A perovskite nanostructured plasmonic laser

A plasma and perovskite technology, applied in the fields of micro-nano photonics and lasers, can solve the problems of lack of cavity feedback, high Auger loss, and low quantum efficiency of semiconducting gain media in lasers, and achieve low cavity feedback and Auger loss. The effect of high, high fluorescence yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

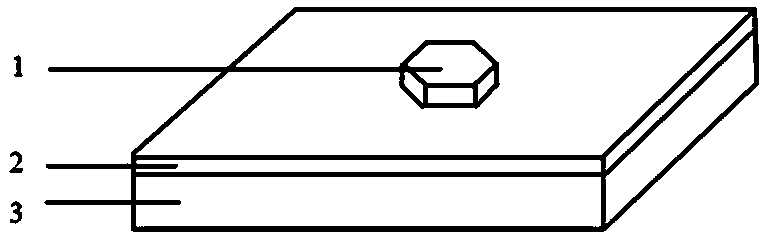

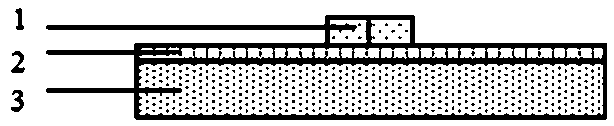

[0015] Evaporate silver with a thickness of 100 nanometers on a flat silicon substrate, and then vapor-deposit silicon dioxide with a thickness of 5 nanometers on the silver surface to form a silver / silicon dioxide composite film; make lead iodide perovskite nanosheets CH 3 NH 3 PB 3 , wherein the lead iodide perovskite nanosheet thickness is 150 nanometers, the cross-sectional shape is a regular hexagon, and the side length of the regular hexagon is 32 microns, and then the lead iodide perovskite nanosheet is moved to the silver / silicon dioxide On the composite film, a silver / silicon dioxide / lead iodide perovskite nanosheet structure is formed. In this structure, the refractive index of silver is 0.14+5.14i, the thickness of silver is 100 nanometers, and the refractive index of silicon dioxide is 1.45 , the thickness is 5 nm, the refractive index of the lead iodide perovskite nanosheet is 2.54+0.03i, the thickness is 150 nm, the cross-sectional shape is a regular hexagon, a...

Embodiment 2

[0017] Evaporate silver with a thickness of 100 nanometers on a silicon substrate with a flat surface, and then vapor-deposit silicon dioxide with a thickness of 10 nanometers on the silver surface to form a silver / silicon dioxide composite film; make lead bromide perovskite nanosheets CH 3 NH 3 PbBr 3 , wherein the lead bromide perovskite nanosheet thickness is 50 nanometers, the cross-sectional shape is a regular hexagon, and the side length of the regular hexagon is 32 microns, and then the lead bromide perovskite nanosheet is moved to the silver / silicon dioxide On the composite film, a silver / silicon dioxide / lead bromide perovskite nanosheet structure is formed. In this structure, the refractive index of silver is 0.14+5.14i, the thickness of silver is 100 nanometers, and the refractive index of silicon dioxide is 1.45 , the thickness is 10 nanometers, the refractive index of the lead bromide perovskite nanosheet is 2.86+0.04i, the thickness is 50 nanometers, the cross-s...

Embodiment 3

[0019] Evaporate aluminum with a thickness of 100 nanometers on a flat sapphire surface, and then vapor-deposit magnesium fluoride with a thickness of 8 nanometers on the silver surface to form an aluminum / magnesium fluoride composite film; make lead chloride perovskite nanosheet CH 3 NH 3 PbCl 3 , wherein the lead chloride perovskite nanosheet thickness is 200 nanometers, the cross-sectional shape is a regular triangle, and the side length of the regular triangle is 48 microns, and then the lead bromide perovskite nanosheet is moved to the aluminum / magnesium fluoride On the composite film, an aluminum / magnesium fluoride / lead chloride perovskite nanosheet structure is formed. In this structure, the refractive index of aluminum is 1.48+3.14i, and the thickness is 100 nanometers. The refractive index of magnesium fluoride is 1.38, and the thickness The lead chloride perovskite nanosheet has a refractive index of 3.06+0.04i, a thickness of 200 nanometers, a regular triangle in c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com