Aluminum silicate red phosphor and preparation method thereof

A red phosphor, aluminosilicate technology, applied in chemical instruments and methods, luminescent materials, electrical components, etc., can solve the problems of weak absorption, limited application range, poor stability of fluoride, etc., and achieve strong absorption and high luminescence efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

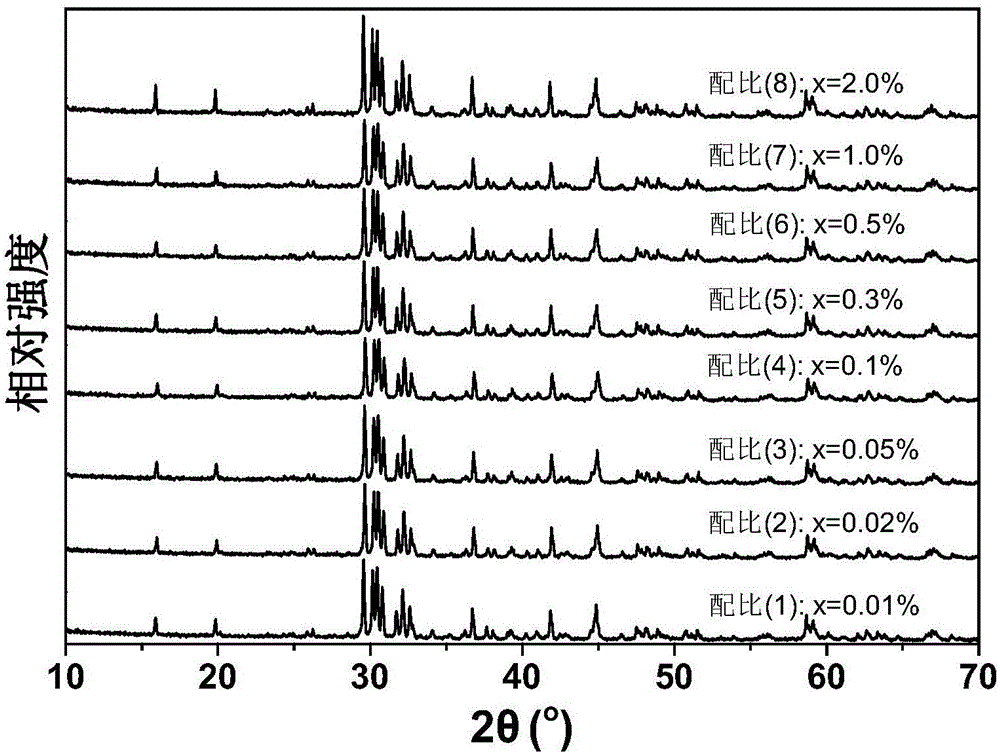

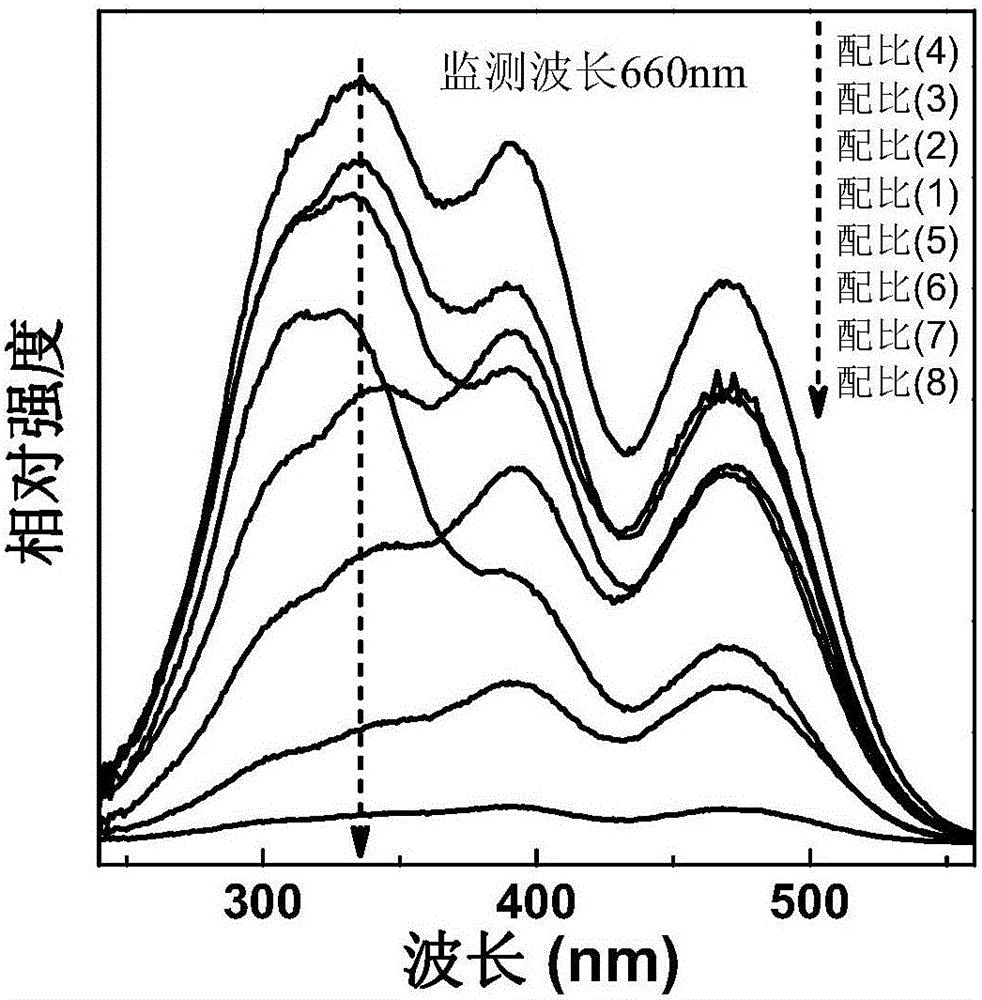

[0038] Select strontium carbonate, aluminum hydroxide, silicon dioxide, manganese carbonate and boric acid as the starting compound raw materials, and weigh five kinds of compound raw materials respectively according to the molar ratio of each element, totally 8 groups, and the proportions are as follows:

[0039] (1) Sr:Al:Si:Mn:B=3:9.999:1:0.001:0.5, corresponding to x=0.01%, y=5%;

[0040] (2) Sr:Al:Si:Mn:B=3:9.998:1:0.002:0.5, corresponding to x=0.02%, y=5%;

[0041] (3) Sr:Al:Si:Mn:B=3:9.995:1:0.005:0.5, corresponding to x=0.05%, y=5%;

[0042] (4) Sr:Al:Si:Mn:B=3:9.990:1:0.010:0.5, corresponding to x=0.1%, y=5%;

[0043] (5) Sr:Al:Si:Mn:B=3:9.970:1:0.030:0.5, corresponding to x=0.3%, y=5%;

[0044] (6) Sr:Al:Si:Mn:B=3:9.950:1:0.050:0.5, corresponding to x=0.5%, y=5%;

[0045] (7) Sr:Al:Si:Mn:B=3:9.900:1:0.100:0.5, corresponding to x=1.0%, y=5%;

[0046] (8) Sr:Al:Si:Mn:B=3:9.800:1:0.200:0.5, corresponding to x=2.0%, y=5%;

[0047] The total weight of the control mixtu...

Embodiment 2

[0054] Select strontium carbonate, aluminum hydroxide, silicon dioxide, manganese carbonate and boric acid as starting compound raw materials, according to the molar ratio of each element Sr:Al:Si:Mn:B=3:9.990:1:0.010:0.5, corresponding to x =0.1%, y=5%; five kinds of compound raw materials were weighed respectively, and the total weight of the control mixture was 15 grams. After grinding and mixing 15 grams of the mixture, put it into a corundum crucible, and then put the crucible into a high-temperature electric furnace. The heating rate is precisely controlled, and the sample is pre-fired at 800°C for 5 hours. Take out the pre-fired sample, grind it again and divide it into several parts, burn it under the air at temperature T (T=1200, 1250, 1300, 1350, 1450, 1500, 1550°C) for 5 hours, take it out and grind it again Afterwards, burn again at temperature T (T=1200, 1250, 1300, 1350, 1450, 1500, 1550°C) for 5 hours in the air, and cool naturally with the furnace to obtain te...

Embodiment 3

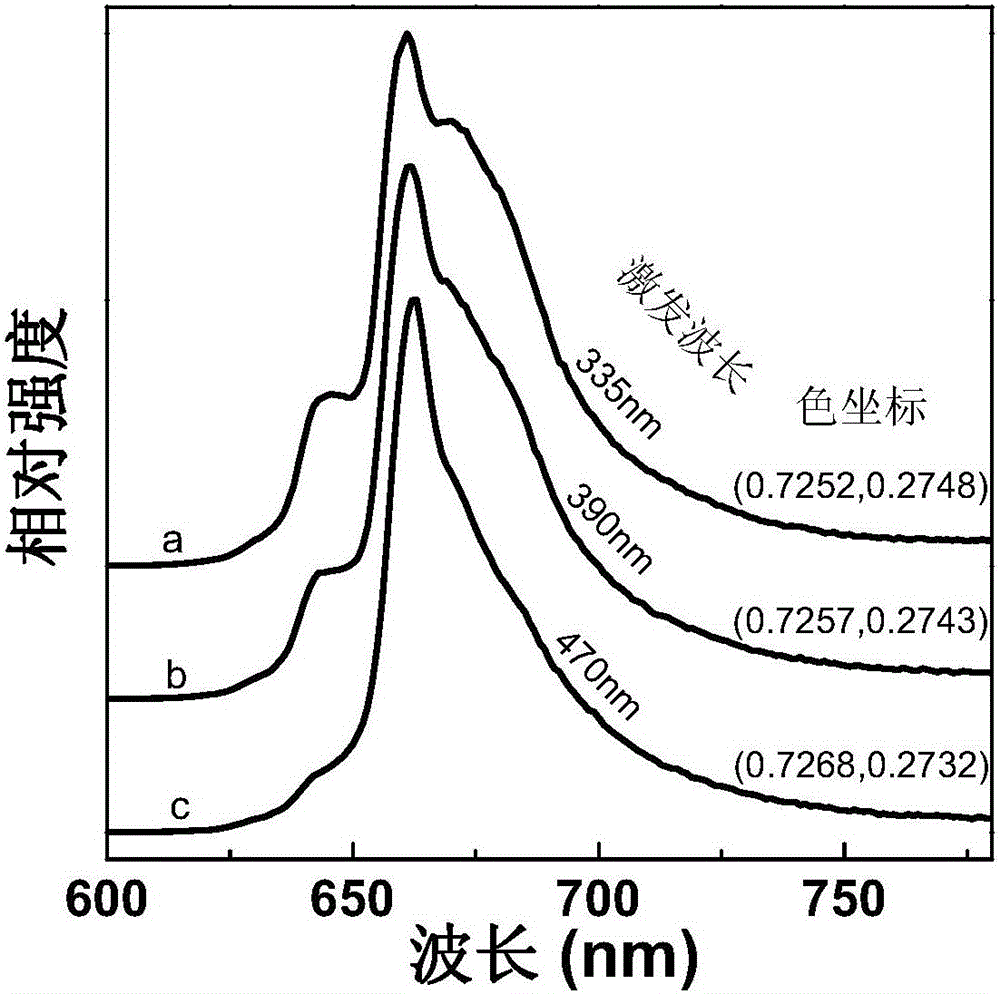

[0056] Select strontium oxide, aluminum hydroxide, silicon dioxide, manganese oxide and boric acid as starting materials, according to the molar ratio of each element Sr:Al:Si:Mn:B=3:9.999:1:0.001:0.2, corresponding to x= 0.01%, y=2%; five kinds of raw materials were weighed respectively, and the total weight of the control mixture was 5 grams. After grinding and mixing 5 grams of the mixture, put it into a corundum crucible, and then put the crucible into a high-temperature electric furnace. The heating rate is precisely controlled, and the sample is pre-fired at 500°C for 10 hours. Take out the pre-fired sample, grind and mix it again, burn it at 1550°C for 2 hours in an oxygen atmosphere, take it out and grind it again, burn it at 1550°C for 2 hours in an oxygen atmosphere, and cool it naturally with the furnace Tetravalent manganese ion doped strontium aluminosilicate red luminescent material. X-ray diffraction analysis showed that it was Sr 3 al 10 SiO 20 crystal pha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fluorescence lifetime | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com