Activated sludge deep dewatering method

A deep dehydration and activated sludge technology, which is applied in water/sludge/sewage treatment, sludge treatment, chemical instruments and methods, etc., can solve the problems of mud cake expansion, refractory biodegradation, and impact on treatment and disposal. Achieve the effect of reducing the need for odor treatment, simplifying the conditioning process, and reducing equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

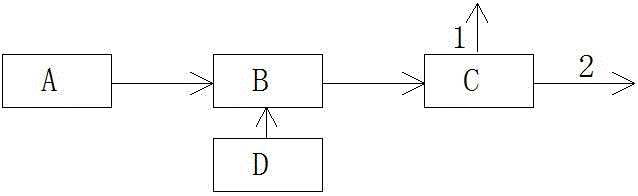

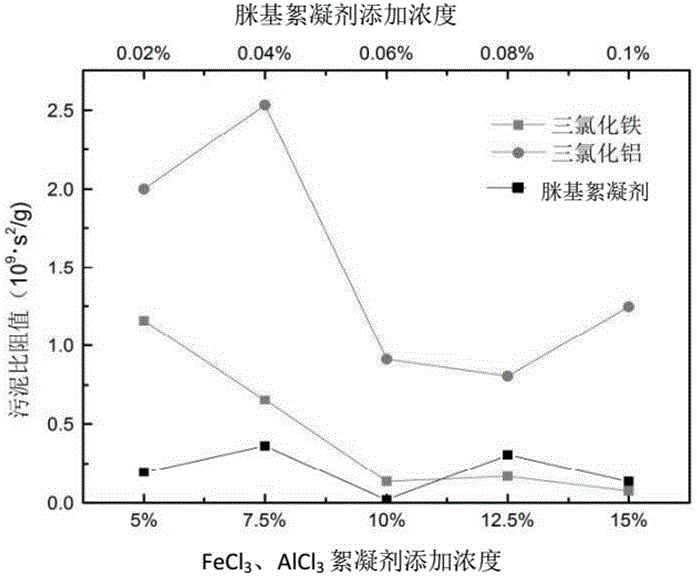

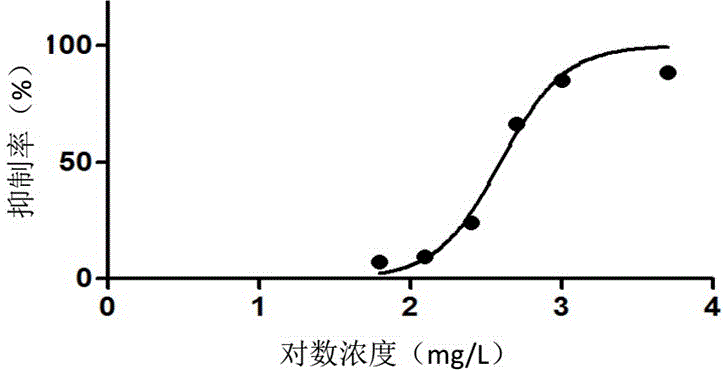

Method used

Image

Examples

Embodiment 1

[0039] Take the sludge from the thickening tank of a sewage treatment plant in Zhejiang, the water content is about 96%, add polyethylene amidine solution with a concentration of 0.1% to the sludge, and the added amount is 0.8% of the dry basis of the sludge, and stir in the mixing tank After 10 minutes, the sludge forms flocs. The flocculated sludge is discharged into the plate-and-frame filter press. After pressing for a certain period of time, the plate is opened, and the sludge cake from the filter press falls automatically. The sludge in different mud cake positions is taken to measure the moisture content, and the moisture content is measured. was 58.5%.

Embodiment 2

[0041] Take the sludge from the thickening tank of a sewage treatment plant in Shanghai, the water content is about 95.5%, add 0.1% polyvinyl amidine solution to the sludge, the amount added is 1.0% of the dry basis of the sludge, and stir in the mixing tank for 10 minutes Sludge forms flocs. The flocculated sludge is discharged into the plate-and-frame filter press. After pressing for a certain period of time, the plate is opened, and the sludge cake from the filter press falls automatically. The sludge in different mud cake positions is taken to measure the moisture content, and the moisture content is measured. was 56.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com