Mobile integrated filter separation system device for colleting geothermal water

A filtration separation and system device technology, applied in the direction of filtration separation, separation device, fixed filter element filter, etc., can solve the problems of cost increase, large water demand, large floor space, etc., to avoid pressure loss and blockage, extend Longevity and maintenance cost reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

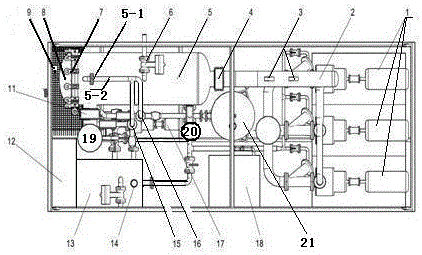

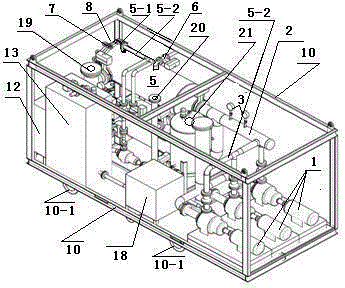

[0026] Further description of embodiment 1: First, the filter element is assembled on the inner cover head 8 of the filter 5. The head 8 is fastened to the bottom end of the filter 5 by bolts 7; the grille water tank 9 is bolted to the container under the head 8 The bottom corner; the inlet pipeline 2 is flanged to the inlet valve 4 and connected to the inlet of the filter 5, the flange connector 5-1 is welded to the bottom of the filter 5, and the automatic exhaust valve 6 is flanged to the filter 5 In the middle section of the filter 5, the inlet flange of the filter 5 is connected to the outlet valve 11 to the outlet line 18, and the bottom of the filter 5 is flanged to the sewage line 20. This is the equipment for the entire normal working process;

Embodiment 2

[0027] Embodiment 2: One end of the backwash pump 17 is threadedly connected to the filter 5 through a pipeline 5-2, and the connected pipeline 5-2 is threadedly connected to the backwash liquid inlet 15, the backwash gas inlet 16, and the inlet and outlet valves 11 respectively. ; The other end of the backwash pump 17 is threaded to the water storage tank 13 through the pipeline 5-2, and the liquid level transmitter 14 is fixedly installed on the water tank 13 with bolts; the electric control cabinet 12, the water storage tank 13 and the air compressor 18 bolts It is fixedly installed on the base of the container frame 10; the gas storage tank 21 is fixedly installed in the middle of the base of the container frame 10 by bolts, and is threadedly connected with the back blow air inlet 16 by the pipeline 5-2; this is a backwash and back blow work process equipment .

[0028] There are two main functions for installing two filters in the system. One is to ensure online backwashing....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com