Supported phosphorus-doping rhodium-nickel catalyst as well as preparation method and application thereof

A nickel catalyst and phosphorus doping technology, applied in the field of nanomaterials, can solve the problems of limiting the application of metal nanoparticle catalysts, cumbersome process, and particle aggregation, and achieve good catalytic dehydrogenation effect, simple process, and small particle size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

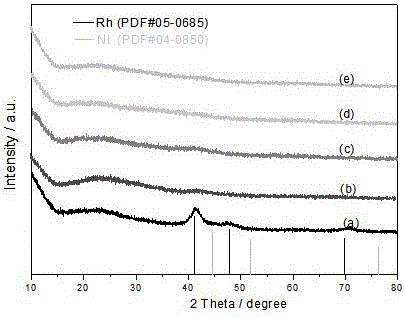

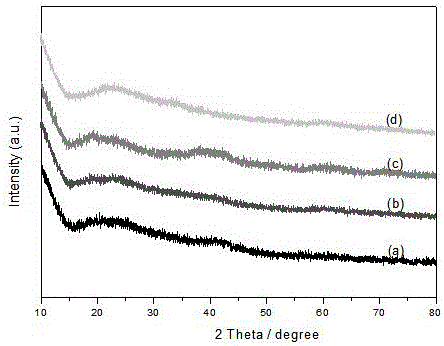

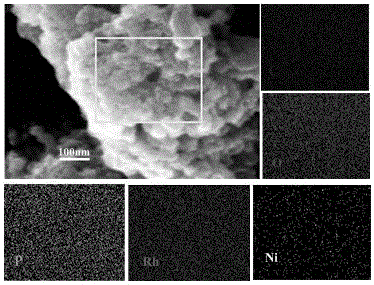

[0026] 1) For the preparation of supported phosphorous-doped rhodium-nickel nanoparticles, at room temperature, 10 mg of graphene oxide and 8.8 mg of sodium hypophosphite were sequentially added to an ultrapure aqueous solution, and then ultrasonicated for 10 minutes to dissolve and disperse them. Stir at room temperature.

[0027] 2) Take 0.8 mL of 0.1 mol / L rhodium salt solution and 0.2 mL of 0.1 mol / L nickel salt solution, and add them in sequence to the above aqueous solution and stir.

[0028] 3) Then take 400mg of sodium hydroxide, make it into a 2mol / L aqueous solution, add it into the above solution and stir. Then take 37.8 mg of sodium borohydride, make it into 1 mol / L aqueous solution, slowly add it dropwise to the above solution, and stir continuously at room temperature for 2 hours, it can be observed that the solution slowly turns from orange yellow to black.

[0029] 4) After the reduction reaction is completed, put the aqueous solution containing the metal cata...

Embodiment 2

[0032] 1) For the preparation of supported phosphorous-doped rhodium-nickel nanoparticles, 10 mg graphene oxide and 17.6 mg sodium phosphate were sequentially added to an ultrapure aqueous solution, and then the solution was ultrasonicated for 10 minutes to dissolve and disperse it, and then Stir at room temperature.

[0033] 2) Take 0.8 mL of 0.1 mol / L rhodium salt solution and 0.2 mL of 0.1 mol / L nickel salt solution, and add them in sequence to the above aqueous solution and stir. In order to prepare metal nanoparticles with different rhodium-nickel ratios, the feeding ratios of rhodium salt and nickel salt can be adjusted to 0.6mL / 0.4mL, 0.4mL / 0.6mL and 0.2mL / 0.8mL, respectively.

[0034] 3) Then take 400mg of sodium hydroxide, make it into a 2mol / L aqueous solution, add it into the above solution and stir. Take 37.8 mg of sodium borohydride, make it into 1mol / L aqueous solution, slowly add it dropwise to the above solution, and continue stirring at room temperature for 2...

Embodiment 3

[0038] 1) For the preparation of supported phosphorous-doped rhodium-nickel nanoparticles, 10mg graphene oxide is used as a carrier, then 26.4mg sodium hypophosphite is added to the ultrapure aqueous solution, and the solution is ultrasonicated for 10 minutes to dissolve and disperse , stirred at room temperature. In order to prepare metal nanocatalysts with different phosphorus doping content, the dosage of sodium hypophosphite can be adjusted to 35.2 mg.

[0039]2) Take 0.8 mL of 0.1 mol / L rhodium salt solution and 0.2 mL of 0.1 mol / L nickel salt solution, and add them in sequence to the above aqueous solution and stir.

[0040] 3) Then take 400mg of sodium hydroxide, make it into a 2mol / L aqueous solution, add it into the above solution and stir. Then take 37.8 mg of sodium borohydride, make it into 1 mol / L aqueous solution, slowly add it dropwise to the above solution, and stir continuously at room temperature for 2 hours, it can be observed that the solution slowly turns...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com