Method for improving crystallinity of perovskite

A perovskite and crystalline technology, applied in the field of solar cells, can solve the problems of unsatisfactory crystalline properties of perovskite thin films, and achieve the effects of broad industrial application prospects, low energy consumption, and low energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing and example.

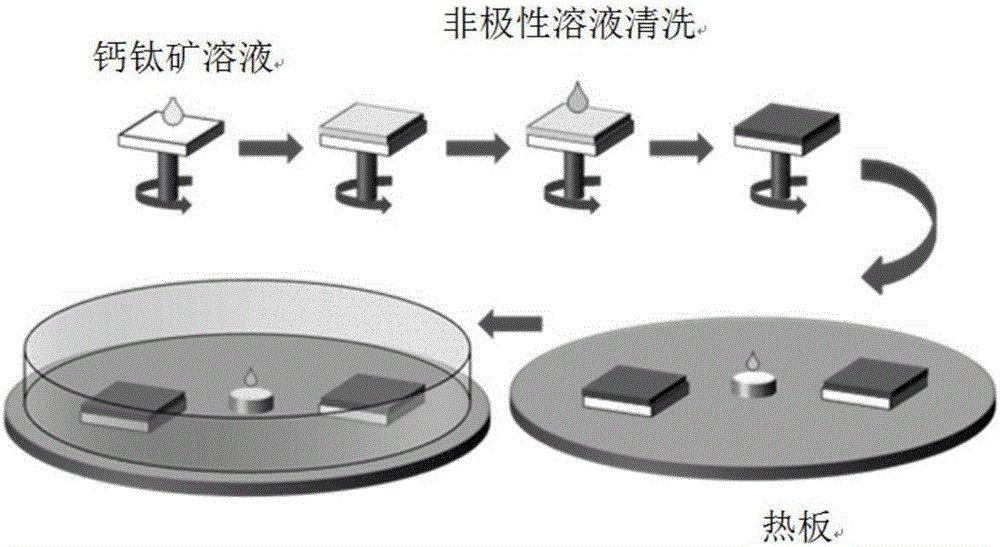

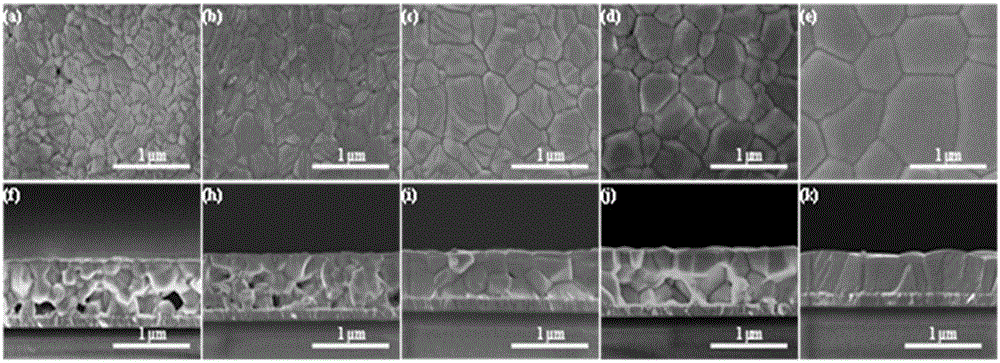

[0020] The glass substrate covered with ITO was ultrasonically washed with detergent, acetone, and ethanol for 30 minutes, and dried with a nitrogen gun. Preparation of CH3NH3PbI with a thickness of 300nm by spin coating 3-x Cl x Perovskite light absorbing layer. Heat at 100°C for 5 minutes. The pre-annealed samples were transferred to a heating stage at 100°C. Place a crucible with a diameter of 1 cm on the heating stage, use a pipette gun to draw 10 μl of dimethyl sulfoxide dropwise into the crucible, and then quickly cover the sample and the crucible with a glass cover. The crucible is heated, and the solvent inside turns into steam and evaporates, forming a dimethyl sulfoxide solvent atmosphere in the lid. The solvent annealing time was 30min. Such as figure 1 shown.

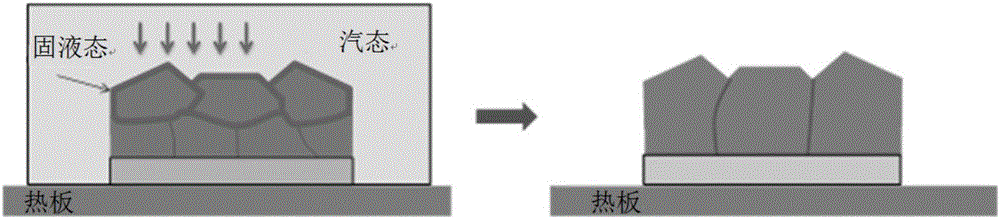

[0021] The principle of annealing under dimethyl sulfoxide solvent atmosphere is a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com