High-slump-retaining polycarboxylic acid composite water reducer and preparation method thereof

A composite water reducing agent and polycarboxylic acid technology, applied in the field of building material additives, can solve the problems of aggravating the adaptability of concrete raw materials, affecting the dispersibility of the polycarboxylic acid water reducing agent, increasing the consumption of concrete raw materials, etc. Chemical synthesis cost, easy operation, reducing the effect of ineffective adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

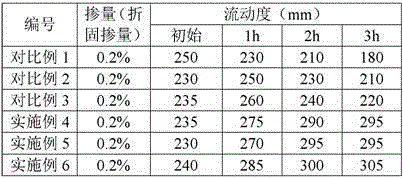

Examples

Embodiment 1

[0035] At room temperature, in a four-neck flask with stirring, put 360 parts of prenol polyoxyethylene ether (2400) and 180 parts of deionized water, after stirring and dissolving evenly, add 3.6 parts of hydrogen peroxide (30%, based on hydrogen peroxide content ), after stirring for 10 minutes, start to drop A and B solutions at the same time. Solution A is a solution composed of 0.72 parts of vitamin C, 1.6 parts of mercaptopropionic acid and 120 parts of deionized water. Solution B is a solution composed of 41 parts of acrylic acid and 60 parts of deionized water. The time for adding solution A is 2.5 hours, and the time for adding solution B is 2 hours. After A and B solutions are added dropwise, continue the aging reaction for 1 hour, then add sodium hydroxide solution (40%) to neutralize to a pH of 5-7, and then add water to adjust the solid content to 40%, to obtain a polycarboxylate superplasticizer .

Embodiment 2

[0037] At room temperature, put 400 parts of prenol polyoxyethylene ether (2400) and 200 parts of deionized water into a four-neck flask with stirring, stir and dissolve evenly, then add 2.0 parts of ammonium persulfate, and start stirring at the same time after 10 minutes Add solution A and B dropwise. Solution A is a solution composed of 0.8 parts of saffron, 1.8 parts of thioglycolic acid and 120 parts of deionized water. Solution B is a solution composed of 36 parts of acrylic acid, 18 parts of methacrylic acid and 65 parts of deionized water. The time for adding solution A is 2.5 hours, and the time for adding solution B is 2 hours. After the A and B solutions are added dropwise, continue the aging reaction for 1 hour, then add sodium hydroxide solution (40%) to neutralize to a pH of 5-7, and then add water to adjust the solid content to obtain a polycarboxylate superplasticizer.

Embodiment 3

[0039]At room temperature, in a four-neck flask with stirring, put 400 parts of prenol polyoxyethylene ether (2400) and 200 parts of deionized water, after stirring and dissolving evenly, add 4.0 parts of hydrogen peroxide (30%, based on hydrogen peroxide content ), after stirring for 10 minutes, start to drop A and B solutions at the same time. Solution A is a solution composed of 1.0 parts of vitamin C, 2.0 parts of sodium methacrylate and 120 parts of deionized water. Material B is a solution composed of 35 parts of acrylic acid, 20 parts of fumaric acid and 65 parts of deionized water. The time for adding solution A is 2.5 hours, and the time for adding solution B is 2 hours. After the A and B solutions are added dropwise, continue the aging reaction for 1 hour, then add sodium hydroxide solution (40%) to neutralize to a pH of 5-7, and then add water to adjust the solid content to obtain a polycarboxylate superplasticizer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com