Frozen gel three-dimensional structural body, preparation method and application thereof

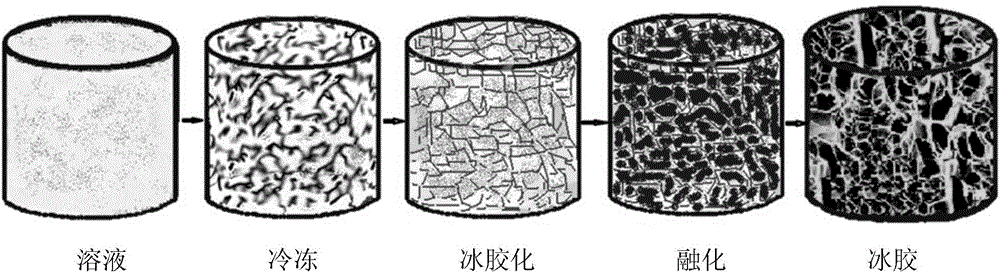

A structure and ice glue technology, applied in the field of tissue engineering and three-dimensional printing, can solve the problems of difficult to build three-dimensional structure, uncontrollable internal structure, uncontrollable material distribution, etc. High volume and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

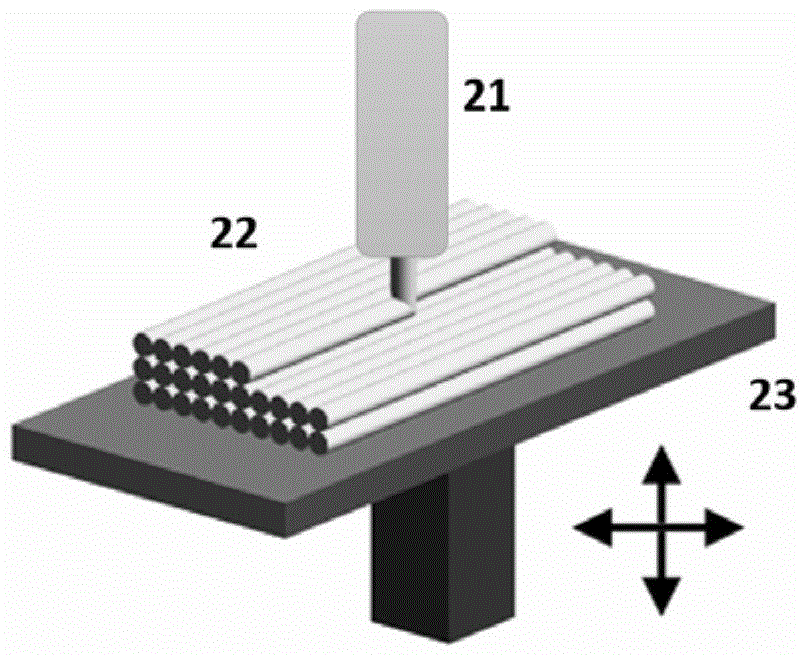

[0068] Example 1 Preparation of cryogel 3D structure by 3D printing with a single nozzle

[0069] 1. Sodium alginate powder (Sigma-Aldrich) was dissolved in deionized water to make a 3% homogeneous solution, and sterilized by filtering through 45 μm filter paper.

[0070] 2. Mix 2mL of sodium alginate solution prepared as above with 0.2mL of calcium chloride solution (100mmol -1 ) were uniformly mixed to form a precursor solution with a certain viscosity and loaded into a 1 mL disposable sterile syringe.

[0071] 3. Load the sterile syringe into the biological three-dimensional printing device (see Rui Yao, et al., In Vitro Angiogenesis of 3D Tissue Engineered Adipose Tissue, Journal of Bioactive and Compatible Polymer, 2009; 24:5), at room temperature, Under the control of computer software (Microsoft, AT640, Redmond, WA), with the stepper motor speed of 2mm / s and the scanning speed of 10mm / s, three-dimensional printing was performed on a sterile flat platform to form a volu...

Embodiment 2

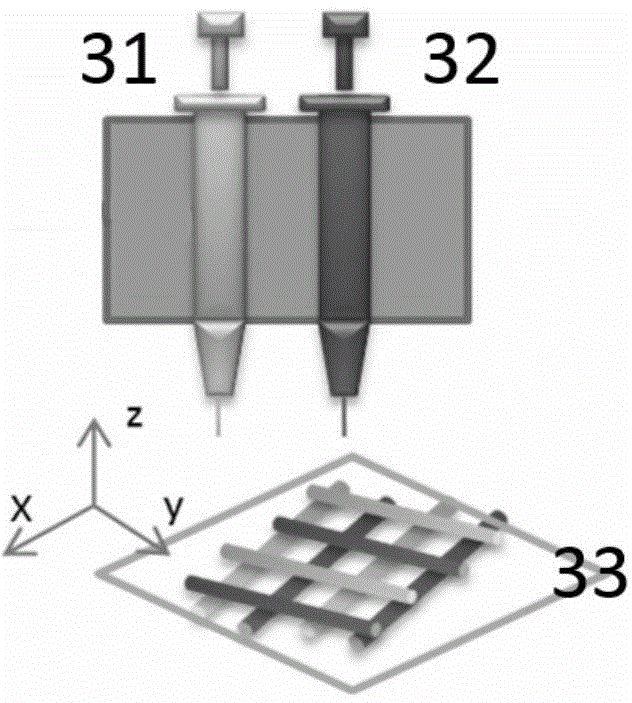

[0076] Example 2 Preparation of cryogel three-dimensional structure by dual-nozzle three-dimensional printing

[0077] 1. Sodium alginate powder (Sigma-Aldrich) was dissolved in deionized water to make a 3% homogeneous solution, and sterilized by filtering through 45 μm filter paper.

[0078] 2. The gelatin powder is dissolved in deionized water to make a 10% homogeneous solution, which is stored at room temperature after repeated high-temperature sterilization.

[0079] 3. Mix 2 mL of the sodium alginate solution prepared above with 0.2 mL of the calcium chloride solution (100 mmol -1 ) were uniformly mixed to form a precursor solution with a certain viscosity and loaded into a 10 mL disposable sterile syringe.

[0080] 4. Load 2 mL of the gelatin solution prepared as above into a 10 mL disposable sterile syringe and store at 10° C. for 10 min to form a gelatin precursor solution with a certain viscosity.

[0081] 5. Load the sterile syringes loaded with the sodium alginate...

Embodiment 3

[0086] Example 3 Preparation of cell-loaded cryogel three-dimensional structure using collagen-containing cell culture medium

[0087] 1. Sodium alginate powder (Sigma-Aldrich) was dissolved in deionized water to make a 3% homogeneous solution, and sterilized by filtering through 45 μm filter paper.

[0088] 2. Mix 2mL of sodium alginate solution prepared as above with 0.2mL of calcium chloride solution (100mmol -1 ) were uniformly mixed to form a precursor solution with a certain viscosity and loaded into a 1 mL disposable sterile syringe.

[0089] 3. Load the sterile syringe into the biological three-dimensional printing equipment, under the control of computer software (Microsoft, AT640, Redmond, WA) at room temperature, with the parameter conditions of stepping motor speed 2mm / s and scanning speed 10mm / s 3D printing on a sterile flat platform to form a pregel 3D structure with a volume of 1cm / 1cm / 0.5cm (for the structure of the 3D printer, please refer to Rui Yao, et al.,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com