Methanol gasoline multi-phase corrosion inhibitor and methanol gasoline prepared from same

A technology of methanol gasoline and corrosion inhibitors, applied in the petroleum industry, fuel additives, liquid carbon-containing fuels, etc., can solve the problem of poor solubility and permeability of small molecular compounds, lack of prevention of gas-phase electrochemical corrosion, nitrous acid bicyclic Hexylamine high toxicity and other issues, to reduce metal oxidation and electrical conductivity, conducive to safety and environmental protection and healthy consumption, inhibition of electrochemical corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The preparation method of described methyl naphthalene bisquinoline quaternary ammonium salt may further comprise the steps:

[0036] (1) Dibromomethylnaphthalene and quinoline with a molar ratio of 1:2.11-1:2.20 are dropped into propanol whose mass is 4-5 times the total mass of dibromomethylnaphthalene and quinoline, mixed and dissolved to obtain a mixture ; The dibromomethylnaphthalene is 1,4-dibromomethylnaphthalene or 1,8-dibromomethylnaphthalene;

[0037](2) heating the mixture to 97-120° C., stirring and refluxing for 4-5 hours, discharging and cooling to obtain a crude product;

[0038] (3) The crude product was recrystallized twice with an anhydrous ethanol-ethyl acetate mixed solvent with a volume ratio of 2:1, filtered and dried to obtain a solid of methylnaphthalene bisquinoline quaternary ammonium salt.

[0039] The morpholine derivatives are N-methylmorpholine, fenfenmorpholine, 5,6-diphenyl-2-morpholinone, N-tert-butoxycarbonyl-(S)-2-morpholine methanol,...

Embodiment 1

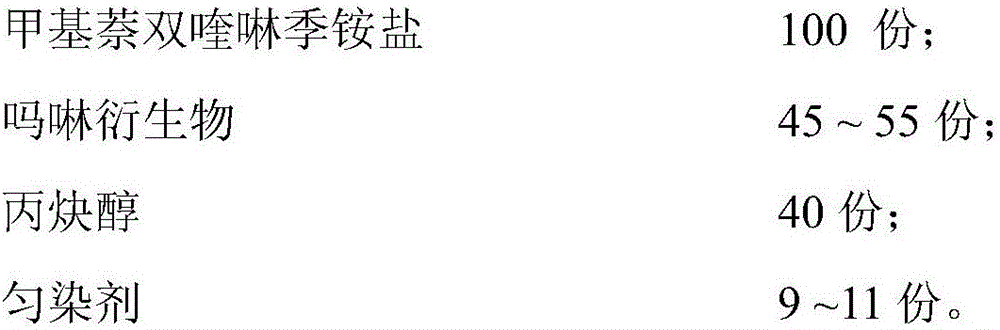

[0046] A multiphase corrosion inhibitor for methanol gasoline, which is formed by mixing the following components by volume:

[0047]

[0048] It is prepared by mixing components in parts by volume at 55°C.

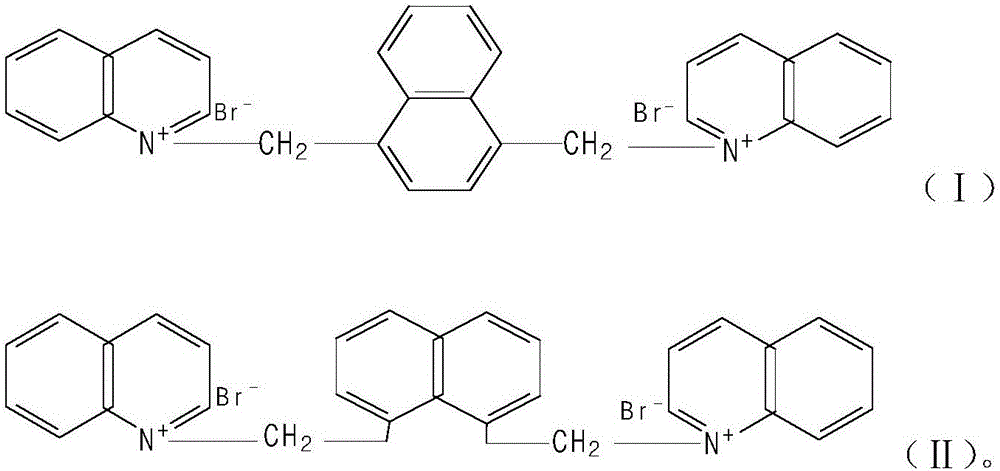

[0049] The structure of the 1,4-dibromomethylnaphthalene bisquinoline quaternary ammonium salt is shown in formula I.

[0050] The preparation method of described 1,4-dibromomethyl naphthalene bisquinoline quaternary ammonium salt comprises the following steps:

[0051] (1) Putting 1,4-dibromomethylnaphthalene and quinoline into 1,4-dibromomethylnaphthalene and quinoline with a molar ratio of 1:2.11 in propanol that is 4 times the total mass of 1,4-dibromomethylnaphthalene and quinoline, mixed and dissolved get the mixture;

[0052] (2) Heating the mixture to 108° C., stirring and refluxing for 4 hours, discharging and cooling to obtain a crude product;

[0053] (3) The crude product is recrystallized twice with a volume ratio of absolute ethanol-ethyl acetate mixed...

Embodiment 2

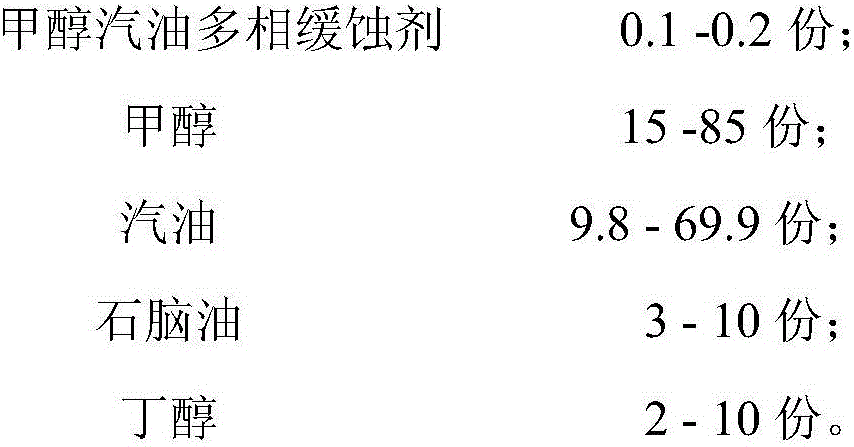

[0060] A multiphase corrosion inhibitor for methanol gasoline, which is formed by mixing the following components by volume:

[0061]

[0062] It is prepared by mixing components in parts by volume at 50°C.

[0063] The structure of the 1,8-dibromomethylnaphthalene bisquinoline quaternary ammonium salt is shown in formula II.

[0064] The preparation method of described 1,8-dibromomethyl naphthalene bisquinoline quaternary ammonium salt comprises the following steps:

[0065] (1) Put 1,8-dibromomethylnaphthalene and quinoline into 1,8-dibromomethylnaphthalene and quinoline with a molar ratio of 1:2.20 in propanol which is 5 times the total mass of 1,8-dibromomethylnaphthalene and quinoline, mix and dissolve get the mixture;

[0066] (2) Heating the mixture to 97° C., stirring and refluxing for 5 h, discharging and cooling to obtain a crude product;

[0067] (3) The crude product is recrystallized twice with a volume ratio of absolute ethanol-ethyl acetate mixed solvent o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com