Non-solvent type epoxy floor paint and preparation method thereof

An epoxy floor and solvent-free technology, applied in the field of coatings, can solve the problems of low comprehensive performance, non-environmental protection, and better performance of solvent-based floor coatings, so as to improve antifouling, compactness, and comprehensive corrosion resistance and anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A solvent-free epoxy floor coating is prepared from the following raw materials by the following preparation method, and the amounts of the following raw materials are in parts by weight:

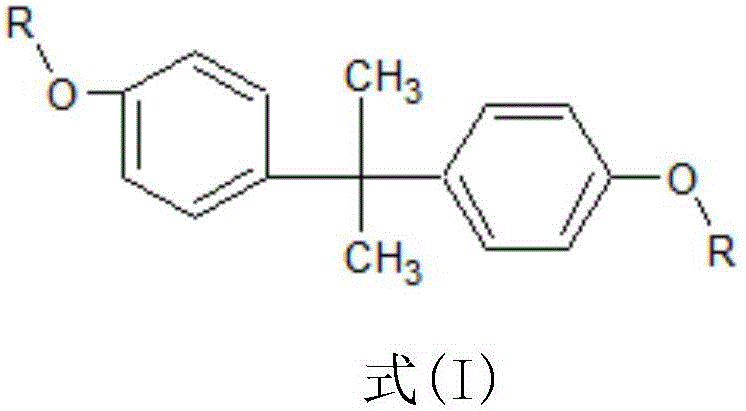

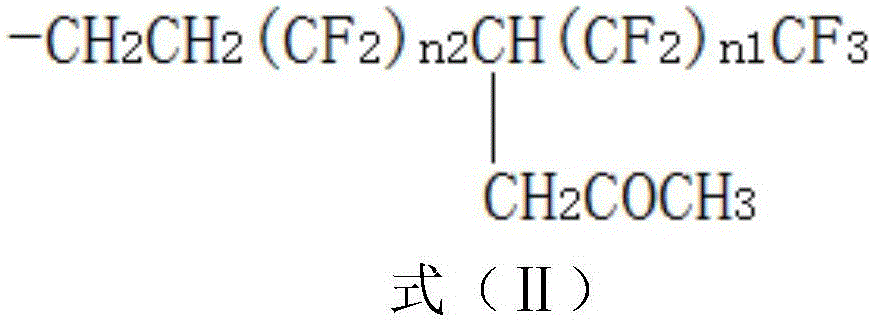

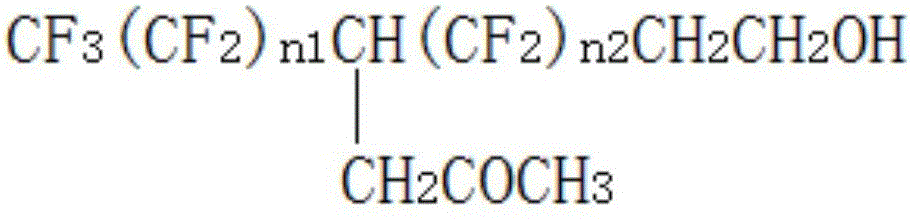

[0049] (1) Preparation of organic fluorine epoxy compound: 4 parts of perfluoroalkyl ethyl acrylate, 3 parts of catalyst, 65 parts of bisphenol A epoxy resin, 28 parts of butyl acetate are added to the reaction kettle successively, at 70- Stirring at a temperature of 80° C. for 2-3 hours to obtain a modified organic fluorine epoxy compound;

[0050] (2) Add 45 parts of liquid epoxy resin and 1 part of organic fluorine epoxy compound into the dispersion mixer, start stirring, and at a speed of 400-600r / min, add 6 parts of epoxy reactive diluent, 0.3 parts of moistening Wetting agent, 0.3 part of dispersant, 0.8 part of nano silicon dioxide, 0.3 part of defoamer and 10 parts of pigment, stir evenly;

[0051] (3) At a speed of 400-600r / min, add 3 parts of graphite powder, 12 parts of b...

Embodiment 2

[0056] A solvent-free epoxy floor coating is prepared from the following raw materials by the following preparation method, and the amounts of the following raw materials are in parts by weight:

[0057] (1) Preparation of organic fluorine epoxy compound: 4.5 parts of perfluoroalkyl ethyl acrylate, 5 parts of catalyst, 75 parts of bisphenol A epoxy resin, 15.5 parts of butyl acetate are added to the reaction kettle successively, at 70- Stirring at a temperature of 80° C. for 2-3 hours to obtain a modified organic fluorine epoxy compound;

[0058] (2) Add 40 parts of liquid epoxy resin and 5 parts of organic fluorine epoxy compound into the dispersion mixer, start stirring, and at a speed of 400-600r / min, add 8 parts of epoxy reactive diluent, 0.4 parts of moistening Wet agent, 0.3 part of dispersant, 1 part of nano silicon dioxide, 0.4 part of defoamer and 10 parts of pigment, stir evenly;

[0059] (3) At a rotating speed of 400-600r / min, add 5 parts of graphite powder, 11 pa...

Embodiment 3

[0064] A solvent-free epoxy floor coating is prepared from the following raw materials by the following preparation method, and the amounts of the following raw materials are in parts by weight:

[0065] (1) Preparation of organic fluorine epoxy compound: 6 parts of perfluoroalkyl ethyl acrylate, 3 parts of catalyst, 70 parts of bisphenol A epoxy resin, 21 parts of butyl acetate are added to the reaction kettle successively, at 70-80 Stirring at a temperature of °C for 2-3 hours to obtain a modified organic fluorine epoxy compound;

[0066] (2) Add 42 parts of liquid epoxy resin and 3 parts of organic fluorine epoxy compound into the dispersion mixer, start stirring, and at a speed of 400-600r / min, add 7 parts of epoxy reactive diluent, 0.5 parts of moistening Wet agent, 0.3 part of dispersant, 0.7 part of nano silicon dioxide, 0.5 part of defoamer and 8 parts of pigment, stir evenly;

[0067] (3) At a speed of 400-600r / min, add 4 parts of graphite powder, 13 parts of barium ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com