Flexible shape-stabilized phase-change thermal insulation material and preparation method thereof

A thermal insulation material and shape-setting phase change technology, which is applied in heat exchange materials, chemical instruments and methods, etc., can solve the problems of low latent heat of phase transition, low thermal conductivity, and complex structure of the thermal insulation part of the aircraft, so as to reduce the thermal conductivity. rate, improve thermal insulation effect, improve the effect of flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] A method for preparing a flexible shape-setting phase-change thermal insulation material, comprising the steps of:

[0038] 1) Batching: weigh the phase change medium, porous lightweight material, auxiliary agent and coating material respectively by the mass percentage of claim 1 for subsequent use;

[0039] 2) Adsorption of porous light materials: heat and melt the phase change medium, add porous light fillers, mix evenly, and pulverize after cooling;

[0040] 3) Composite coating material: use a mixer to knead the phase change material pulverized in step 2) and the coating material to a certain fineness, add additives and knead until uniform;

[0041] 4) Molding and curing: forming and curing by means of molding, extrusion and injection molding.

[0042] Said step 2) after pulverization, the particle size should be between 0.2-2mm.

[0043] The fineness in step 3) should be <50 μm.

[0044] The molding method in step 4) is any one of extrusion molding, compression ...

Embodiment 1

[0048] (1) 107 silicone rubber: docosane: aerogel: KH550: dibutyltin dilaurate: gasoline is weighed according to the mass ratio of 80:180:10:3:1:4 for standby;

[0049] (2) Heat docosane in an oven at 60°C, add airgel and mix evenly after it is completely melted, and pulverize it to a particle size of 1 mm after cooling to obtain phase change material A;

[0050] (3) Use a mixer to mix the phase change material A pulverized in step 2) with 107 silicone rubber until the fineness is less than 50 μm, add KH550, dibutyltin dilaurate, and gasoline and mix until uniform to obtain phase change material B ;

[0051] (4) Weigh 200g and put the mixed phase change material B evenly into a mold with a size of 200mm×200mm×3mm, use a molding machine to pressurize the mold at room temperature (1-5MPa) for 1-2 hours, after curing is complete The demoulding is a kind of flexible shape-setting phase change thermal insulation material.

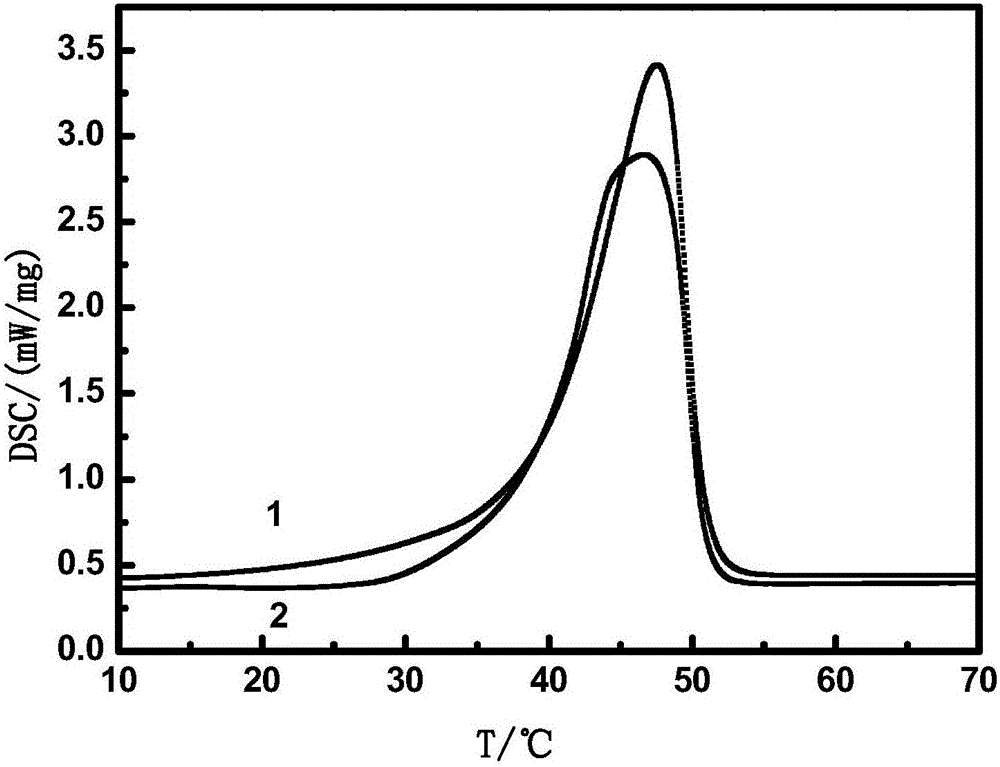

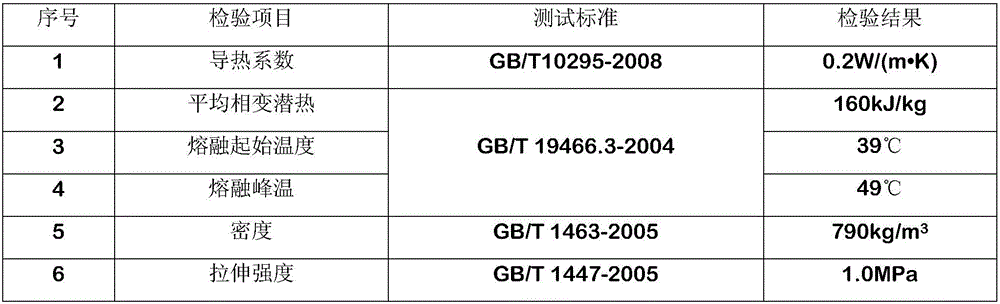

[0052] The enthalpy change of the prepared flexible shap...

Embodiment 2

[0056] (1) 108 silicone rubber: butylene glycol: aerogel: tetraethyl orthosilicate: dibutyltin dilaurate: gasoline is weighed according to the mass ratio of 100:300:8:3:1:4 for standby;

[0057] (2) Heat butaline in an oven at 130°C, add airgel and mix evenly after it is completely melted, and crush it to a particle size of about 1mm after cooling;

[0058] (3) Use a mixer to mix the phase change material pulverized in step 2) with 108 silicone rubber until the fineness is less than 50 μm, add ethyl orthosilicate, dibutyltin dilaurate, and gasoline and mix until uniform;

[0059] (4) Weigh 300g and put the mixed phase change material evenly into a mold with a size of 200×200×3mm, use a molding machine to pressurize the mold at room temperature (1-5MPa) for 1-2 hours, and remove it after curing is complete. The mold is a kind of flexible shape-setting phase-change thermal insulation material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com