A joint determination method of chromium molybdenum aluminum titanium content in low alloy steel

A low-alloy steel and determination method technology, applied in the field of detection and analysis, can solve the problems of poor color stability, difficulty in joint detection of chromium elements, poor operability, etc., to promote application development and simple determination method , the effect of increased safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

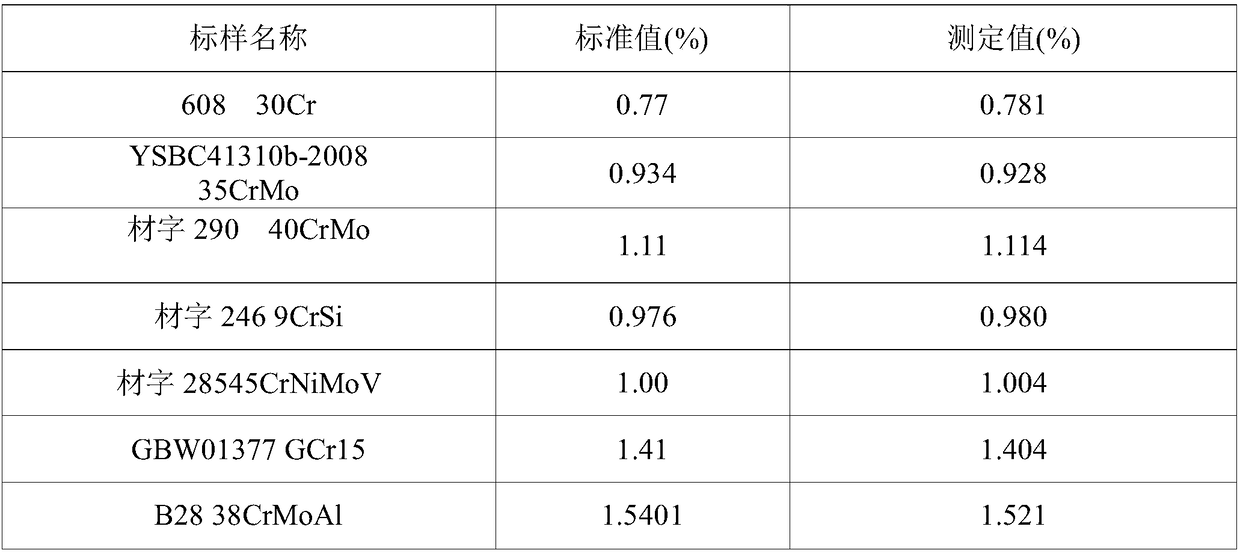

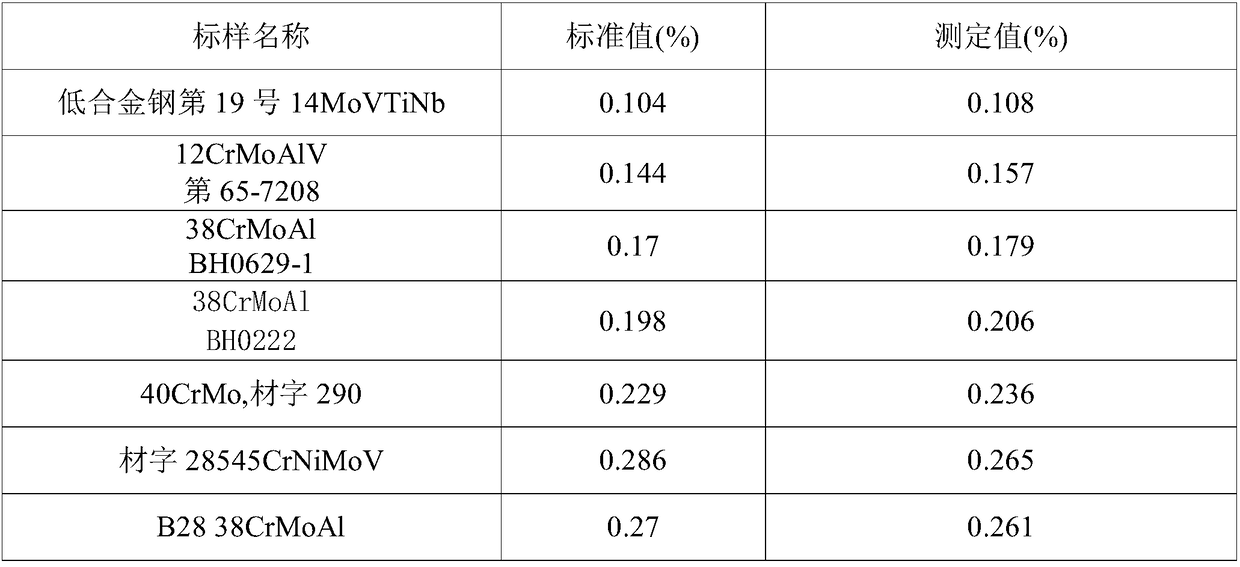

Examples

Embodiment 1

[0032] A joint determination method of chromium molybdenum aluminum titanium content in low alloy steel:

[0033] (1) Preparation of test solution: Weigh 0.2 g of low alloy steel sample into a 50.00 ml steel measuring bottle, add 10.0 ml of dissolving solution, heat to dissolve at 60-80°C, heat to 140-200°C to fill the bottle with high Chloric acid white smoke, continue to heat at 210°C until perchloric acid smoke reaches the bottle mouth for 30 seconds, cool down, add water to make up to 50.00 ml, mix well, and get the test solution;

[0034] (2) Determination of chromium: the test solution is at a wavelength of 430 nanometers, with a cuvette of 1 cm, and water is used as a reference solution to measure the absorbance value of chromium;

[0035] (3) Determination of molybdenum: Take 5.00 ml of test solution and place it in a 50.00 ml volumetric flask, add 5.0 ml of sulfuric acid and 10.0 ml of ascorbic acid and mix well, then add 3.00 ml of ammonium thiocyanate, add water to ...

Embodiment 2

[0041] A joint determination method of chromium molybdenum aluminum titanium content in low alloy steel:

[0042] (1) Preparation of test solution: Weigh 0.2 g of low alloy steel sample into a 50.00 ml steel measuring bottle, add 10.0 ml of dissolving solution, heat to dissolve at 60-80°C, heat to 140-200°C to fill the bottle Perchloric acid white smoke, continue to heat at 210°C until the perchloric acid smoke reaches the bottle mouth for 30 seconds, cool down, add water to make up to 50.00 ml, mix well, and get the test solution;

[0043] (2) Determination of chromium: the test solution is at a wavelength of 430 nanometers, with a cuvette of 1 cm, and water is used as a reference solution to measure the absorbance value of chromium;

[0044] (3) Determination of molybdenum: put 5.00 ml of test solution in a 50.00 ml volumetric flask, add 5.0 ml of sulfuric acid and 10.0 ml of ascorbic acid and mix well, then add 3.00 ml of ammonium thiocyanate, add water to make up to 50.00 ...

Embodiment 3

[0050] A joint determination method of chromium molybdenum aluminum titanium content in low alloy steel:

[0051] (1) Preparation of test solution: Weigh 0.2 g of low alloy steel sample into a 50.00 ml steel measuring bottle, add 10.0 ml of dissolving solution, heat to dissolve at 60-80°C, heat to 140-200°C to fill the bottle Perchloric acid white smoke, continue to heat at 210°C until the perchloric acid smoke reaches the bottle mouth for 30 seconds, cool down, add water to make up to 50.00 ml, mix well, and get the test solution;

[0052] (2) Determination of chromium: the test solution is at a wavelength of 430 nanometers, with a cuvette of 1 cm, and water is used as a reference solution to measure the absorbance value of chromium;

[0053] (3) Determination of molybdenum: Take 5.00 ml of test solution and place it in a 50.00 ml volumetric flask, add 5.0 ml of sulfuric acid and 10.0 ml of ascorbic acid and mix well, then add 3.00 ml of ammonium thiocyanate, add water to mak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com