Outer casing material for electricity storage devices

A technology for electrical storage equipment and components, which is applied in the field of exterior components for electrical storage equipment, can solve problems such as cost reduction and thinning restrictions, stretched polyamide film dissolution, and insufficient scratch resistance, and achieves easy identification and realization of thin film Excellent effect of chemicalization and insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

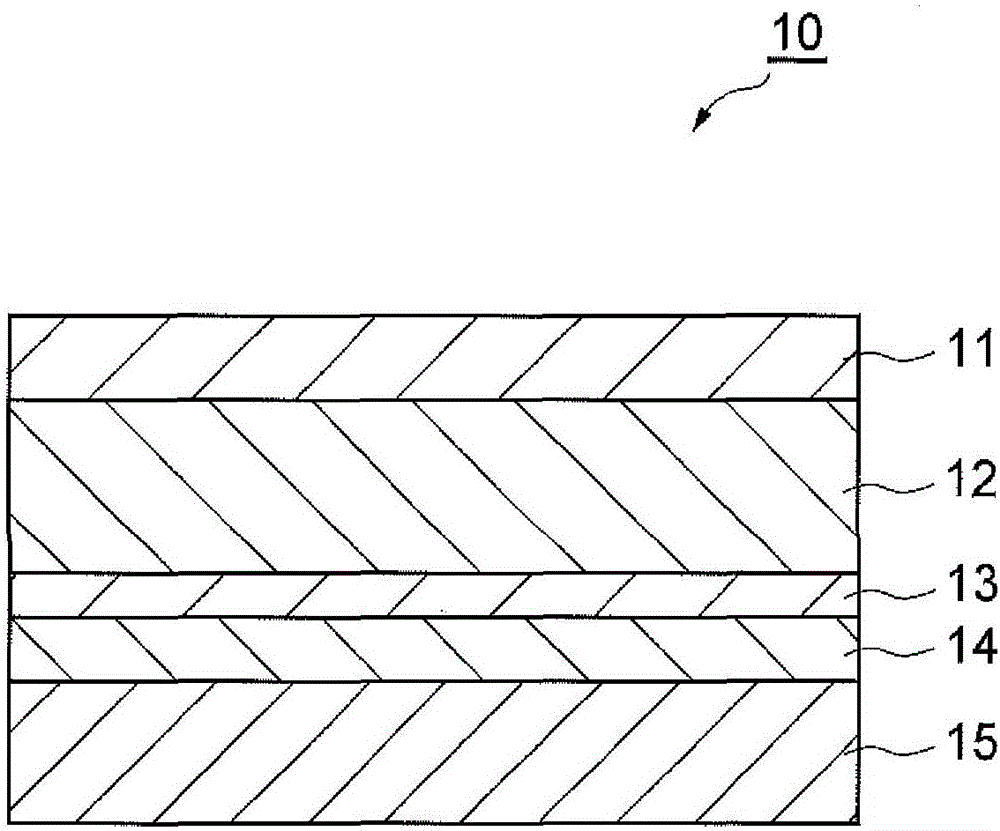

[0095] Toluene diisocyanate was added to a tetrafluoroethylene-vinyl copolymer resin, and titanium black with an average particle diameter of 2 μm was added so that the content thereof would be 5% by mass in the total solid content to prepare a coating liquid. On one side of the metal foil layer formed with 50 nm thick anti-corrosion treatment layers on both sides by cerium oxide sol treatment, the above-mentioned coating solution was applied so as to have a dry film thickness of 5 μm, and dried in an oven. An aging treatment was then carried out at 60°C for 7 days to promote curing. In addition, a polypropylene cast film was bonded to the surface of the metal foil layer opposite to the surface on which the coating film was formed using a polyurethane adhesive to produce an exterior member.

Embodiment 2

[0097] An exterior member was produced in the same manner as in Example 1 except that the addition amount of titanium black was 10% by mass.

Embodiment 3

[0099] An exterior member was produced in the same manner as in Example 1 except that the addition amount of titanium black was 20% by mass.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com