Method for preparing 5-hydroxymethylfurfural (5-HMF) by catalyzing cellulose transformation in green solvent system

A technology of hydroxymethylfurfural and green solvents, which is applied in the development of new catalytic reaction systems, can solve problems such as low stability, difficulty in separation and extraction of 5-HMF, difficulty in separation and regeneration of catalysts, and achieve simple preparation process, easy operation and high efficiency conversion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

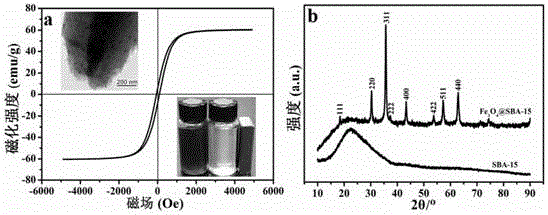

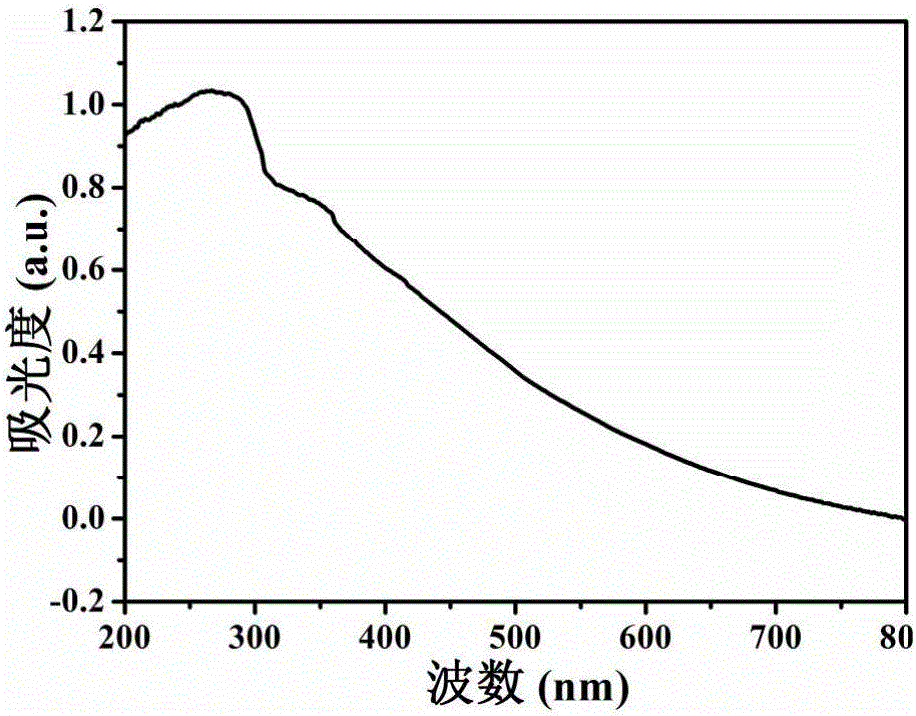

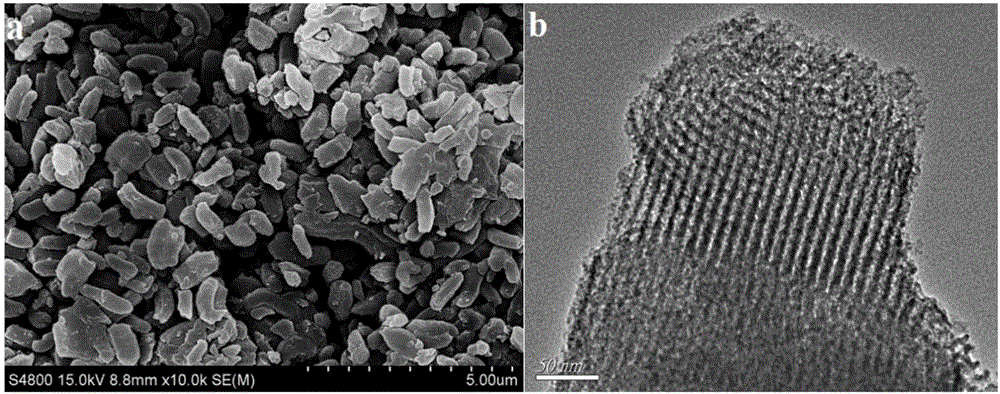

[0046] (1) Preparation of biological enzyme catalyst

[0047] 0.1g of FeCl 3 ·6H 2 O and 1.0g of NaAc were added to 30mL of ethylene glycol, and ultrasonically formed a uniformly mixed solution; then 0.2g of dried silicon-based mesoporous molecular sieve SBA-15 was dispersed in the above solution, and mixed with Add 0.4g PEG dropwise to the system, and put the mixed solution into the autoclave. After reacting at 100°C for 6h, the resulting solid is washed with water and ethanol, collected by centrifugation, and vacuum-dried at 40°C to obtain a magnetic Fe-loaded 3 o 4 SBA-15(Fe 3 o 4 @SBA-15).

[0048] Take 10mg of Fe obtained in the previous step 3 o 4 @SBA-15 was dispersed in 1mL of citric acid buffer solution with pH = 2.0. After mixing evenly, 0.4mg of cellulase was added to the mixed system under stirring. After the reaction system was reacted at 0°C for 12h, the obtained product was passed Collected by centrifugation and vacuum dried at 20°C to obtain the biologi...

Embodiment 2

[0068] (1) Preparation of biological enzyme catalyst

[0069] 4.0g of FeCl 3 ·6H 2 Add O and 20g of NaAc into 120mL of ethylene glycol, and ultrasonically form a uniformly mixed solution; then take 5.0g of dried silicon-based mesoporous molecular sieve SBA-15 and disperse it in the above solution. 10g of PEG was added dropwise in the solution, and the mixed solution was added to the autoclave, and reacted at 200°C for 24h. The resulting solid was washed with water and ethanol, collected by centrifugation, and vacuum-dried at 80°C to obtain a magnetic Fe-loaded 3 o 4 SBA-15(Fe 3 o 4 @SBA-15).

[0070] Get 50mg of Fe obtained in the previous step 3 o 4 @SBA-15 was dispersed in 5 mL of buffer solution of citric acid with pH=3.6. After mixing evenly, 2.5 mg of cellulase was added to the mixed system under stirring, and the reaction system was reacted at 5°C for 48 hours. Collected by centrifugation and vacuum-dried at 35°C to obtain the biological enzyme catalyst cellulase...

Embodiment 3

[0080] (1) Preparation of biological enzyme catalyst

[0081] 6.5g of FeCl 3 ·6H 2 Add O and 40g of NaAc into 200mL of ethylene glycol, and ultrasonically form a uniformly mixed solution; then take 10g of dried silicon-based mesoporous molecular sieve SBA-15 and disperse it in the above solution. Add 20g PEG drop by drop, and put the mixed solution into the autoclave. After reacting at 300°C for 48h, the obtained solid is washed with water and ethanol, collected by centrifugation, and vacuum-dried at 120°C to obtain a magnetic Fe-loaded 3 o 4 SBA-15(Fe 3 o 4 @SBA-15).

[0082] Get 100mg of Fe obtained in the previous step 3 o 4 @SBA-15 was dispersed in 10mL, pH=4.8 citric acid buffer solution. After mixing evenly, 5.0mg of cellulase was added to the mixed system under stirring conditions. After the reaction system was reacted at 10°C for 96h, the obtained product was passed Collected by centrifugation and vacuum dried at 50°C to obtain the biological enzyme catalyst ce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Magnetic strength | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com