Preparation method and application of carbon dot/gold composite nanoparticles

A technology of composite nanoparticles and carbon dots, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of low quantum yield of composite nanoparticles, large particle size of composite nanoparticles, limited heterogeneous nucleation, etc. The preparation process is simple and feasible, the quantum yield is high, and the reaction conditions are green and environmentally friendly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Example 1: Preparation of carbon dots

[0049] Weigh 2.0g citric acid monohydrate and 1.0g L-cysteine, add 10.0mL deionized water, stir until uniformly mixed; transfer the above mixed solution to a hydrothermal reaction kettle, and react in a muffle furnace at 200°C After 3h, it was naturally cooled to room temperature to obtain a brownish-yellow carbon dot solution. The obtained carbon dot solution was centrifuged at 5000r / min, the supernatant was taken, dialyzed with a dialysis bag (molecular weight cut-off of 3000Da) for 48h, evaporated and dried to obtain purified solid carbon dots, and refrigerated for future use.

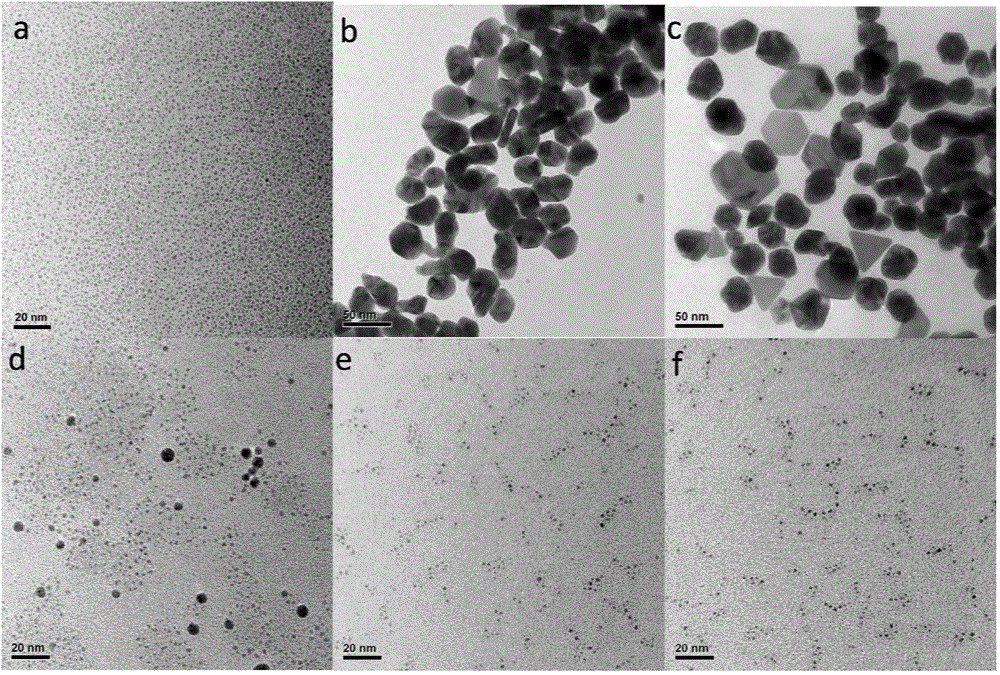

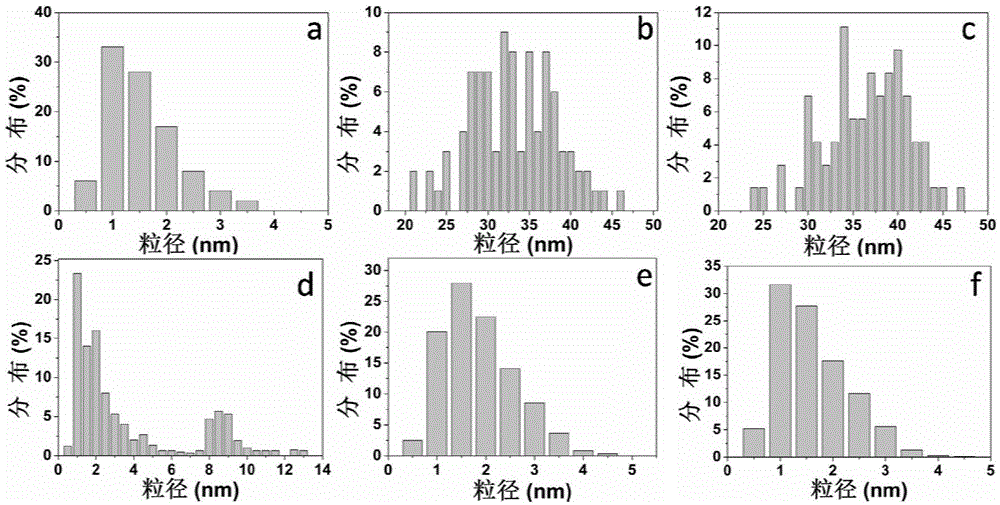

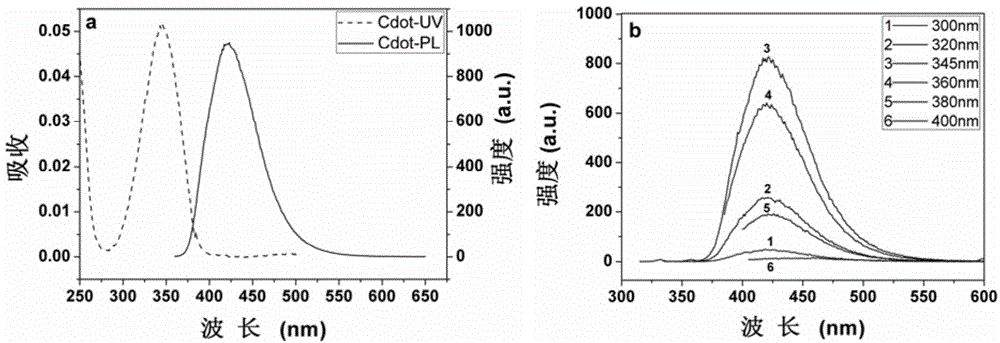

[0050] Depend on figure 1 a TEM image of carbon dots and figure 2 a The particle size distribution diagram shows that the particle size of most carbon dots is 1-2.5nm, which is smaller than the 7nm particle size reported in the literature, and the particle size distribution is quite uniform and in a monodisperse state. image 3 a is the UV-visible...

Embodiment 2

[0052] Embodiment 2: Preparation of Cdot-Au

[0053] 1. Preparation of raw carbon dots

[0054] The preparation method of carbon dots in this example is as shown in Example 1.

[0055] 2. Preparation and characterization of Cdot-Au

[0056] Prepare a chloroauric acid solution with a concentration of 100 μg / mL, take 5 mL, and slowly add it dropwise to 5 mL of a certain concentration of carbon dot solution to ensure that the mass ratio of carbon dots to chloroauric acid is 3:1. Slowly stir the reaction for 3 hours, then dialyze with a dialysis bag with a molecular weight cut-off of 1000-5000Da for 12-48 hours to obtain an aqueous solution of Cdot-Au nanocomposite particles, and obtain solid Cdot-Au nanocomposite particles after evaporation and drying.

[0057] The morphology of Cdot-Au, and the comparison with the structure and properties of carbon dots are as follows:

[0058] Cdot-Au described in the present invention is the particle of about 1~3nm under transmission elec...

Embodiment 3

[0066] Embodiment 3: to the regulation and control of Cdot-Au performance

[0067] 1. Preparation of raw carbon dots

[0068] The preparation method of carbon dots in this example is as shown in Example 1.

[0069] 2. The amount of carbon dots can control the performance of Cdot-Au

[0070] The effect of the amount of carbon dots on the particle size and optical properties of Cdot-Au was investigated by adjusting the amount ratio of carbon dots and chloroauric acid. like figure 1 b tofigure 1 f and 2b to figure 2 As shown in f, under the condition of maintaining the concentration of chloroauric acid at 50 μg / mL, when the mass ratio of carbon dots to chloroauric acid is 0.2:1 and 0.4:1, the particle diameter of the composite nanoparticles is about 35nm; when increased to 2 When : 1, obtain the nanoparticle of two kinds of size distributions, wherein particle size is bigger about 9nm, and smaller is about 2nm; When it is further increased to 4:1, the particle size is les...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com