaking the wall: The protein and starch adhering to the surface of the bran are effectively peeled off by breaking the wall with a physical wall breaking machine, and the peeled protein and starch are separated by using the different specific gravity through the fractionation system to obtain Crude fiber, the content of crude fiber reaches 60%.

[0046] (3) Enzymolysis: Enzymolyze the crude fiber obtained by fractionation, add 10 parts by weight of monoglyceride stearate and 12 parts by weight of malic acid to 100 parts by weight of crude fiber, and add 0.1 part of For high temperature resistant α-amylase, add water t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com