Preparation method of 1,3-propane sulfone

A technology of propane sultone and sodium hydroxypropanesulfonate, applied in 1 field, can solve the problems of increased chloride ion content, large amount of solid waste, influence on product purity, etc., and achieves reduction of chloride ions, simple reaction raw materials, and improved conversion. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

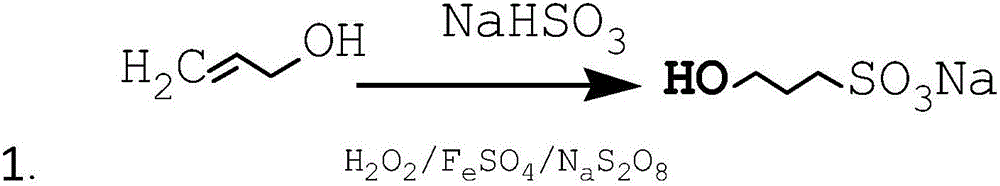

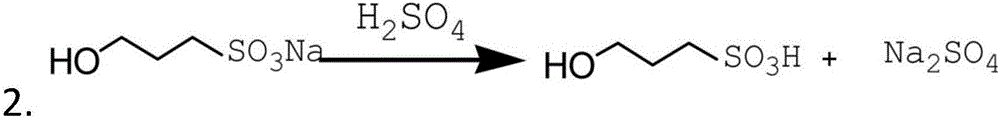

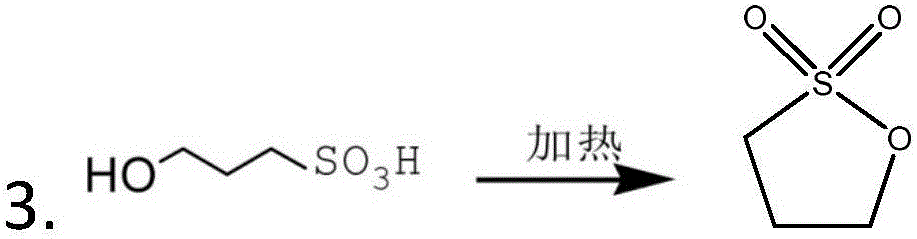

Method used

Image

Examples

Embodiment 1

[0022] (1) Add 104g (1mol) of sodium bisulfite and 312g of deionized water into a three-neck flask with mechanical stirring, thermometer, dropping device, and condenser, and stir, then add 58g of allyl alcohol dropwise at 30°C (1mol) and initiator, thereby reaction generates sodium 3-hydroxypropanesulfonate, initiator is mixed by sodium persulfate 11.9g, hydrogen peroxide 1.7g, ferrous sulfate 3.8g and deionized water 69.6g, drips Time 1 hour, be incubated 7 hours, analyze and sample then, after propenyl alcohol is reacted to below 0.2% of its consumption, reaction completes; (2) add sulfuric acid 50g ( 0.5mol) to carry out acidification, the acidification temperature is 50 ℃, and the acidification time is 2 hours, distills out excess water 254.4g after acidification finishes, then adds 600g dehydrated alcohol and carries out extraction and cooling filtration, thereby obtains the 3-hydroxypropanesulfonic acid Ethanol solution; (3) the ethanol solution of 3-hydroxypropanesulfon...

Embodiment 2

[0024] (1) Add 208g (2mol) of sodium bisulfite and 624g of deionized water into a three-neck flask with mechanical stirring, thermometer, dropping device, and condenser, and stir, then add 58g of allyl alcohol dropwise at 80°C (1mol) and initiator, thus react and generate sodium 3-hydroxypropanesulfonate, initiator is mixed by sodium persulfate 2.4g, hydrogen peroxide 0.34g, ferrous sulfate 0.76g and deionized water 14g, dropwise time 1 hour, insulation 2 hours, analysis and sampling then, after propenyl alcohol is reacted to below 0.2% of its consumption, the reaction is complete; (2) add sulfuric acid 50g (0.5 g) in the aqueous solution containing 3-hydroxy propane sulfonate that reaction obtains mol) for acidification, the acidification temperature is 60°C, and the acidification time is 1 hour. After the acidification ends, 320 g of excess water is distilled off, and then 800 g of absolute ethanol is added for extraction and cooled and filtered to obtain an ethanol solution ...

Embodiment 3

[0026](1) Add 156g (1.5mol) of sodium bisulfite and 468g of deionized water into a three-neck flask with mechanical stirring, thermometer, dropping device, and condenser, and stir, then add propenyl alcohol dropwise at 50°C 58g (1mol) and initiator, thus react and generate sodium 3-hydroxypropanesulfonate, initiator is mixed by sodium persulfate 7.2g, hydrogen peroxide 1.0g, ferrous sulfate 2.3g and deionized water 42g, dropwise Time 1 hour, insulation 4 hours, analysis and sampling then, after propenyl alcohol is reacted to below 0.2% of its consumption, reaction completes; (2) add sulfuric acid 50g ( 0.5mol) for acidification, the acidification temperature is 50°C, and the acidification time is 2 hours. After the acidification ends, 270 g of excess water is distilled off, and then 1200 g of absolute ethanol is added for extraction and cooling and filtration, thereby obtaining ethanol of 3-hydroxypropanesulfonic acid solution; (3) the ethanol solution of 3-hydroxypropanesulfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com