High-acid-dissolution composite plugging solution capable of improving formation pressure bearing capability

A technology of pressure-bearing capacity and leak-stopping fluid, applied in the directions of drilling compositions, chemical instruments and methods, etc., can solve the problems of low leak-stopping pressure-bearing capacity, low leak-stopping aging effect, and poor plugging capacity, etc. Good leakage effect, improve plugging capacity and pressure bearing capacity, and reduce dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

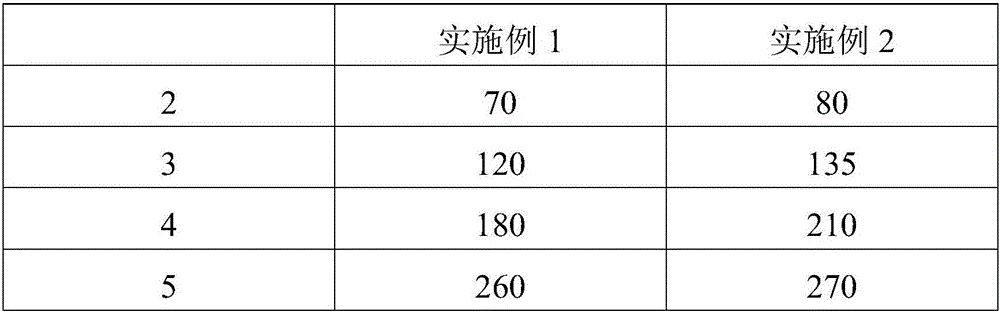

Embodiment 1

[0069] Preparation of highly acid-soluble composite plugging fluid for improving formation pressure bearing capacity

[0070] (1) Raw material preparation

[0071] Degradable fiber FCL 1g; high-strength ductile plugging agent GYD 15g; acid-soluble gel plugging agent SHD 8g; drilling mud 76g.

[0072] Among them, the degradable fiber FCL and the acid-soluble gel plugging agent SHD were purchased from Beijing Kemax Oilfield Chemical Technology Co., Ltd.

[0073] High-strength ductile plugging agent GYD is prepared by the following method:

[0074] (a) Prepare raw materials:

[0075] Aluminum powder 55g; expandable graphite 12g; silicon carbide 3g; calcium oxide 10g; floating beads 10g; barium carbonate 3g; and manganese dioxide 0.5g;

[0076] Wherein, the particle size of the aluminum powder is 200-400 μm.

[0077] (b) Add aluminum powder into the crucible and heat to 720°C to completely melt the raw material.

[0078] (c) pulverizing expandable graphite and silicon carbide...

Embodiment 2

[0087] Preparation of highly acid-soluble composite plugging fluid for improving formation pressure bearing capacity

[0088] (1) Raw material preparation

[0089] Degradable fiber FCL 0.8g; high-strength ductile plugging agent GYD 10g; acid-soluble gel plugging agent SHD 6g; drilling mud 83.2g.

[0090] Among them, the degradable fiber FCL and the acid-soluble gel plugging agent SHD were purchased from Beijing Kemax Oilfield Chemical Technology Co., Ltd.

[0091] High-strength ductile plugging agent GYD is prepared by the following method:

[0092] (a) Prepare raw materials:

[0093] 45g of aluminum-magnesium alloy powder; 10g of expandable graphite; 2g of silicon carbide; 8g of calcium oxide; 8g of floating beads; 3g of barium carbonate; and 0.5g of manganese dioxide;

[0094] Wherein, the particle size of the aluminum-magnesium alloy powder is 200-400 μm.

[0095] (b) Add aluminum powder into the crucible and heat to 710°C to completely melt the raw material.

[0096] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com