Co-polyester melt and method for preparing same

A technology of copolyester and melt, which is applied in the field of chemical fiber, can solve the problems of poor dyeing rate, poor moisture absorption, breathability and moisture retention, and lack of rheological properties of polyester fiber fabrics, so as to achieve good moisture absorption and moisture conduction, good product quality, The effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] This embodiment provides a five-component monomer copolyester melt and a preparation method thereof. The production process and conditions are as follows:

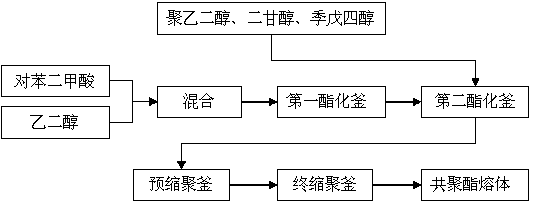

[0016] See attached figure 1 , which is a process flow chart for preparing a copolyester melt in a four-pot polymerization system with five-component monomers provided in this example. Put the mass fraction of 70% terephthalic acid (PTA) and mass fraction of 30% ethylene glycol (EG) as the first and second components, and inject the mixed ingredients into the slurry tank to use terephthalic acid and ethylene glycol The total amount is 100%, add catalyst ethylene glycol antimony 0.04% and additives trimethyl phosphate 0.01%, cobalt acetate 0.011%, sodium acetate 0.005%, mix and stir, and pump into the first esterification kettle through the slurry crank pump The esterification reaction then automatically flows into the second esterification tank through the liquid level difference, while adding the third component p...

Embodiment 2

[0022] According to the technical process of Example 1, after the esterification reaction in the first esterification tank is completed, in the second esterification tank, the total amount of terephthalic acid and ethylene glycol is 100%, and the mass fraction of 1.0% is added in the second esterification tank. The three-component polyethylene glycol, the fourth component diethylene glycol with a mass fraction of 0.007%, and the ethylene glycol (EG) solution of the fifth component pentaerythritol with a mass fraction of 0.01%, and a mass fraction of 0.3% titanium dioxide ( TiO 2 ), carry out esterification reaction, and see Table 3 for the process parameters of the five-component monomer copolymerization to prepare the copolyester melt, and see Table 4 for related performance indicators.

[0023] Table 3 Synthesis process of five-component copolyester melt

[0024] Process parameters Esterification Ⅰ Esterification II Precondensation final polycondensation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com