Manufacturing method for chromium-molybdenum target

A manufacturing method and target material technology, which is applied in metal material coating process, ion implantation plating, coating, etc., can solve the problems that cannot meet the quality requirements of high-end manufacturing target materials, and meet the requirements of purity and density , Improve the density and strength, and the effect of uniform microstructure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] It can be seen from the background technology that there is a problem that it is difficult to manufacture high-quality chromium-molybdenum targets in the prior art. Now combine the production and use of chromium molybdenum target to analyze the cause of the problem:

[0038] The chromium-molybdenum target used in sputtering technology generally requires material purity greater than or equal to 99.9%, relatively high density (requires greater than or equal to 99%), and also requires uniform microstructure and no crack defects. However, the chromium-molybdenum target produced by the prior art has a low density and cannot meet the requirements of the manufacturing industry on the quality of the target.

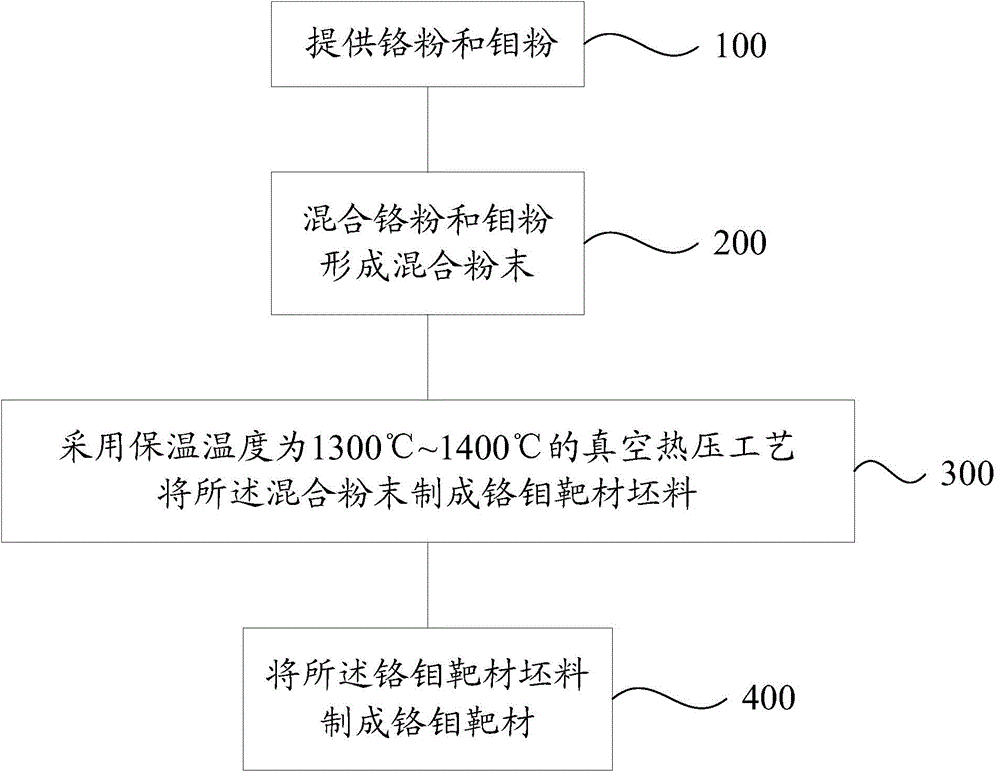

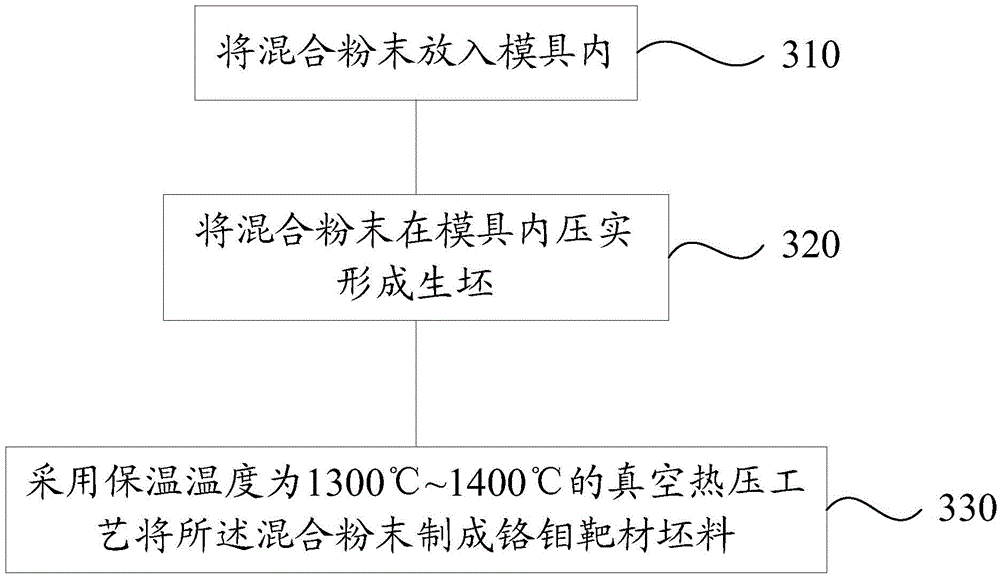

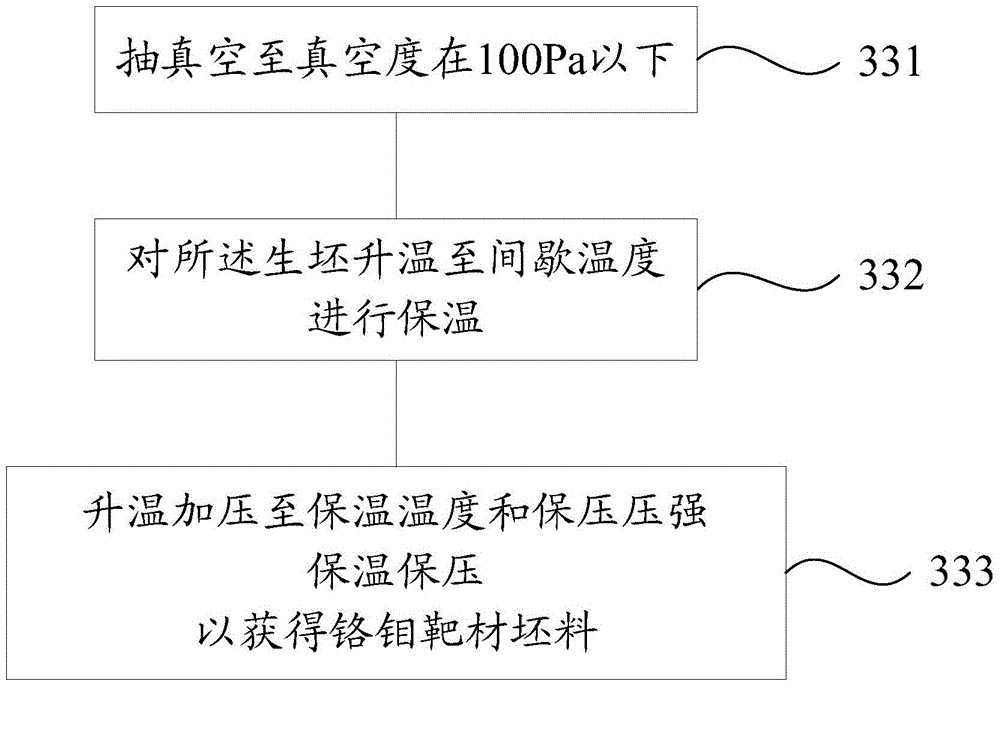

[0039] In order to solve the technical problem, the present invention provides a method for manufacturing a chromium-molybdenum target, comprising the following steps:

[0040] Provide chromium powder and molybdenum powder; mix the chromium powder and the molybdenum powde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com