High-density polyethylene resin-based nanocomposite material and preparation method thereof

A technology of high-density polyethylene and nano-composite materials, which is applied in the field of composite materials of high-density polyethylene materials, can solve the problems of not being able to give full play to the excellent performance of graphene, easy agglomeration, and reducing the performance of matrix resins, and achieve excellent mechanical properties and Effects of thermal properties, promotion of dispersion, and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Preparation of graphite oxide: Add 115mL of 98% concentrated sulfuric acid into a dry beaker, cool it to below 4°C with an ice-water bath, add 5gNGP and 2.5gNaNO under vigorous stirring 3 mixture, and then slowly add 15g of KMnO 4 , and control the temperature of the reaction system below 20°C, continue to stir the reaction for 5 minutes, then raise the temperature of the system to 35±3°C, stir at constant temperature for 30 minutes, then add 230mL of deionized water under vigorous stirring. Transfer the above system into a heated oil bath, keep the system reaction temperature at 98°C for 15 minutes, then add 355mL of hot deionized water for high-temperature hydrolysis, add 30mL of H 2 o 2 Neutralize the unreacted strong oxidant, suction filter while it is hot, wash thoroughly with 5% hydrochloric acid and deionized water, and dry in a vacuum oven at 90°C for 24 hours to obtain graphite oxide. Graphene oxide is obtained by ultrasonically dispersing graphite oxide.

...

Embodiment 2

[0057] The preparations of ethylenediamine-grafted graphene oxide and acidified carbon nanotubes were the same as in Example 1. In the preparation process of high-density polyethylene resin-based nanocomposites, the mixture of 0.075g of ethylenediamine grafted graphene oxide and acidified carbon nanotubes and 14.925g of HDPE-g-MAH were subjected to the same process as in Example 1 After melt blending, a high-density polyethylene resin-based nanocomposite material with a filler mass content of 0.5% was obtained.

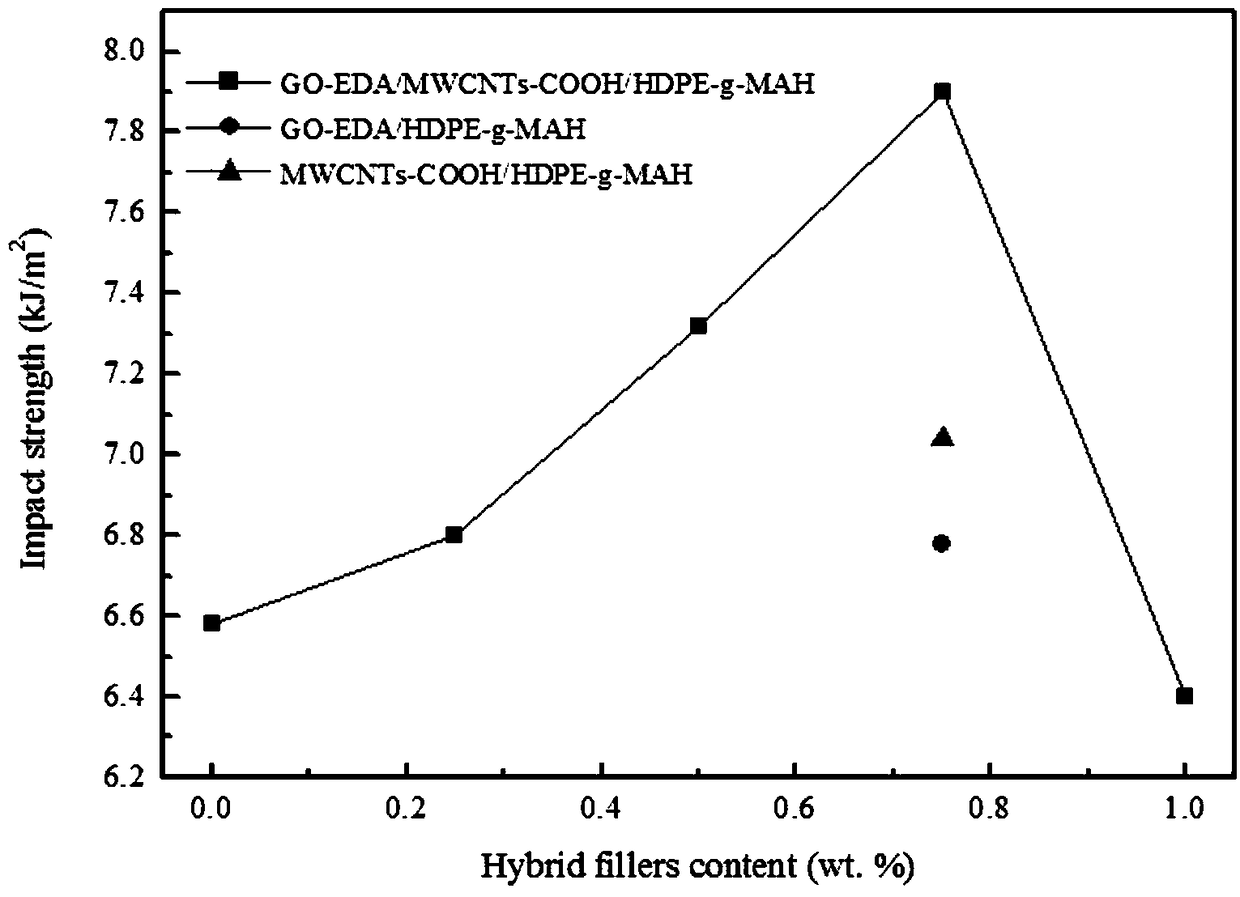

[0058] The test sample preparation and test conditions of the high-density polyethylene resin-based nanocomposite are the same as in Example 1, and the tensile and impact test results are shown in Table 1. It can be seen that compared with pure HDPE-g-MAH, the tensile strength and impact strength of the HDPE resin-based nanocomposites using ethylenediamine-grafted graphene oxide and acidified carbon nanotube mixtures as fillers are improved, respectively up 16.1% and...

Embodiment 3

[0064] The preparations of ethylenediamine-grafted graphene oxide and acidified carbon nanotubes were the same as in Example 1. In the preparation process of high-density polyethylene resin-based nanocomposites, the mixture of 0.1125g of ethylenediamine grafted graphene oxide and acidified carbon nanotubes and 14.8875g of HDPE-g-MAH were subjected to the same process as in Example 1 After melt-blending, a high-density polyethylene resin-based nanocomposite material with a filler mass content of 0.75% was obtained.

[0065] The test sample preparation and test conditions of the high-density polyethylene resin-based nanocomposite are the same as in Example 1, and the tensile and impact test results are shown in Table 1. It can be seen that the tensile strength and impact strength of the HDPE resin-based nanocomposites using a mixture of ethylenediamine-grafted graphene oxide and acidified carbon nanotubes are improved, respectively, compared with pure HDPE-g-MAH 11.9% and 20%. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com