Probiotic fermentation calcium supplement and preparation method thereof

A technology of probiotics and preparations, which is applied in the field of probiotic fermented calcium supplement preparations and its preparation, can solve the problems of side effects, potential safety hazards, and limited efficacy value of calcium products, and achieve the effects of easy absorption by the human body, long shelf life, and stable state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

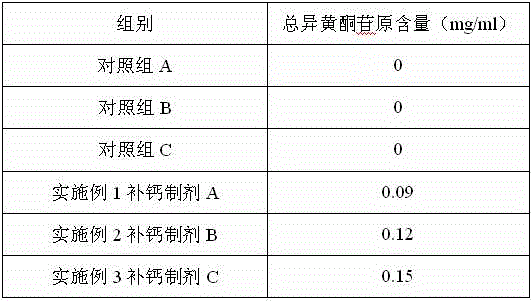

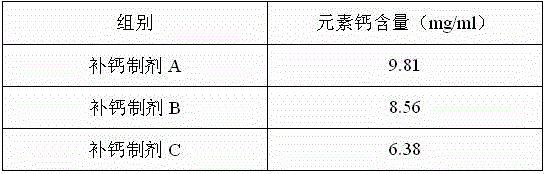

[0035] Example 1: Preparation of probiotic fermented calcium supplement preparation A

[0036] The specific preparation method is as follows:

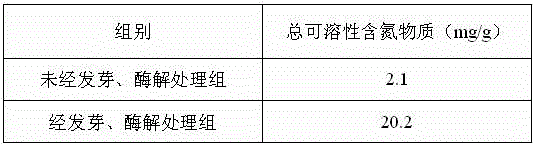

[0037] (1) Extraction: Select 2kg of dry soybeans, sprout them, add 100L water to the bean sprouts, grind them with a colloid mill, and extract under high pressure at 115°C for 60 minutes;

[0038] (2) Enzymatic hydrolysis: when the temperature drops to 45±2°C, maintain a constant temperature, adjust the pH to 8.0 with sodium hydroxide, add 20 g of trypsin, when the pH drops to 7.5, add 2 g of neutral protease, and when the pH drops to At 7.0, end the enzymatic hydrolysis, add glucose 10% (weight g / volume ml), peptone 0.2% (weight g / volume ml), calcium carbonate 2% (weight g / volume ml), autoclave at 115°C for 60 minutes, Obtain sterile enzymatic hydrolyzate;

[0039] (3) Inoculation and fermentation: When the temperature of the sterile enzymatic hydrolyzate drops to 39±2°C, inoculate pre-cultured Bifidobacterium breve (AS 1.2213) bac...

Embodiment 2

[0041] Example 2: Preparation of probiotic fermented calcium supplement preparation B

[0042] The specific preparation method is as follows:

[0043] (1) Extraction: Select 4kg of dry soybeans, sprout them, add 100L water to the bean sprouts, grind them through a colloid mill, and extract under high pressure at 115°C for 60 minutes;

[0044] (2) Enzymatic hydrolysis: when the temperature drops to 45±2°C, maintain a constant temperature, adjust the pH to 8.0 with sodium hydroxide, add 40 g of trypsin, when the pH drops to 7.5, add 4 g of neutral protease, and when the pH drops to At 7.0, end the enzymatic hydrolysis, add glucose 8% (weight g / volume ml), peptone 0.4% (weight g / volume ml), calcium carbonate 3% (weight g / volume ml), autoclave at 115°C for 60 minutes, Obtain sterile enzymatic hydrolyzate;

[0045] (3) Inoculation and fermentation: When the temperature of the sterile enzymatic hydrolyzate drops to 39±2°C, inoculate under aseptic conditions pre-cultured Bifidobact...

Embodiment 3

[0047] Example 3: Preparation of probiotic fermented calcium supplement preparation C

[0048] The specific preparation method is as follows:

[0049] (1) Extraction: Select 6kg of dry soybeans, sprout them, add 100L water to the bean sprouts, grind them through a colloid mill, and extract under high pressure at 115°C for 60 minutes;

[0050] (2) Enzymatic hydrolysis: when the temperature drops to 45±2°C, maintain a constant temperature, adjust the pH to 8.0 with sodium hydroxide, add 60 g of trypsin, when the pH drops to 7.5, add 6 g of neutral protease, and when the pH drops to At 7.0, end the enzymatic hydrolysis, add glucose 6% (weight g / volume ml), peptone 0.5% (weight g / volume ml), calcium carbonate 4% (weight g / volume ml), autoclave at 115°C for 60 minutes, Obtain sterile enzymatic hydrolyzate;

[0051] (3) Inoculation and fermentation: When the temperature of the sterile enzymatic hydrolyzate drops to 39±2°C, inoculate pre-cultured Bifidobacterium breve (AS 1.2213) b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com