Method for preparing composite bone cement bracket

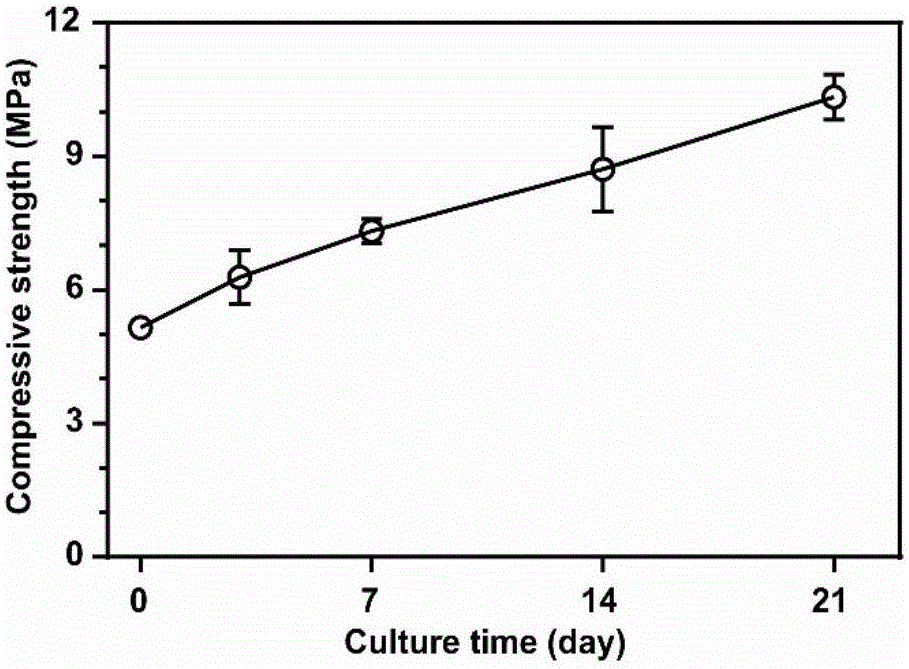

A technology of bone cement and ink, applied in the field of materials science, can solve the problems of poor mechanical support performance, degradability and biological activity, and the inability to precisely control the connectivity of scaffold holes, so as to achieve high mechanical strength and promote proliferation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A preparation method of a composite bone cement support, comprising the following steps:

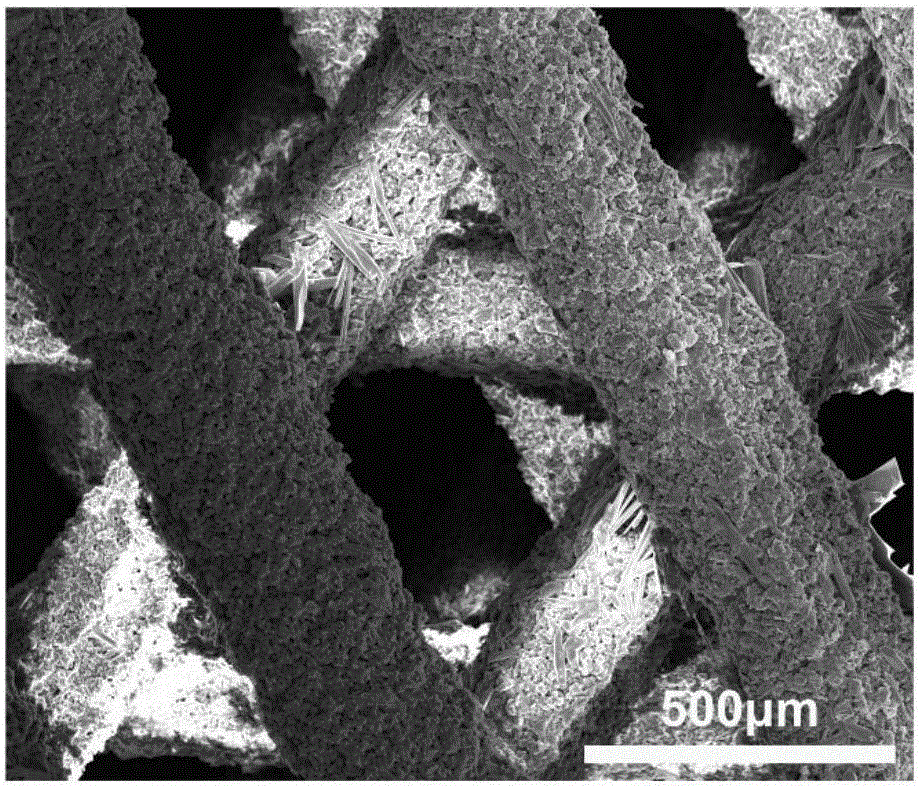

[0022] Step 1, preparing CSH / MBG composite printing ink. Mix CSH and MBG powder evenly at a mass ratio of 80:20, pass through a 400-mesh sieve, and then take 1.8 grams of mixed vermicelli and add it to 2 ml of polycaprolactone (PCL) / dichloromethane solution (0.1g / ml) In the middle, stir quickly evenly, and then seal and store.

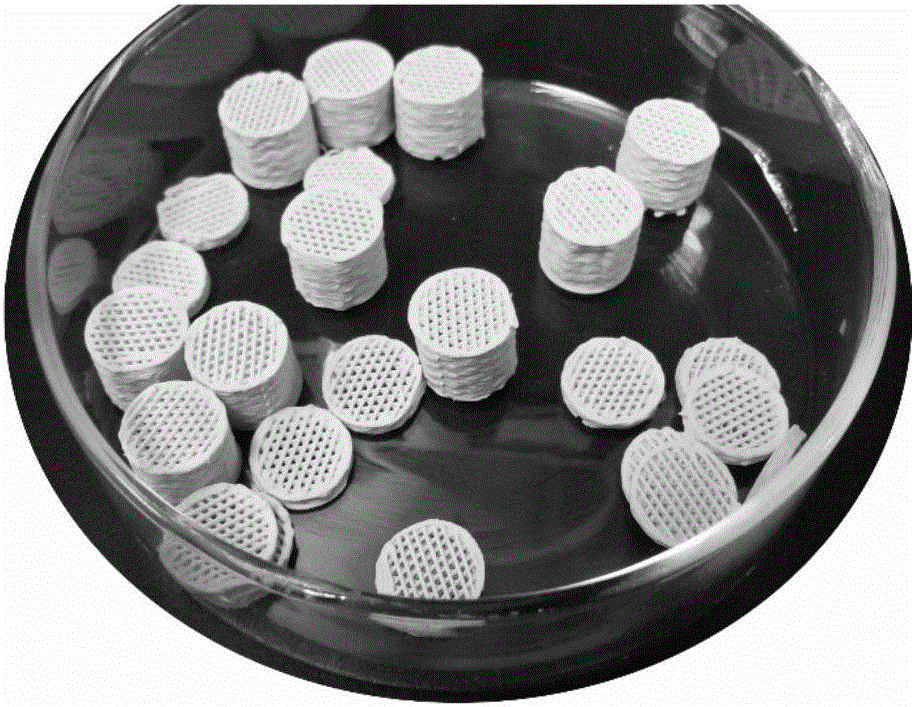

[0023] Step 2, designing the appearance and internal structure of the CSH / MBG composite bone cement scaffold. Use CAD / CAM and other computer-aided software to design the appearance and internal structure of the bracket. The bracket model is a cylinder (φ=8mm, h=2mm), the inner diameter is 400μm, and the angle between two adjacent layers of ink is 60°.

[0024] Step 3, low temperature 3D printing technology to prepare CSH / MBG composite bone cement scaffold. Put the prepared printing ink into the barrel of the 3D printer, then install a needle with a diam...

Embodiment 2

[0027] A preparation method of a composite bone cement support, comprising the following steps:

[0028] Step 1, preparing CSH / MBG composite printing ink. Mix CSH and MBG powder evenly at a mass ratio of 70:30, pass through a 600-mesh sieve, and then take 1.8 grams and add it to 2.5 ml of polycaprolactone (PCL) / chloroform solution (0.1g / ml) , Stir quickly and evenly, then seal and store.

[0029] Step 2, designing the appearance and internal structure of the CSH / MBG composite bone cement scaffold. Use CAD / CAM and other computer-aided software to design the appearance and internal structure of the bracket. The bracket model is a cylinder (φ=8mm, h=8mm), the inner diameter is 200μm, and the angle between two adjacent layers of ink is 60°.

[0030] Step 3, low temperature 3D printing technology to prepare CSH / MBG composite bone cement scaffold. Put the prepared printing ink into the barrel of the 3D printer, then install a needle with a diameter of 200 microns, and pre-cool at...

Embodiment 3

[0033] A preparation method of a composite bone cement support, comprising the following steps:

[0034] Step 1, preparing CSH / MBG composite printing ink. Mix CSH and MBG powder evenly at a mass ratio of 60:40, pass through a 300-mesh sieve, and then take 1.8 grams and add it to 2 ml of polycaprolactone (PCL) / dichloromethane solution (0.1g / ml) , Stir quickly and evenly, then seal and store.

[0035] Step 2, designing the appearance and internal structure of the CSH / MBG composite bone cement scaffold. Use CAD / CAM and other computer-aided software to design the appearance and internal structure of the bracket. The bracket model is a cylinder (φ=8mm, h=2mm), the inner diameter is 600μm, and the angle between two adjacent layers of ink is 90°.

[0036] Step 3, low temperature 3D printing technology to prepare CSH / MBG composite bone cement scaffold. Put the prepared printing ink into the barrel of the 3D printer, then install a needle with a diameter of 600 microns, pre-cool at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Internal aperture | aaaaa | aaaaa |

| Internal aperture | aaaaa | aaaaa |

| Internal aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com