Adsorbent for industrial wastewater treatment and preparation method thereof

A technology of industrial wastewater and adsorbents, which is applied in water/sewage treatment, adsorption water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of expensive adsorbents, difficult regeneration, and low adsorption efficiency, and achieve Effects of improving alternating performance and adsorption performance, improving stability and strength, and increasing adsorption activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A preparation method for an adsorbent for industrial wastewater treatment, comprising the steps of:

[0024] (1) Preparation of modified composite powder: Take 15 parts of kaolin and 20 parts of sepiolite and disperse in 100 parts of toluene, and ultrasonically shake at room temperature for 1 hour, then drop 6 parts of quaternary ammonium salt tetramer Surfactant and 4 parts of cetyltrimethylammonium bromide carry out the modification reaction, the modification reaction is carried out under the water bath, the reaction temperature is 75 ℃, the reaction time is 4 hours, after the modification is completed, filter , washing, drying, and crushing to obtain a modified composite powder;

[0025] (2) Preparation of composite cross-linked adsorbent: Add the modified composite powder obtained in step (1) to 10 parts of polyvinyl alcohol and 6 parts of chitosan, mix and stir evenly, and then add the above mixture to saturated boric acid Carry out immobilized cross-linking in th...

Embodiment 2

[0028] A preparation method for an adsorbent for industrial wastewater treatment, comprising the steps of:

[0029] (1) Preparation of modified composite powder: Take 30 parts of kaolin and 40 parts of sepiolite and disperse in 180 parts of N,N-dimethylformamide, and ultrasonically shake at room temperature for 2 hours, then drop 12 parts of quaternary ammonium salt tetrameric surfactants and 8 parts of cetyltrimethylammonium bromide carry out modification reaction, and described modification reaction is carried out under water bath, and reaction temperature is 85 ℃, and reaction time is 8 After modification, filter, wash, dry, and pulverize to obtain a modified composite powder;

[0030] (2) Preparation of composite cross-linked adsorbent: Add the modified composite powder obtained in step (1) to 15 parts of polyvinyl alcohol and 12 parts of chitosan, mix and stir evenly, and then add the above mixture to saturated boric acid Carry out immobilized cross-linking in the soluti...

Embodiment 3

[0033] A preparation method for an adsorbent for industrial wastewater treatment, comprising the steps of:

[0034] (1) Preparation of modified composite powder: Take 25 parts of kaolin and 30 parts of sepiolite and disperse them in 150. - one or more of dimethylacetamide and tetrahydrofuran.

[0035] The industrial wastewater is one or more of wastewater containing heavy metal ions, printing and dyeing wastewater, and petrochemical wastewater.

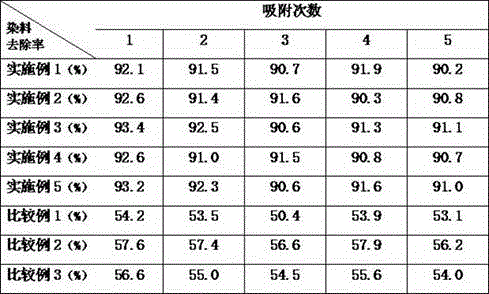

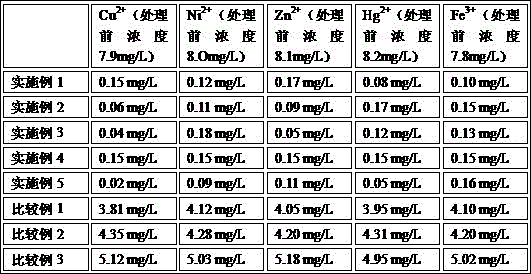

[0036]The technical effects of the present invention are: (1) The adsorbent of the present invention is composed of kaolin and sepiolite as the basic adsorbent raw material, fully combining the characteristics of the two with high specific surface agent, complex pore structure and excellent adsorption sites, extremely Greatly improved the adsorption activity of a single raw material as an adsorbent; in addition, the present invention adopts quaternary ammonium salt tetrameric surfactant and cetyltrimethylammonium bromide to first mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com