Multi-component composite photocatalyst and preparation method and application thereof

A composite light and catalyst technology, applied in separation methods, chemical instruments and methods, chemical elements of heterogeneous catalysts, etc., can solve the problems of poor controllability of active particle size, easy aggregation of active components, and low utilization of light energy. , to achieve the effect of improving performance and applicability, small particle size, and high utilization of light energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

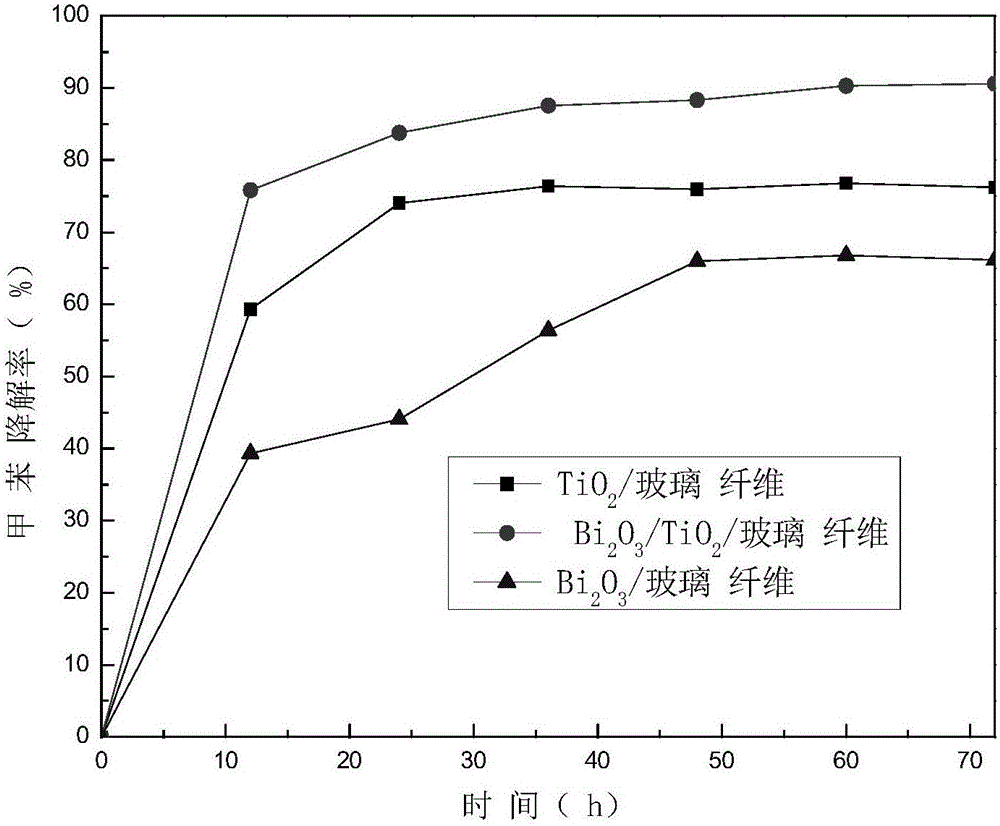

Embodiment 1

[0018] A preparation method and application of a multi-component composite photocatalyst, comprising the following steps:

[0019] (1) 1 g of terephthalic acid was dissolved in 40 mL of N,N-dimethylformamide, and a clear solution was obtained after stirring at room temperature for 10 min.

[0020] (2) Add 0.8g Bi(NO 3 ) 3 ·5H 2 O, stirred at room temperature for 20 min to obtain a mixed solution for subsequent use.

[0021] (3) Put 8 g of glass fibers into the mixed solution described in step (2) and soak at a constant temperature of 100° C. for 2 hours to obtain MOFs / glass fibers for later use.

[0022] (4) Dissolve 30 mL of tetrabutyl titanate in 15 mL of absolute ethanol and stir for 15 min. Put the treated MOFs / glass fiber material obtained in step (3) into the tetrabutyl titanate solution, carry out loading, and set aside. The above treatment method is to wash the MOFs / glass fiber material with ethanol, methanol or N,N-dimethylformamide, then wash with distilled wate...

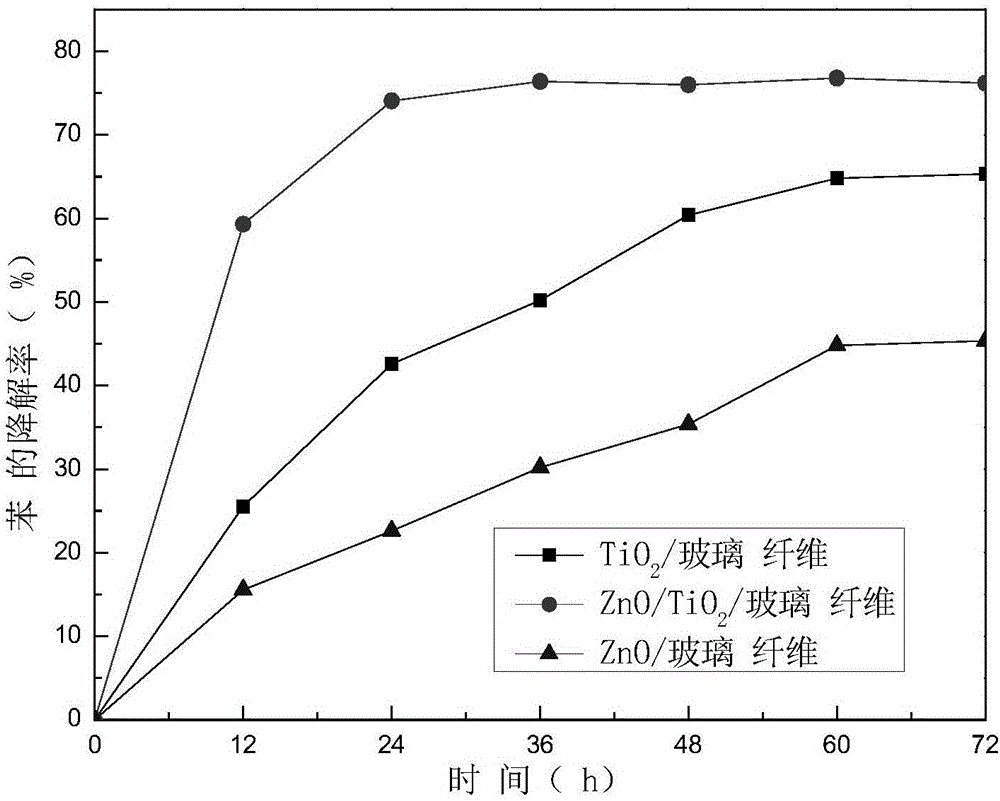

Embodiment 2

[0029] A preparation method and application of a multi-component composite photocatalyst, comprising the following steps:

[0030] (1) Dissolve 0.5g of terephthalic acid in 25mL of N,N-dimethylformamide, stir at room temperature for 15min to obtain a clear solution, and set aside.

[0031] (2) Add 0.35g Zn(NO 3 ) 2 ·6H 2 O, stirred at room temperature for 15 min to obtain a mixed solution for subsequent use.

[0032] (3) Put 8 g of glass fibers into the mixed solution described in step (2) and soak at a constant temperature of 120° C. for 2 hours to obtain MOFs / glass fibers for later use.

[0033] (4) Dissolve 30 mL of tetrabutyl titanate in 15 mL of absolute ethanol, and stir for 10 min. Put the treated MOFs / glass fiber material obtained in step (3) into tetrabutyl titanate for loading, and set aside. The above treatment method is to wash the MOFs / glass fiber material with ethanol, methanol or N,N-dimethylformamide, then wash with distilled water or deionized water and d...

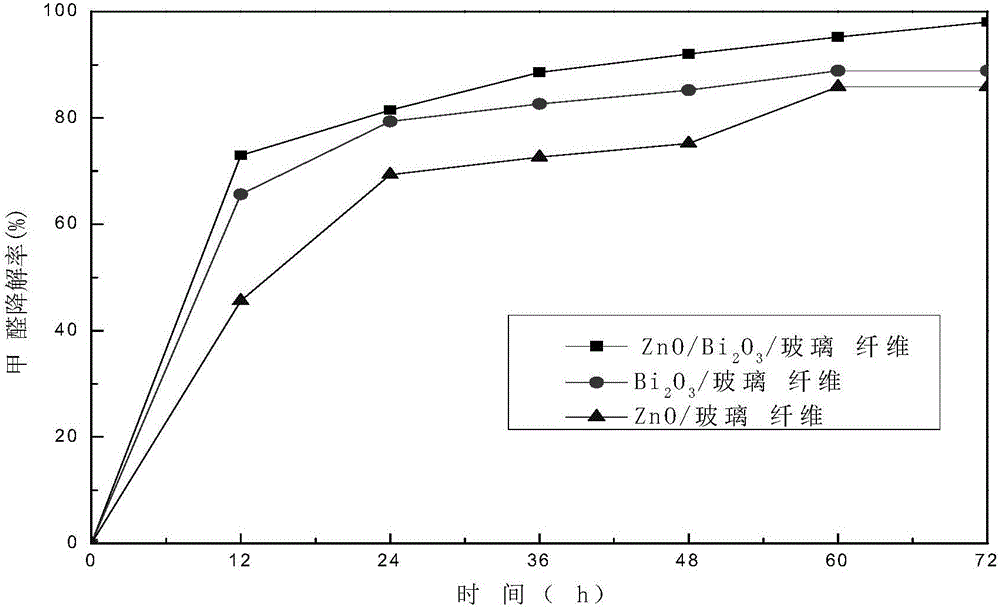

Embodiment 3

[0037] A preparation method of a multi-component composite photocatalyst, comprising the following steps:

[0038] (1) Dissolve 0.8g of terephthalic acid in 30mL of N,N-dimethylformamide, stir at room temperature for 13min to obtain a clear solution, and set aside.

[0039] (2) Add 0.35g Zn(NO 3 ) 2 ·6H 2 O, stirred at room temperature for 15 min to obtain a mixed solution for subsequent use.

[0040] (3) Put 8 g of glass fibers into the mixed solution described in step (2) and soak at a constant temperature of 120° C. for 2 hours to obtain MOFs / glass fibers for later use.

[0041] (4) 35g Bi(NO 3 ) 3 ·5H 2O was dissolved in 15 mL of absolute ethanol and stirred for 13 min. Put the treated MOFs / glass fiber material obtained in step (3) into a bismuth nitrate solution for loading, and set aside. The above treatment method is to wash the MOFs / glass fiber material with ethanol, methanol or N,N-dimethylformamide, then wash with distilled water or deionized water and dry at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com