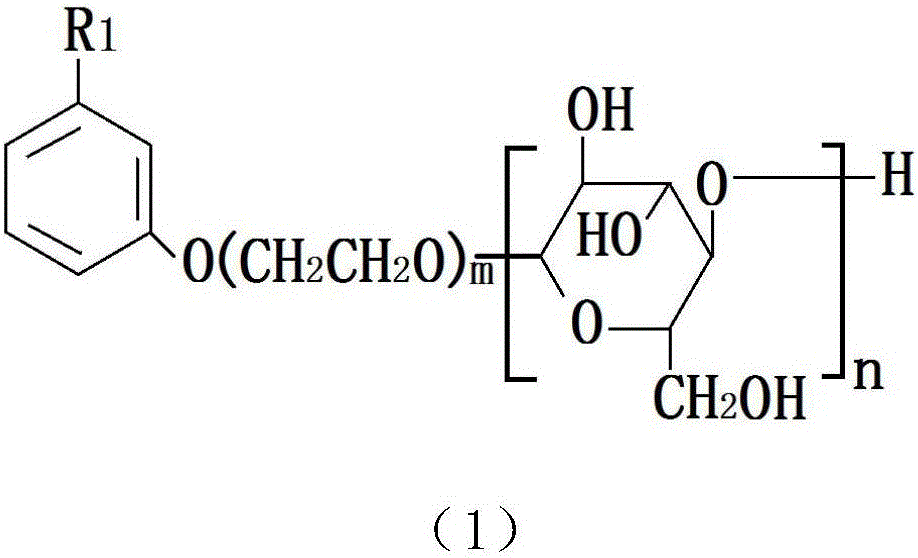

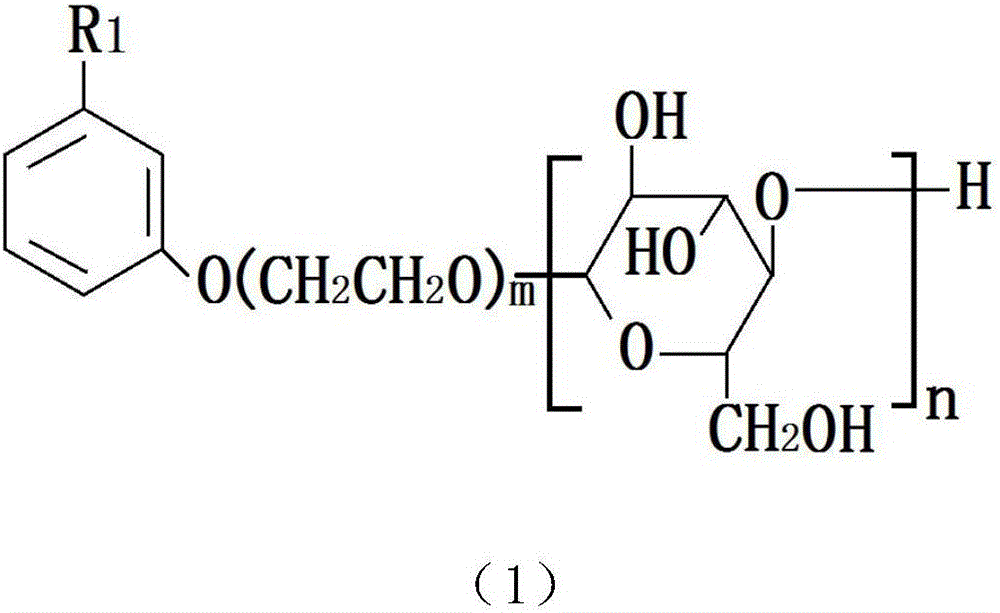

Pentadecyl (pentadecenyl) resorcinol polyoxyethylene ether glucoside and its preparation method and use

A technology of m-phenol polyoxyethylene ether-based glucoside and m-phenol polyoxyethylene ether, which is applied in the field of pentadecyl m-phenol polyoxyethylene ether-based glucoside and its preparation, and can solve unmentioned problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Take 300g of refined cardanol and put it into a high-pressure reactor, add 0.6g of 50% potassium hydroxide solution, and carry out nitrogen replacement. ℃~130℃ for dehydration. After the dehydration is completed, raise the temperature to 135°C-160°C, add 44g of ethylene oxide to carry out the epoxidation reaction, control the temperature of the addition reaction at 130°C-190°C, and control the pressure below 0.3MPa. After the addition reaction is completed, Lower the temperature to 65°C-75°C, add 0.33g of acetic acid to neutralize until the pH value reaches 5.0-8.0, and obtain cardanol polyoxyethylene ether. A certain amount of pentadecyl (en) base metaphenol (cardanol) polyoxyethylene ether, glucose 180g, solid acid TiO 2 / SO 2 -4 and TiO 2 -ZrO 2 / SO 2 -4 Put 3.44g of mixed catalyst into the reactor, stir evenly, reduce the pressure to 4kPa, rapidly raise the temperature to 90-120°C, keep the temperature for 2.5-4.0h, and continuously pump out the generated water...

Embodiment 2

[0034]Take 300g of refined cardanol and put it into a high-pressure reactor, add 0.6g of 50% potassium hydroxide solution, and carry out nitrogen replacement. ℃~130℃ for dehydration. After the dehydration is completed, raise the temperature to 135°C-160°C, add 88g of ethylene oxide to carry out the epoxidation reaction, control the temperature of the addition reaction at 130°C-190°C, and control the pressure below 0.3MPa. After the addition reaction is completed, Lower the temperature to 65°C-75°C, add 0.33g of acetic acid to neutralize until the pH value reaches 5.0-8.0, and obtain cardanol polyoxyethylene ether. A certain amount of pentadecyl (en) base metaphenol (cardanol) polyoxyethylene ether, glucose 180g, solid acid TiO2 / SO2-4 and TiO2-ZrO2 / SO2-4 mixed catalyst 3.88g is dropped into the reactor, Stir evenly, depressurize to 4kPa, rapidly heat up to 90-120°C, keep warm for 2.5-4.0 hours, continuously pump out the generated water until the mixture in the reactor changes ...

Embodiment 3

[0036] Take 300g of refined cardanol and put it into a high-pressure reactor, add 0.6g of 50% potassium hydroxide solution, and carry out nitrogen replacement. ℃~130℃ for dehydration. After the dehydration is completed, raise the temperature to 135°C-160°C, add 132g of ethylene oxide to carry out the epoxidation reaction, control the temperature of the addition reaction at 130°C-190°C, and control the pressure below 0.3MPa. After the addition reaction is completed, Lower the temperature to 65°C-75°C, add 0.33g of acetic acid to neutralize until the pH value reaches 5.0-8.0, and obtain cardanol polyoxyethylene ether. A certain amount of pentadecyl (en) base metaphenol (cardanol) polyoxyethylene ether, glucose 180g, solid acid TiO2 / SO2-4 and TiO2-ZrO2 / SO2-4 mixed catalyst 4.3g is dropped into the reactor, Stir evenly, depressurize to 4kPa, rapidly heat up to 90-120°C, keep warm for 2.5-4.0 hours, continuously pump out the generated water until the mixture in the reactor changes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com